Regenerative and integrative hydrogen sulfide liquid phase oxidation absorption method of sulphur separation/desulfuration solution

A technology of desulfurization solution and liquid-phase oxidation, which is applied in the direction of refining with oxygenated compounds, can solve the problems of increasing the loss of desulfurization agent, unsatisfactory separation effect, etc., and achieves the effect of high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

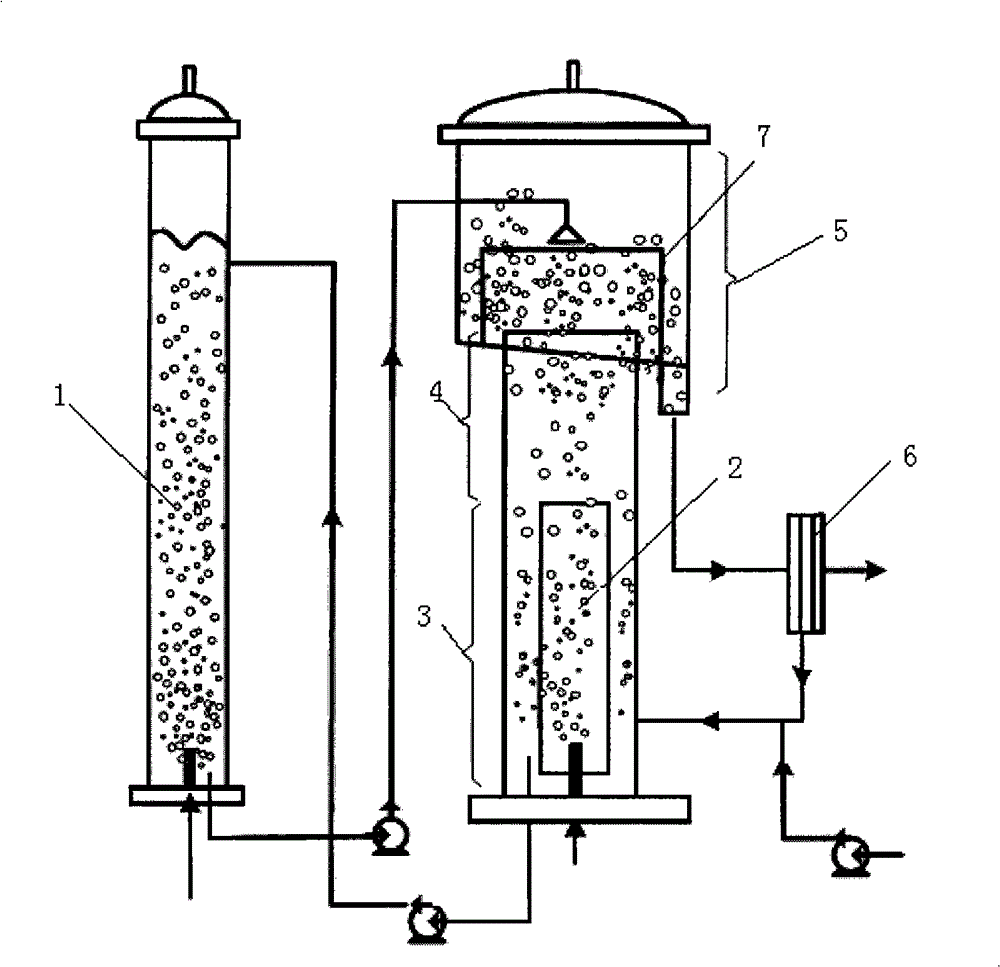

Image

Examples

Embodiment 1

[0024] The absorption tower is a bubbling tower with an effective volume of 12L; the volume of the bubbling reaction section of the regeneration-separation tower is 25L, the diameter of the bubbling reaction section: the diameter of the gas-liquid separation section: the diameter of the foam collecting section = 1:1:1.43, the height of the bubbling reaction section : The height of the gas-liquid separation section: the height of the foam collection section=1: 0.4: 0.8 (the volume of the foam collection section can be calculated to be 160% of the bubbling reaction section). The diameter ratio of the overflow tank weir in the foam collection section to the foam collection section is 1:1.2, and the ratio of the overflow tank weir height to the total height of the foam collection section is 0.4:1. The flow rate of the purified gas is 0.5m 3 / h (standard condition), H 2 The content of S is 1.0% (volume fraction); the concentration of complexed iron ions in the desulfurization solu...

Embodiment 2

[0026] The device is the same as in Example 1. The flow rate of the purified gas is 0.8m 3 / h (standard condition), H 2 The content of S is 2.0% (volume fraction); the concentration of complexed iron ions in the desulfurization solution is 30mol / m 3 , the circulating flow rate of the desulfurization solution between the two towers is 60L / h. The amount of desulfurization solution in the regeneration-separation tower is kept at 26-28L (it can be seen that the residence time of the desulfurization solution containing 1g of sulfur powder in the regeneration-separation tower is 1.2h), and the superficial gas velocity is 1.7cm / s. SDBS is used as the active agent, and the flow rate is as follows: 0.012g of surfactant is newly added for every desulfurization solution containing 1g of sulfur entering the regeneration-separation tower. After the system runs stably, the pH is maintained at 9.0-9.5, and the H in the gas at the outlet of the absorption tower 2 The S content is less tha...

Embodiment 3

[0028] The absorption tower is a bubble tower with an effective volume of 12L; the volume of the bubble reaction section of the regeneration-separation tower is 27L, the diameter of the bubble reaction section: the diameter of the gas-liquid separation section: the diameter of the foam collection section = 1:1:1.7, the height of the bubble reaction section : The height of the gas-liquid separation section: the height of the foam collection section=1: 0.25: 0.4 (the volume of the foam collection section can be calculated to be 120% of the bubbling reaction section). The diameter ratio of the overflow tank weir in the foam collection section to the foam collection section is 1:1.4, and the ratio of the overflow tank weir height to the total height of the foam collection section is 0.2:1. H in the purified gas 2 The content of S is 1.0% (volume fraction), the gas flow rate is 1m 3 / h (standard condition); the concentration of complexed iron ions in the desulfurization solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com