Gas clamping valve

A card-type valve and gas technology, which is applied in the direction of lifting valve, valve detail, safety valve, etc., can solve the problems of difficult flow adjustment, difficult hand push buttons, endless bottles, etc., to achieve smooth hand feeling and good leak-proof effect , The effect of high gas utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

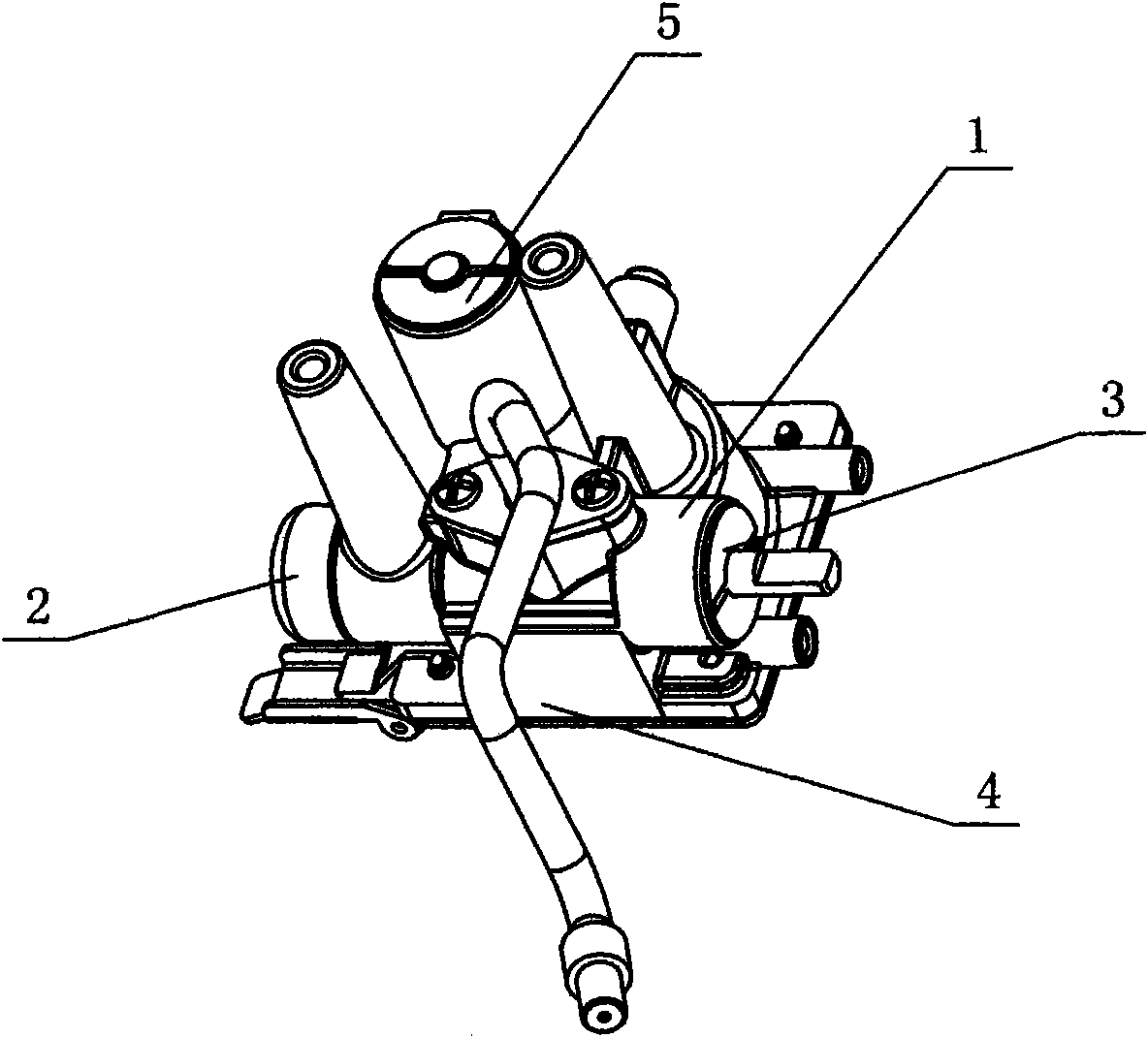

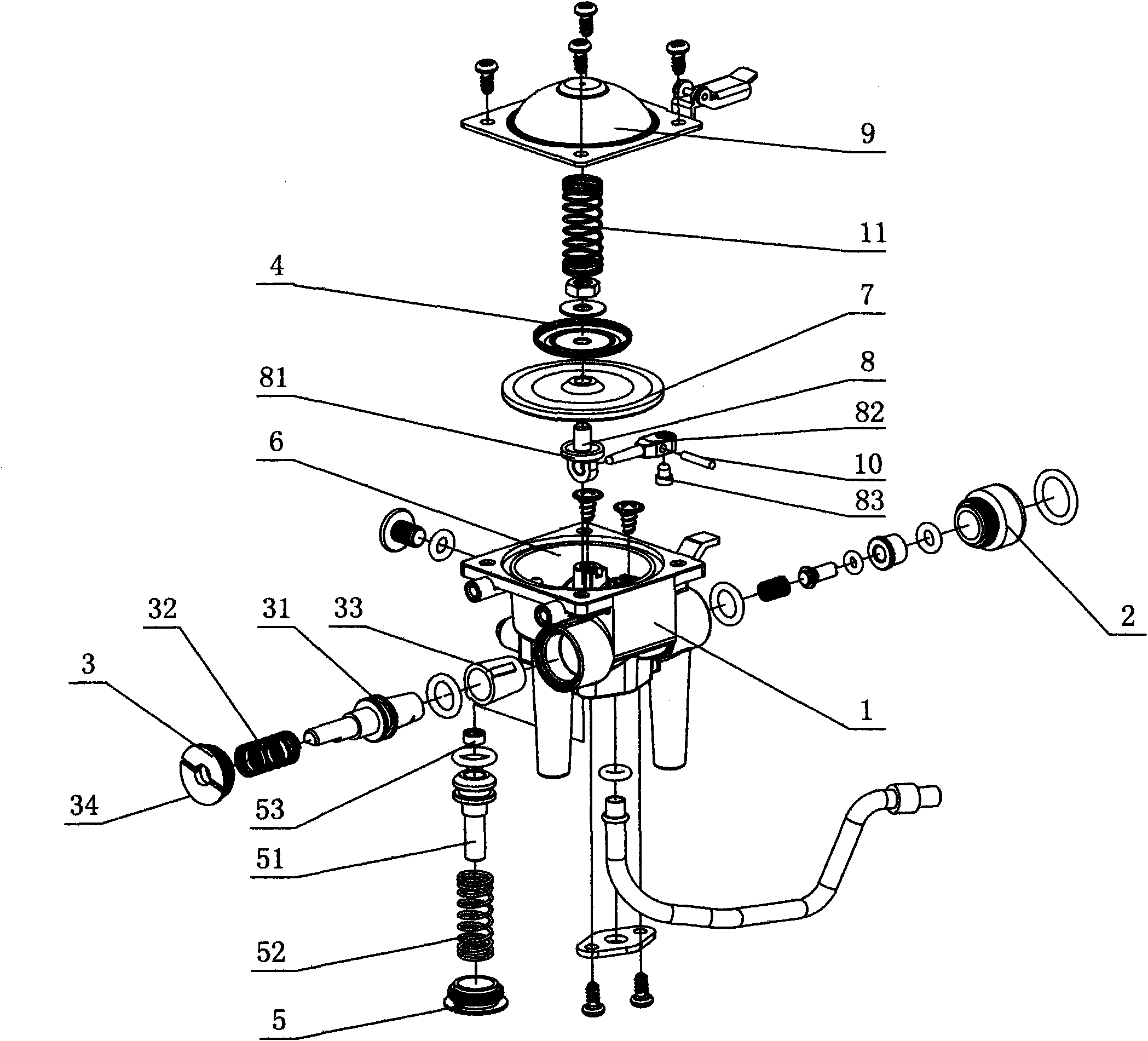

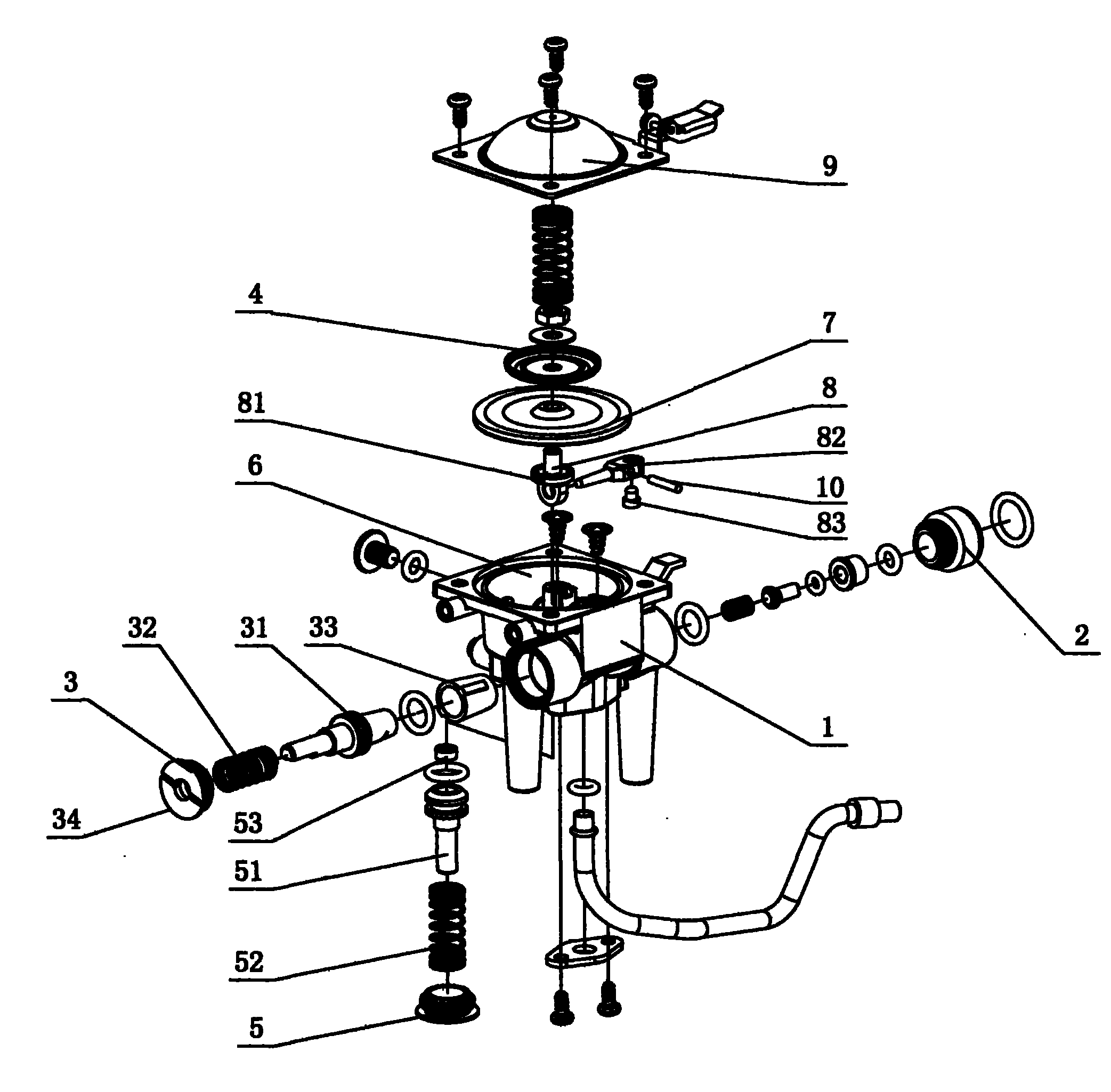

[0010] refer to figure 1 , figure 2 , a gas card valve according to an embodiment of the present invention includes a valve body 1 , an air inlet device 2 , an air outlet regulating device 3 , a pressure stabilizing device 4 and a safety device 5 . The valve body 1 is provided with a valve cavity 6 with a cavity structure, a soft diaphragm 7 is installed in the valve cavity 6, the lower part of the diaphragm 7 is supported by a diaphragm linkage mechanism 8, and a pressure spring 11 is installed on the upper part of the diaphragm 7 , and the valve cover 9 compresses the pressure spring 11 to seal and cover, the diaphragm 7 and the valve body 1 form a large cavity, and the pressure spring 11 is conducive to adjusting the pressure. The diaphragm connecting rod mechanism 8 is composed of a diaphragm connecting rod 81 fixedly installed in the center of the diaphragm 7 and an adjusting rod 82 for adjusting the diaphragm connecting rod 81. The adjusting rod 82 is equipped with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com