Wind-proofing sand-blocking device

A technology of windshield and sand baffle, which is applied in the direction of protective equipment and buildings, and can solve the problems of weakened airflow sand-carrying ability, general sand-blocking effect, and sand barriers are easy to be buried, so as to reduce sand-carrying ability and sand-proof effect Good, simple and practical effect of component installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

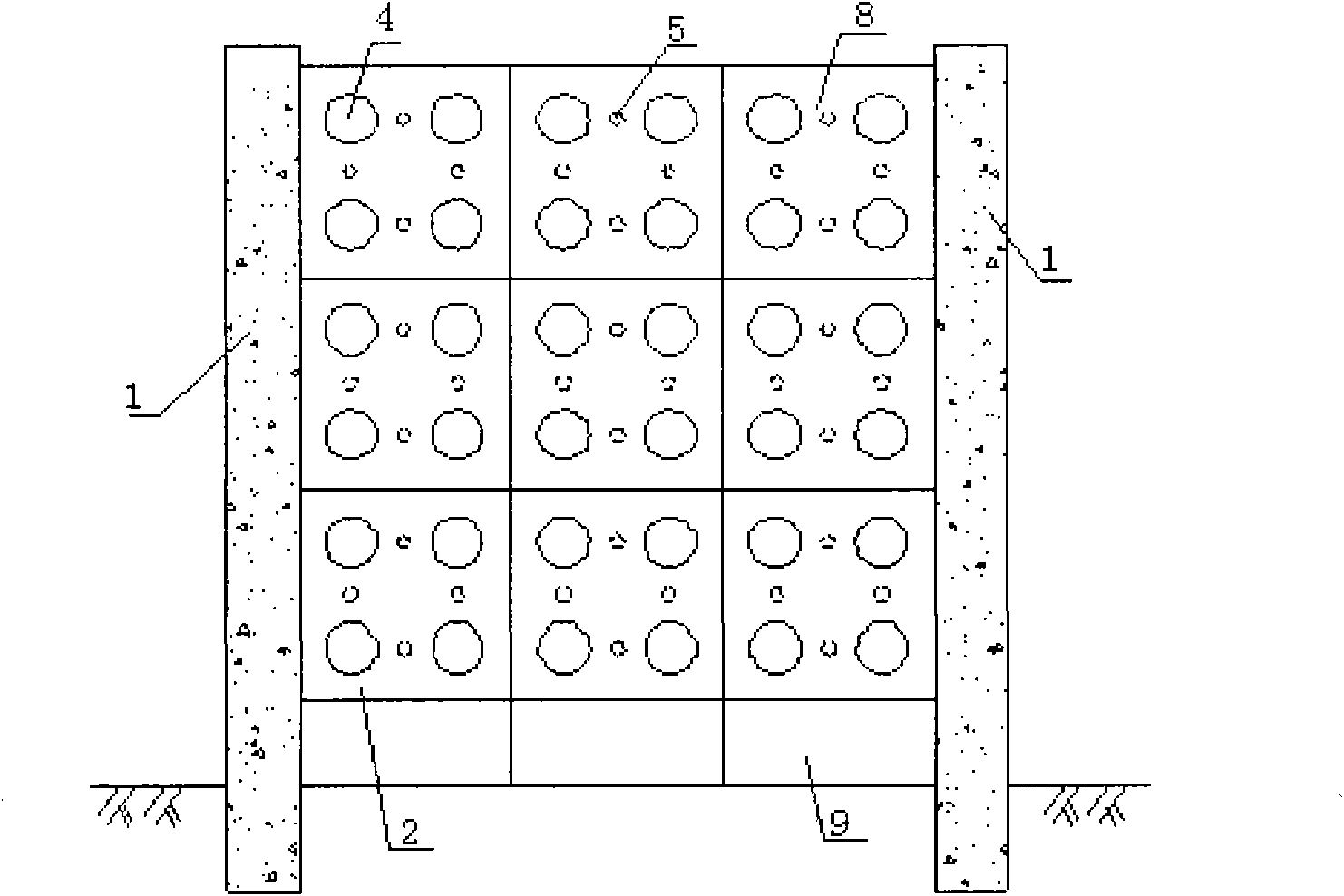

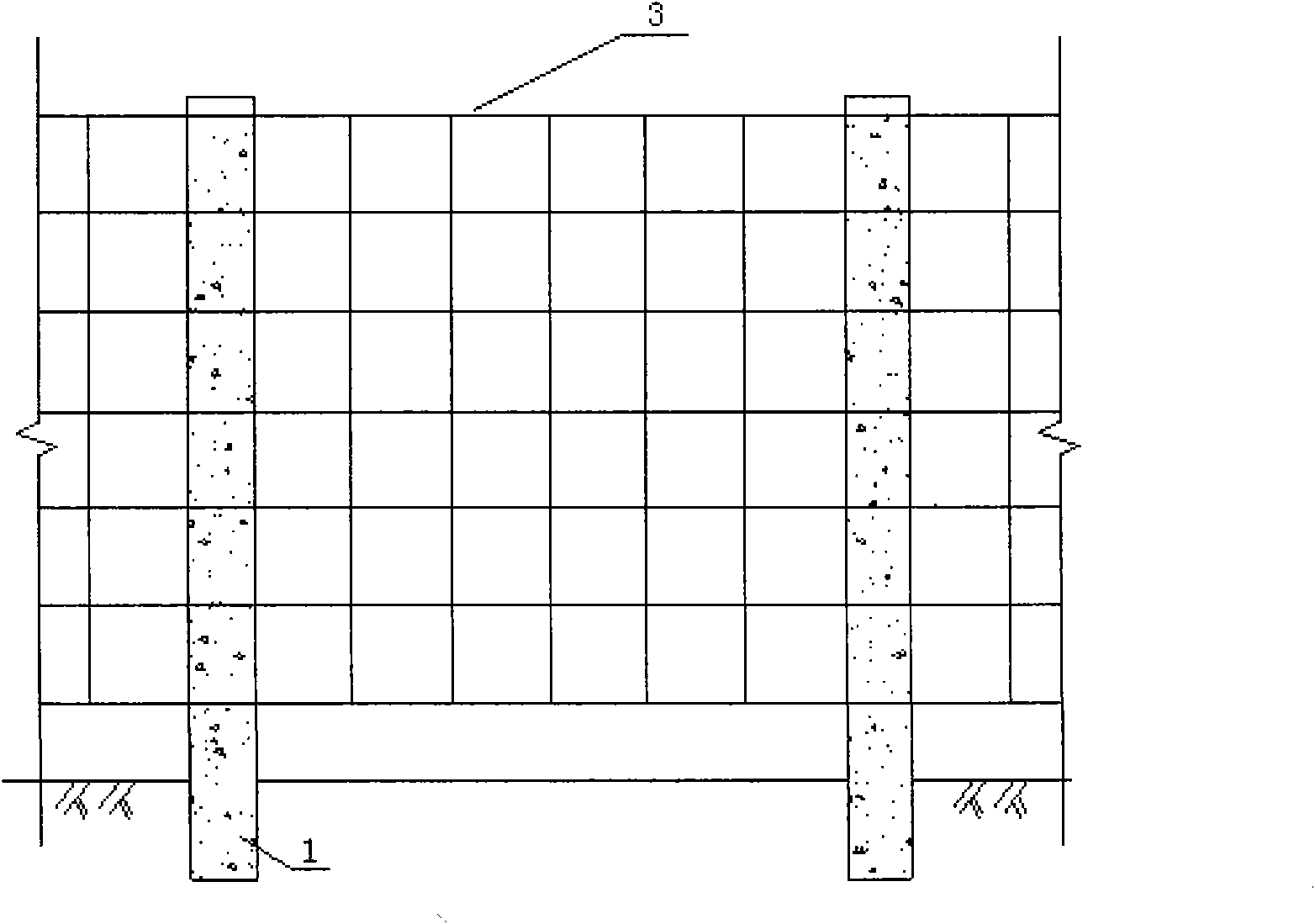

[0032] Accompanying drawing is embodiment of the present invention. Below in conjunction with accompanying drawing explanation.

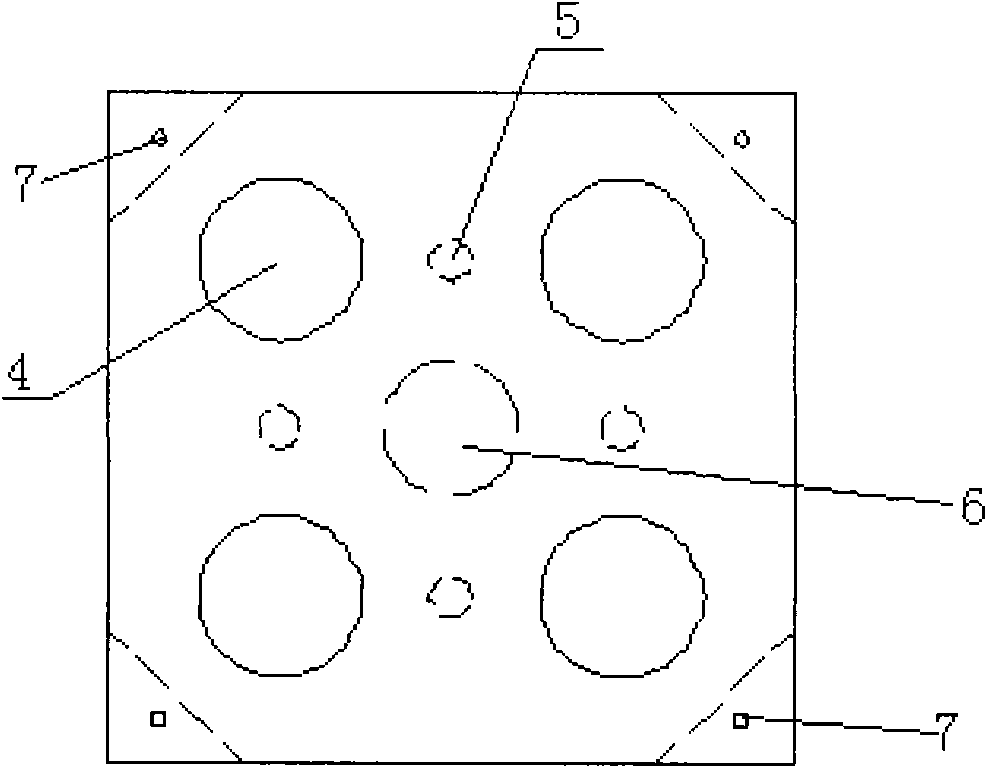

[0033] see figure 1 with figure 2, the present invention consists of a reinforced concrete column 1, a corrosion-resistant steel wire mesh 3, a plurality of suspended and fixed wind-shielding monomers 2 below, wind-shielding monomers 8 above, and wind-shielding monomers between 2 and 8. Wind and sand barriers. In the embodiment of the present invention, the reinforced concrete column 1 is 2.2m high, buried 0.5m underground, the upper end is 1.7m above the ground, the cross section is a square of 0.2×0.2m, and the distance between the concrete columns 1 is 1.6-2.1m; the suspended windshield The surface of the single body is square, with a side length of 0.5m; the thickness of the windshield single brick is 0.2m, the interlayer is hollow 0.1m, the diameter of the air inlet on the windward side is 8.0cm, and the four corners of the brick interlayer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com