Wet pile extension method for cast-in place pile

A technology of bored piles and wet method, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc. It can solve the problems of reduced pile quality, increased construction costs, and troublesome handling, and saves waste of manpower and material resources. The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

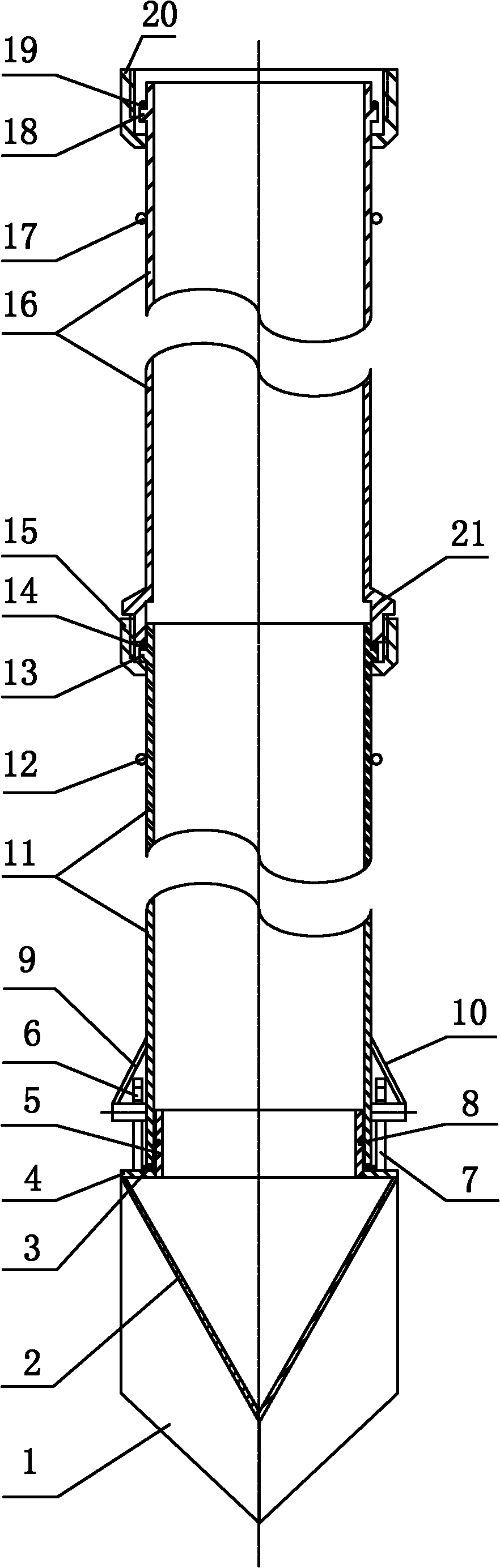

[0022] like figure 1 , Figure 7 Shown, a kind of wet pile connection method of bored pile, it comprises the steps:

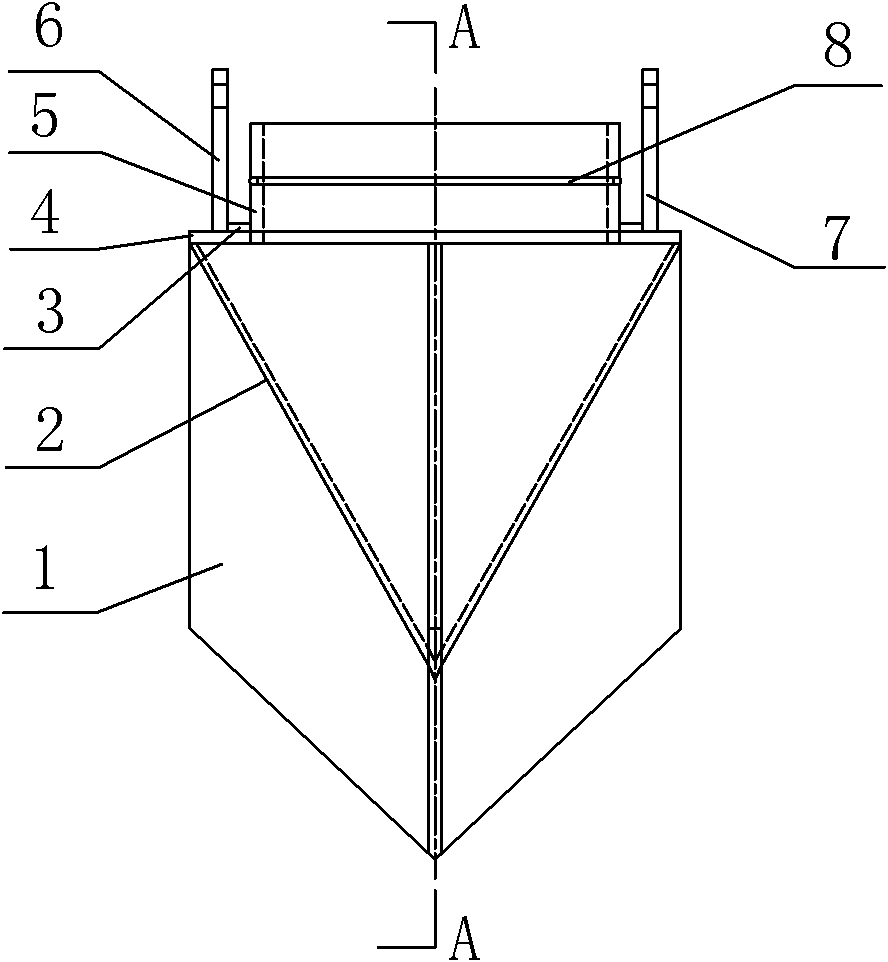

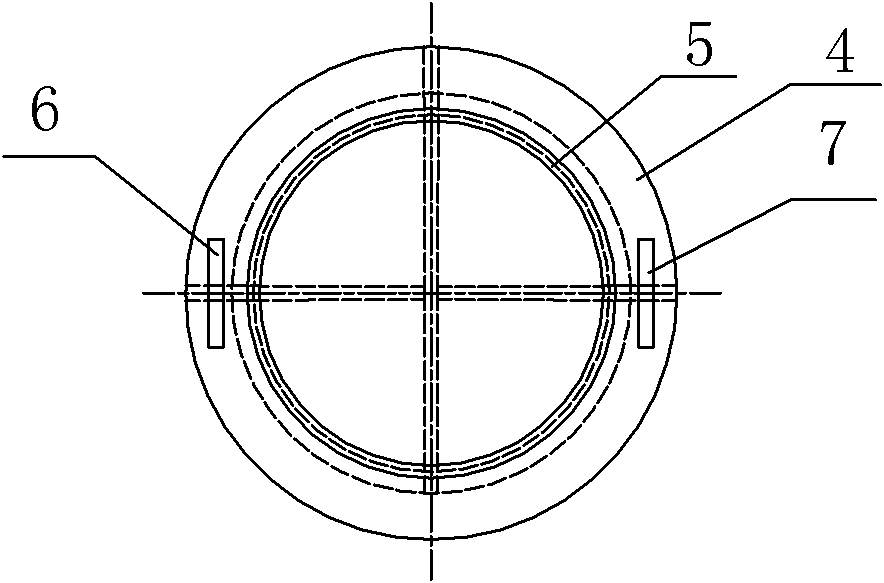

[0023] 1) Prepare the wet pile connection device for bored piles: the wet pile connection device for bored piles includes plugs 22 and conduits, and the conduits include bottom pipes 23 and branch pipes 24, and the number of pipes is 2-100 (the specific number depends on The depth of the broken pile position is determined); the sleeve pipe 5 of the plug is inserted into the lower end of the first steel pipe 11 of the bottom pipe, and the first steel pipe 11 of the bottom pipe is rotated counterclockwise, so that the left hook 6 of the plug is hooked on the bottom pipe. On the left hanging ring 9, the right hook 7 of the plug is hooked on the right hanging ring 10 of the bottom pipe, so that the plug is installed on the lower end of the bottom pipe;

[0024] 2) Measure and record the depth L1 of the broken pile position with a measuring rope, and pour concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com