Graphite/carbon felt composite electrode for monocrystalline silicon growing furnace

A composite electrode and growth furnace technology, applied in the field of crystal growth equipment, can solve the problems of high energy consumption of graphite electrodes, achieve the effects of reducing power consumption, solving excessive energy, and avoiding movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

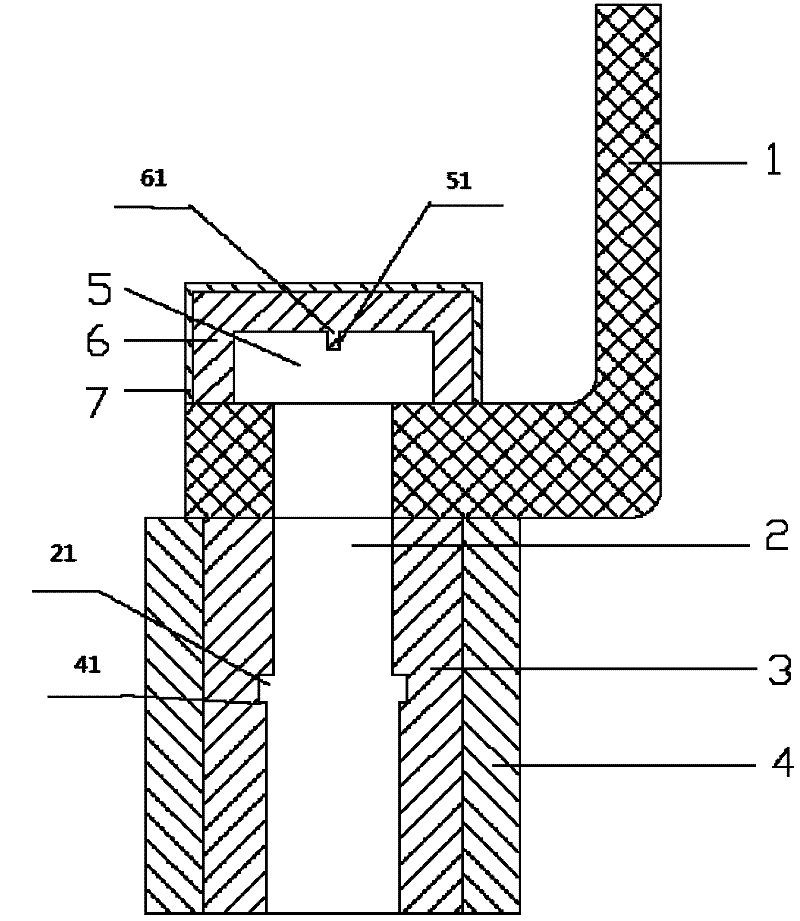

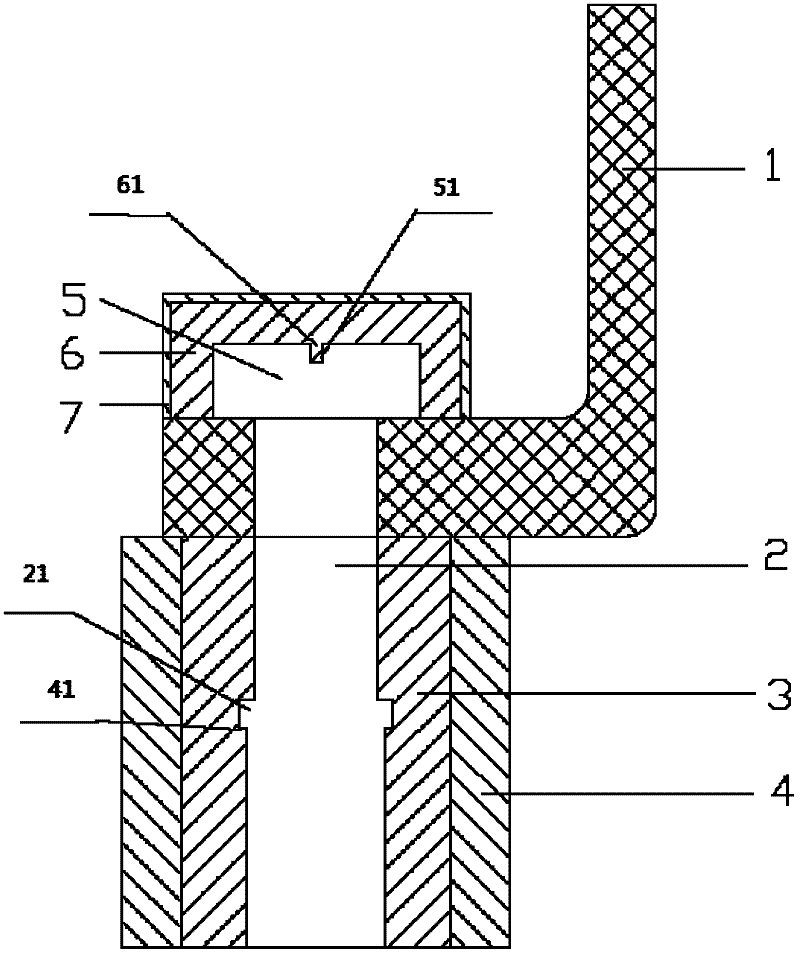

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] As shown in the figure, a graphite / carbon felt composite electrode for a single crystal silicon growth furnace includes a heater 1 and an electrode 2, the electrode 2 and the heater 1 are connected by bolts 5, and the electrode 2 is externally equipped with Graphite sheath 4, an electrode insulation layer 3 is fixed between the electrode 2 and the graphite sheath 4, and an electrode insulation layer 3 is fixed between the electrode 2 and the graphite sheath 4, which greatly increases the temperature of the crystal furnace. The thermal resistance between the inside and the electrode reduces the power consumption, and its energy-saving effect can reach more than 10kW, which solves the problem of excessive energy loss of the heater electrode in the crystal furnace. In order to make the connection between the electrode and the electrode insulation layer more firm, a flan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com