Unpressurized serial solar energy vacuum tube heat collector

A technology of vacuum tube collectors and vacuum tubes, which is applied to solar collectors, solar collectors using working fluids, solar thermal energy, etc., can solve the problems of high energy loss, high maintenance costs, and complicated operation, and achieve the goal of manufacturing And the effect of low installation cost, reduced maintenance cost, and controllable conduction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

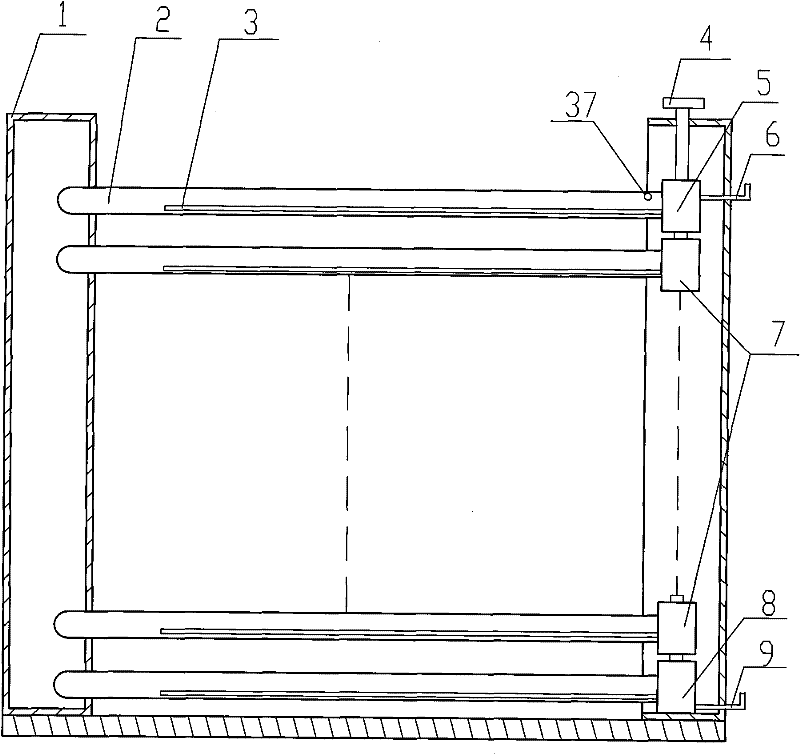

[0028] See attached figure 1 , the present invention uses the upper head 5, the middle head 7 and the lower head 8 to connect the vacuum tubes, so that the water system between the vacuum tubes forms a series connection, which greatly improves the effective conduction of the energy of the vacuum tube heat collector, and is suitable for For split solar water heaters. The vacuum tubes in the middle are connected through the middle head 7, which is a letter buckle connection, through the cooperation between the first head joint 14 on the middle head 7 and the first round hole 17, a water flow channel is formed, and The positioning protrusion 15 and the positioning circular hole 16 are positioned and coupled.

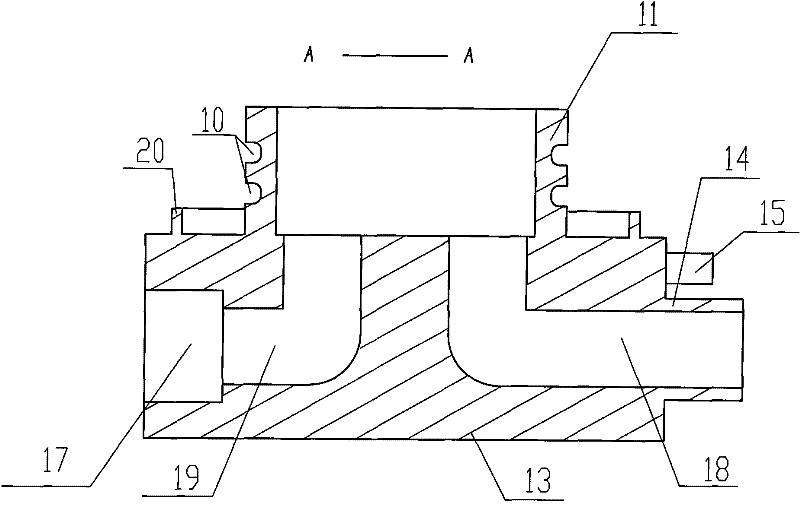

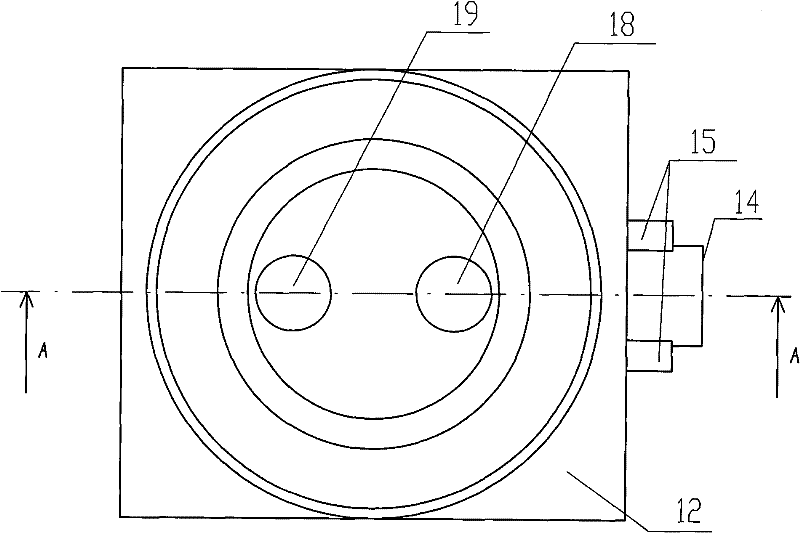

[0029] See attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 , the description of the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com