On-line high-pressure tightness testing method for brake caliper

A high-pressure sealing and testing method technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, can solve the problems of difficult to realize online detection of brake calipers and low detection efficiency rate, etc. Achieve the effects of ensuring reliability, realizing online detection, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

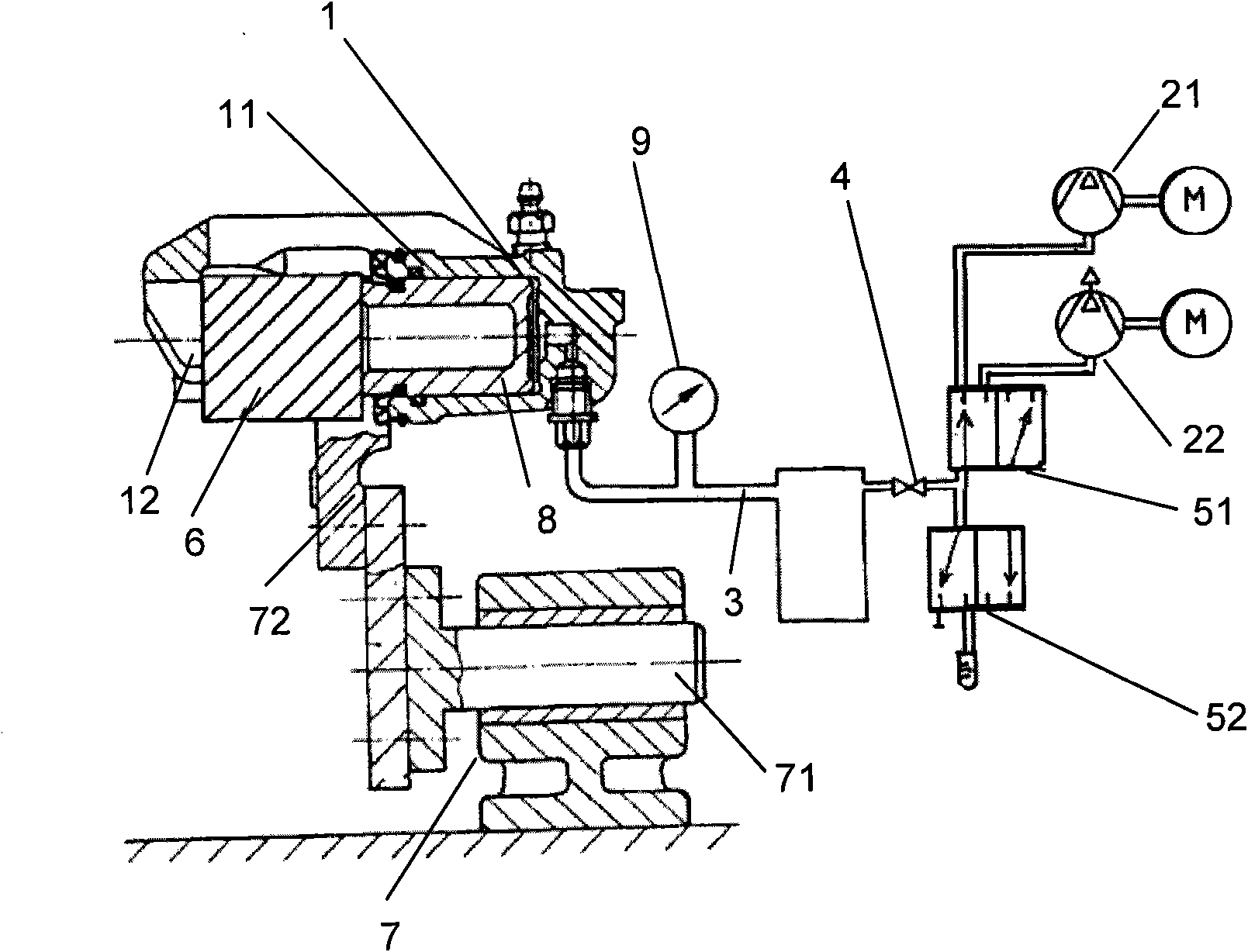

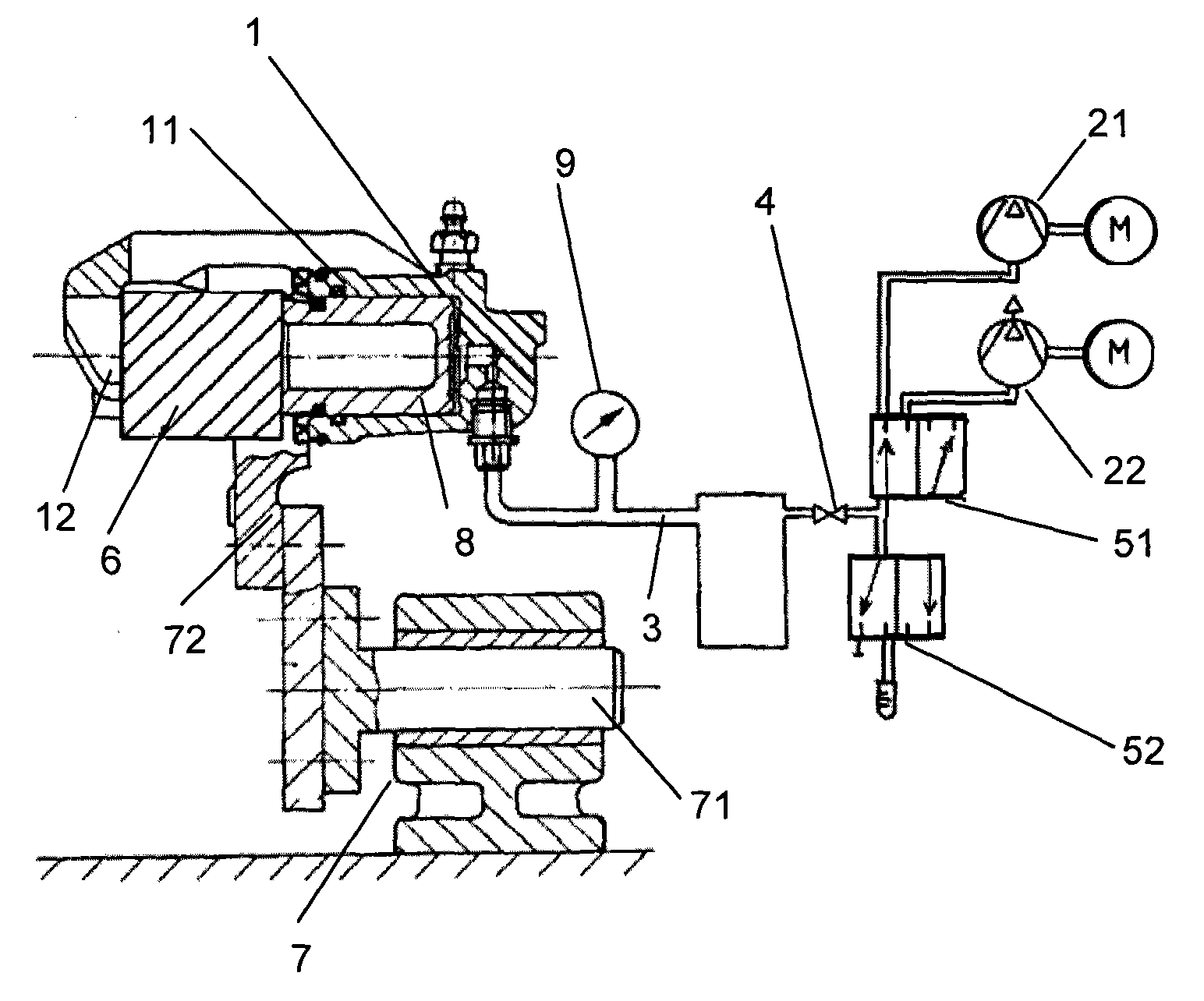

[0012] The brake caliper online high-pressure sealing test method of the present invention can be combined with figure 1 Further explanation is as follows:

[0013] Firstly, the caliper body 1 of the brake caliper is connected with the compressed air source by the pipeline 3 , and a valve 4 is set on the pipeline 3 . In one embodiment of the present invention, the gas source includes a first gas source 21 and a second gas source 22 . In order to facilitate the switch connection between the first air source 21 and the second air source 21 for the caliper body 1 , a first switching valve 51 is further provided between the valve 4 and the air source. In addition, a second switching valve 52 for discharging compressed air is also provided on the pipeline 3 .

[0014] Then, a brake disc simulation test piece 6 is placed between the piston cylinder body 11 of the caliper body 1 and the outer friction plate seat 12 . The brake disc simulation test piece 6 is connected to a push pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap