Golden paper stove

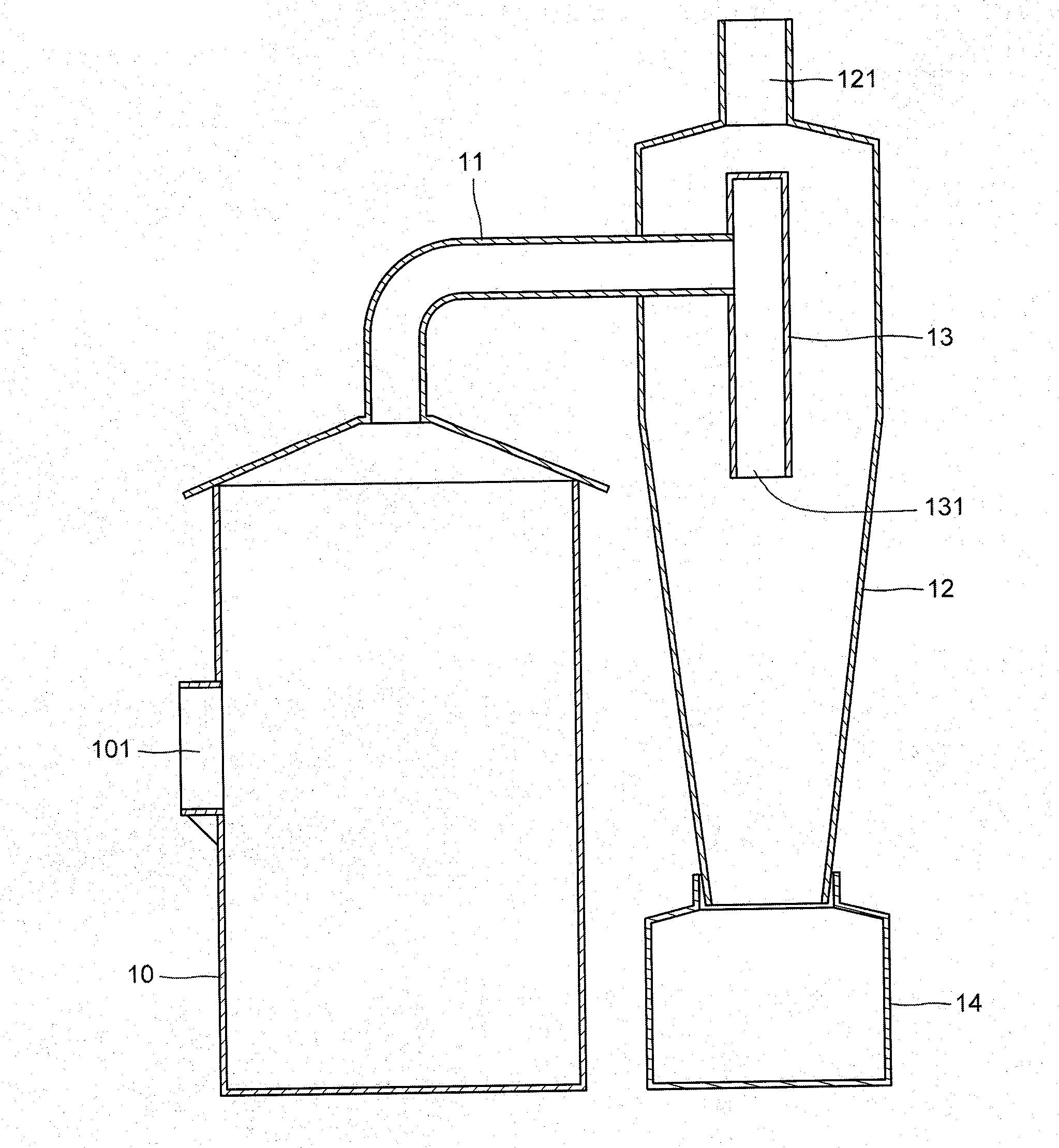

A technology of stoves and gold paper, which is applied to home appliances, household appliances, religious or ritual appliances, etc., can solve the problems of turbulent flow, personal touch burns, space occupation, etc., to achieve volume reduction, reduce waste, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

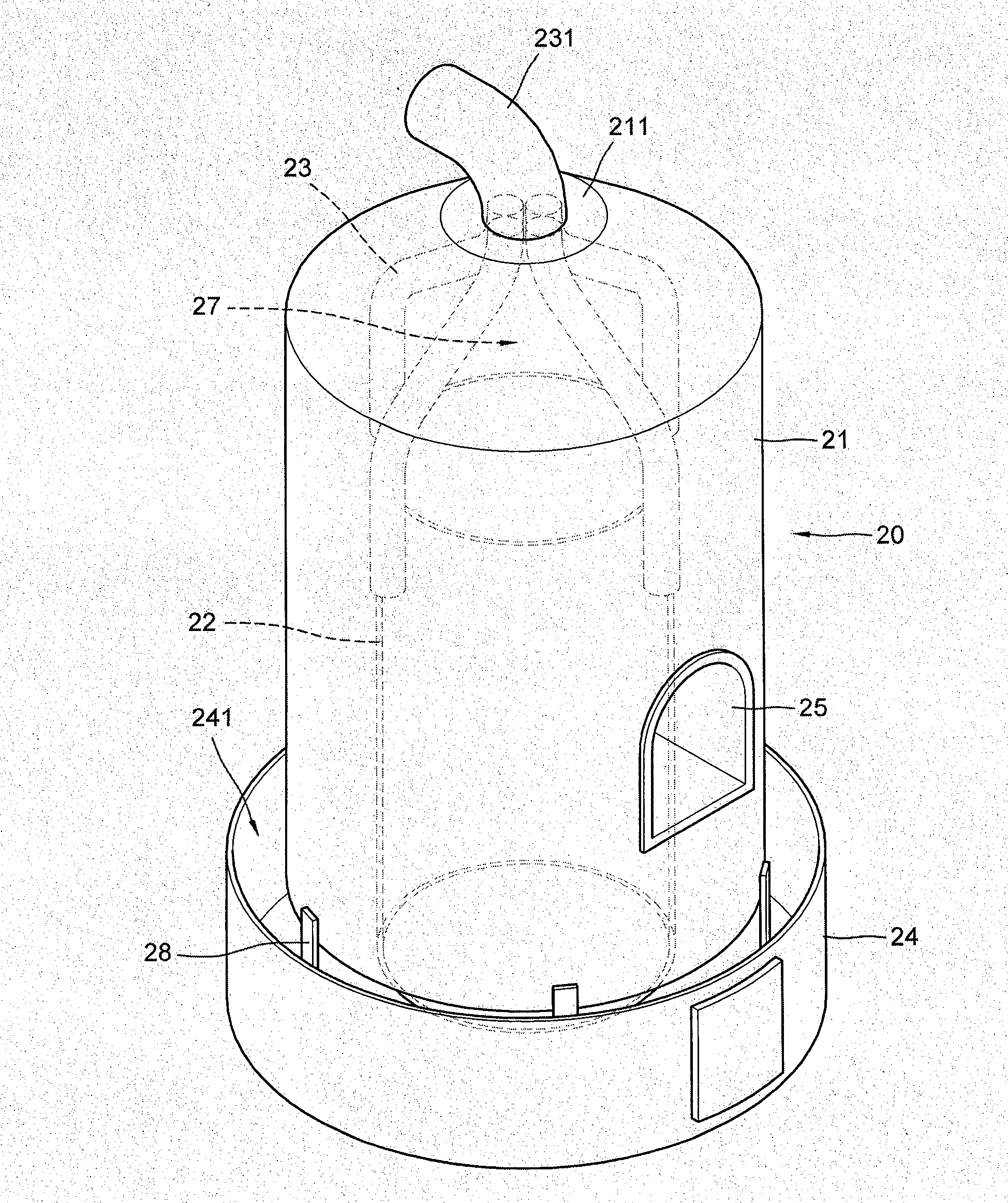

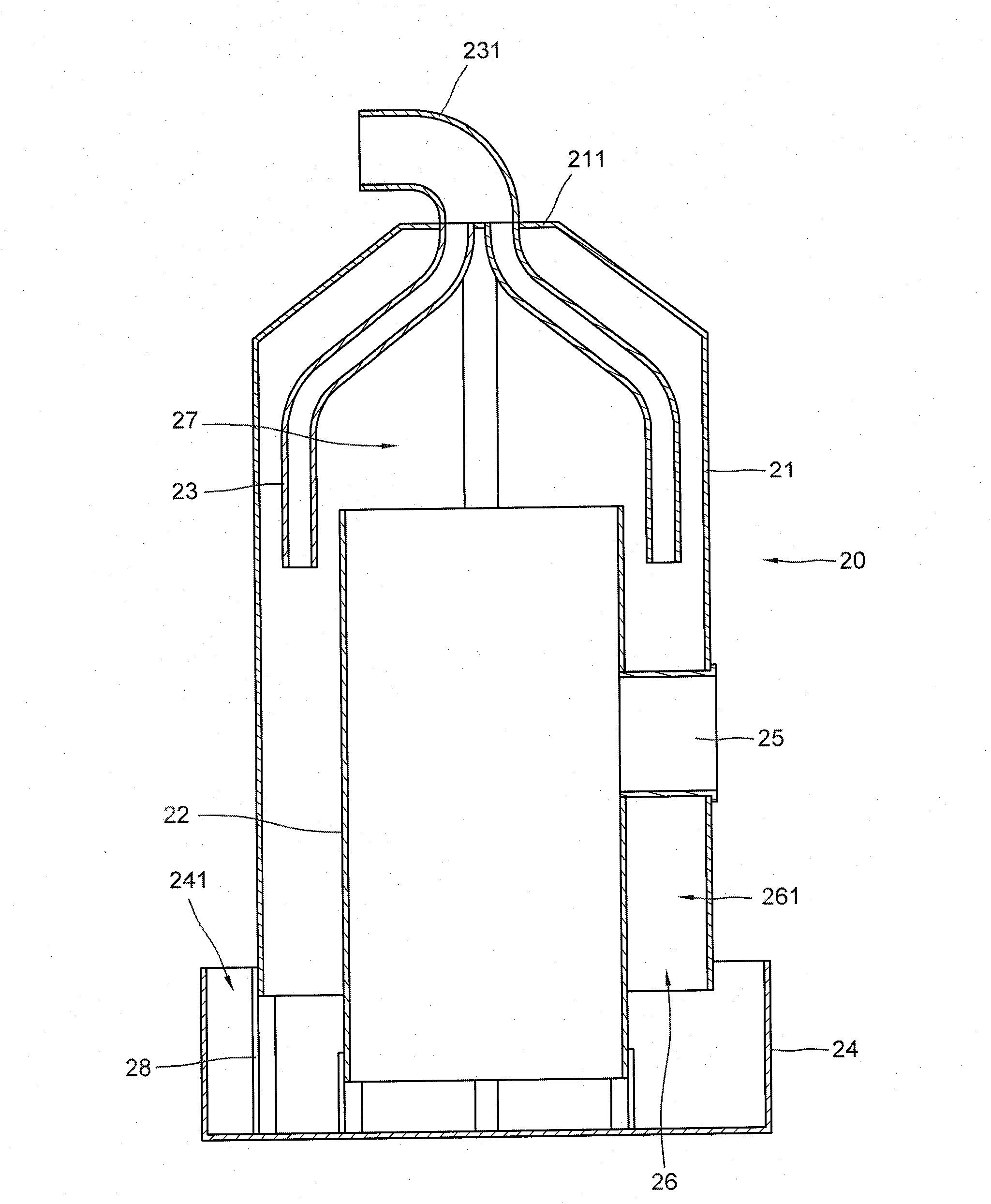

[0042] First of all, a gold paper stove of the present invention, such as figure 2 , 3 As shown, it is a stove main body 20, which includes an outer cylinder 21, an inner cylinder 22, several exhaust pipes 23 and a collection cylinder 24. The outer cylinder 21 is cylindrical, and can be cylindrical or square. Yes, the outer cylinder 21 has a heat insulation layer, a furnace mouth 25 is arranged on the outside, an air inlet 26 is provided at the bottom, and a sealing plate 211 is provided at the top for sealing;

[0043] The inner cylinder 22 is located inside the outer cylinder 21, and the height of the inner cylinder 22 is lower than that of the outer cylinder 21. There is a distance between the outer circumference of the inner cylinder 22 and the inner circumference of the outer cylinder 21 to form an air intake space 261. The furnace mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com