High-temperature directly buried pipeline heat preservation structure

A technology of pipeline thermal insulation and direct burial, which is applied in pipeline protection, thermal insulation, pipeline anti-corrosion/anti-rust protection, etc. The effect of high temperature, solving excessive energy loss and saving capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

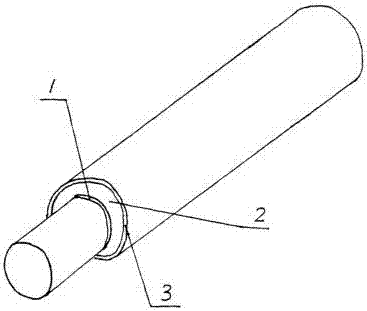

[0009] The present invention provides a kind of heat preservation mechanism of high-temperature directly buried pipeline as shown in Figure 1 and comprises: anticorrosion layer 1, heat preservation layer 2, waterproof layer 3 are formed, and the shape of described pipeline is tubular, and wherein middle layer is moisturizing layer 2, is made of Composed of hydrophobic composite silicate moisture-retaining material, the outer surface used to be a waterproof layer 3, which is made of fiber cloth coated with waterproof paint or fiberglass resin structure, and the inner surface layer is a cyanide anti-corrosion layer 1.

[0010] Compared with the prior art, the technical effect and advantages of the present invention are: high heat-resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com