Coupling packaging structure and method of single mode fiber and silicon-based photo-electronic chip end face

An optoelectronic chip, single-mode fiber technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of large surface area, high energy loss, huge loss, etc., to achieve large surface area, improve efficiency, and improve coupling redundancy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

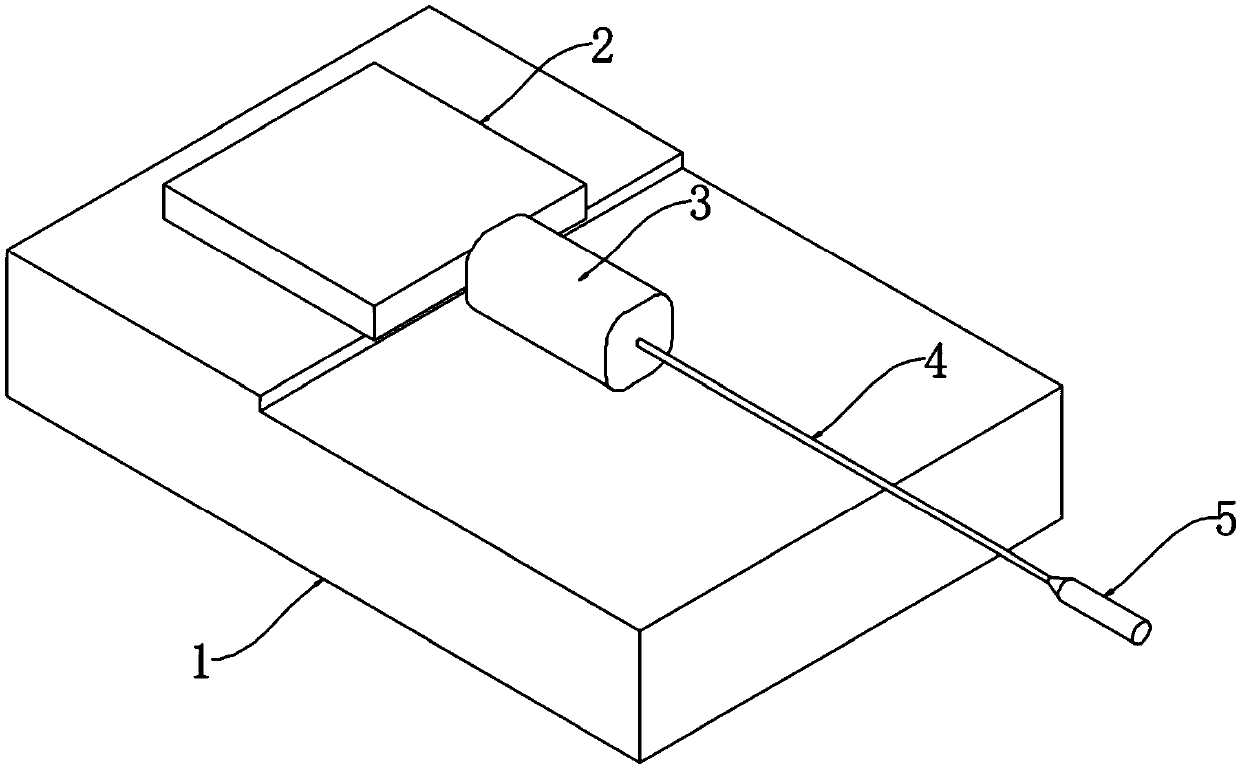

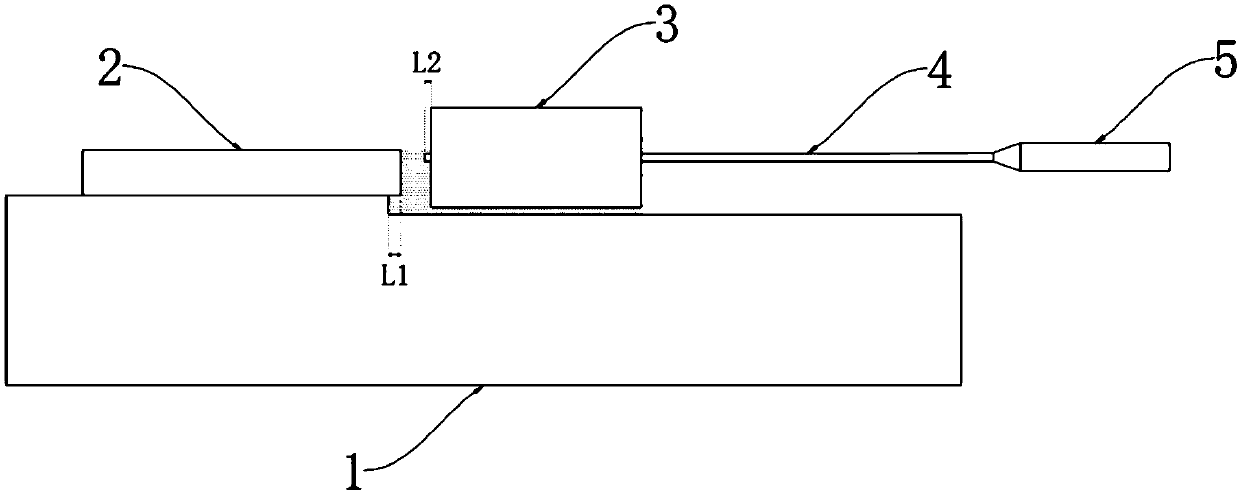

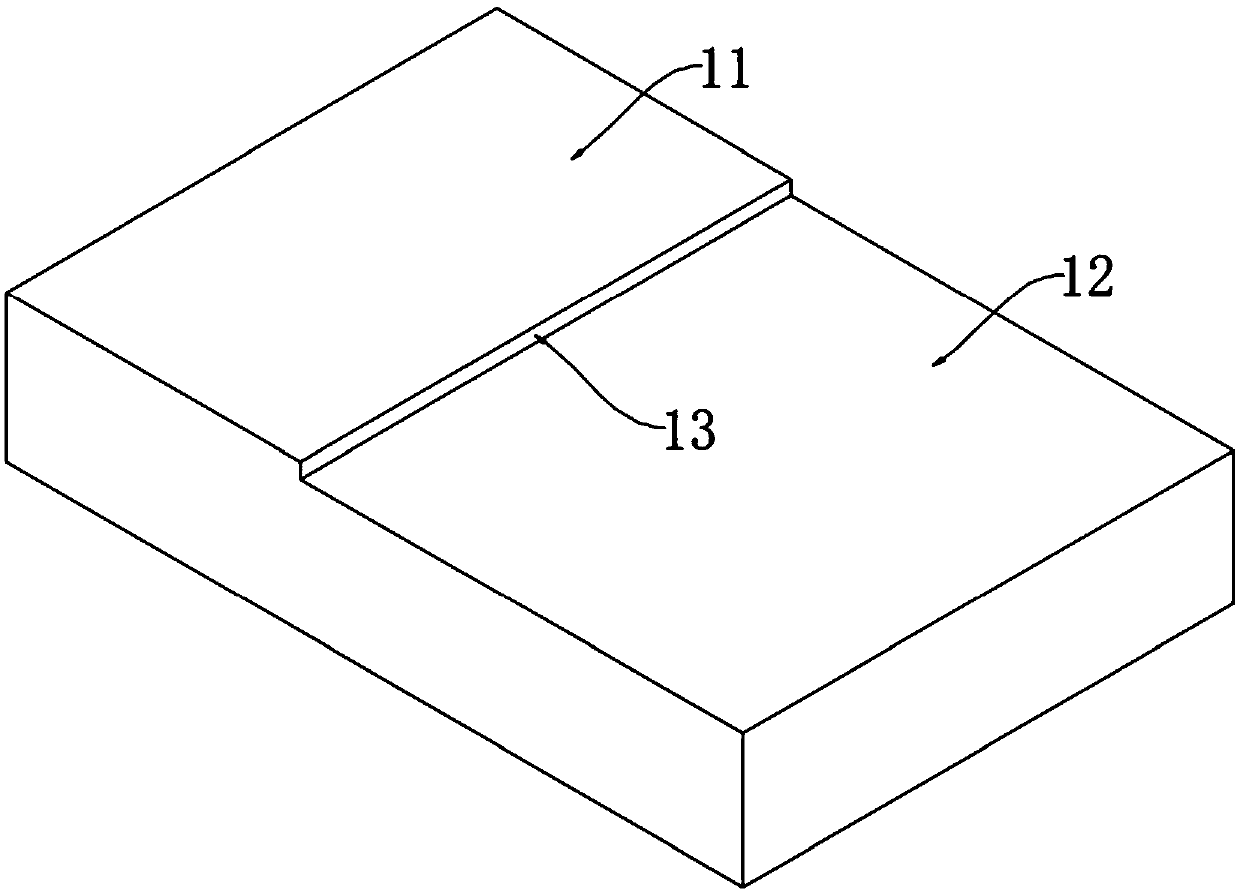

[0047] Such as Figures 1 to 5As shown, this embodiment discloses a coupling packaging structure of a single-mode optical fiber and an end face of a silicon-based optoelectronic chip. The coupling packaging structure includes a base plate 1, a silicon-based optoelectronic chip 2, an optical fiber capillary 3, a high numerical aperture optical fiber 4 and a single-mode optical fiber 5 It should be understood that the numerical aperture (NA) range of the high numerical aperture optical fiber 4 involved in the present invention is 0.28~0.41, and the high numerical aperture optical fiber 4 can select UHNA1 (NA: 0.28, core diameter 2.5 μ m:) or UHNA3 (NA : 0.35, core diameter: 1.8 μm) or UHNA4 (NA: 0.35, core diameter: 2.2 μm) or UHNA7 (NA: 0.41, core diameter: 2.4 μm); in this embodiment, the selected high numerical aperture fiber The model of 4 is UHNA7, and the high numerical aperture optical fiber 4 has two ends. In this embodiment, the two ends of the high numerical aperture o...

Embodiment 2

[0054] Based on the same inventive concept as Embodiment 1, this embodiment discloses a coupling and packaging method for a single-mode optical fiber and the end face of a silicon-based optoelectronic chip, based on an optical fiber with a special structural design (an optical fiber formed after fusion of a high numerical aperture optical fiber and a single-mode optical fiber ), through end-face coupling between one end of the high numerical aperture optical fiber and the silicon-based optoelectronic chip, thereby providing a highly stable packaging method for the single-mode fiber and the end face of the silicon-based optoelectronic chip, specifically, as Figure 6 As shown, the coupling and packaging method includes the following steps.

[0055] Step 1, fusion splicing and fiber capillary setting steps: fusion splicing end 41 of high numerical aperture optical fiber 4 and one end of single mode optical fiber 5, and after the two are fused, a gradual tapered shape is formed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com