High-performance fiber drying detection testing machine

A high-performance fiber and testing machine technology, applied in the preparation of test samples, etc., can solve the problems of unguaranteed fiber quality, long debugging cycle, inability to track and detect the internal structure of the fiber, and achieve convenient operation and reasonable structure. , Overcome the effect of long debugging cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

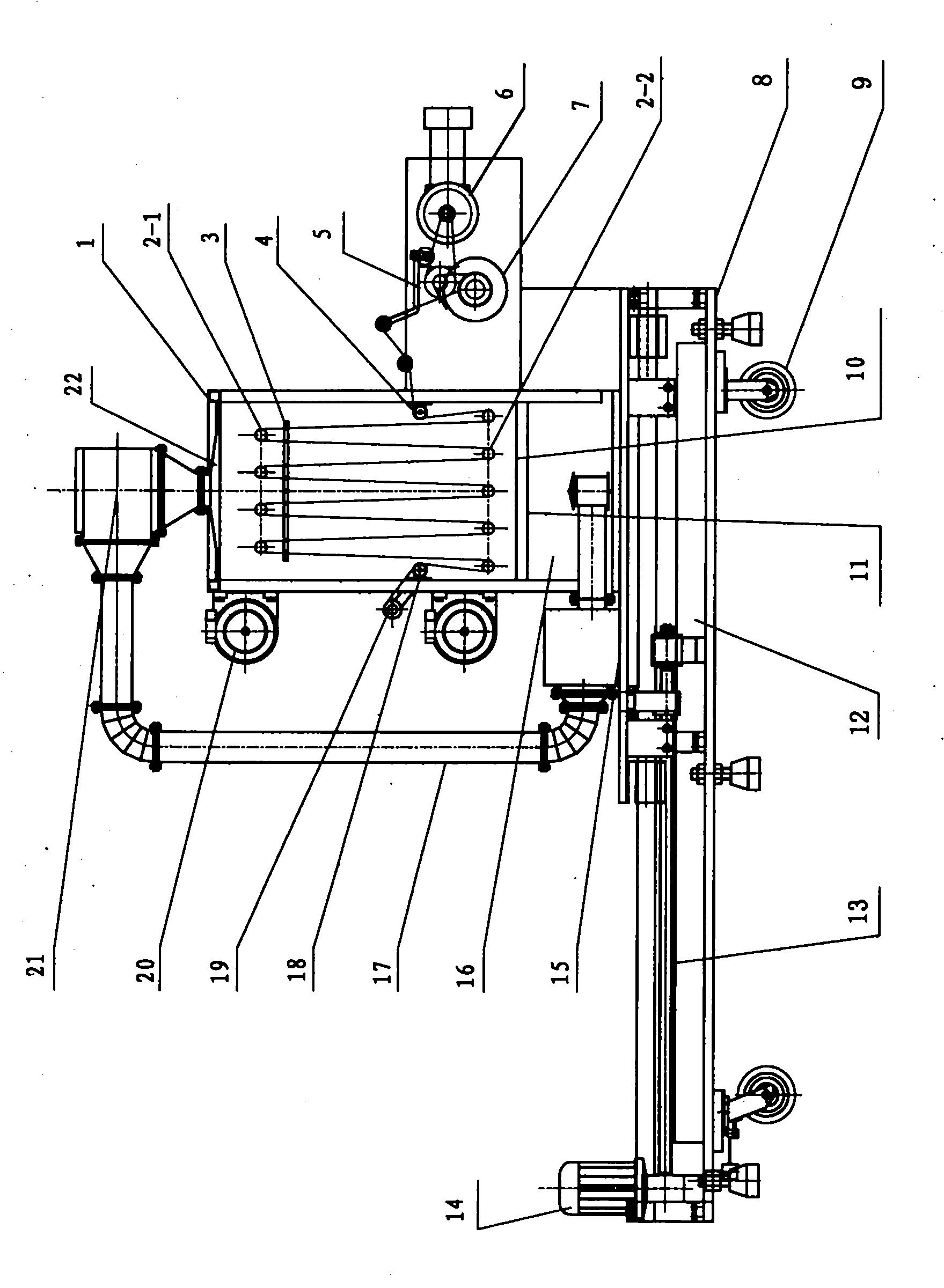

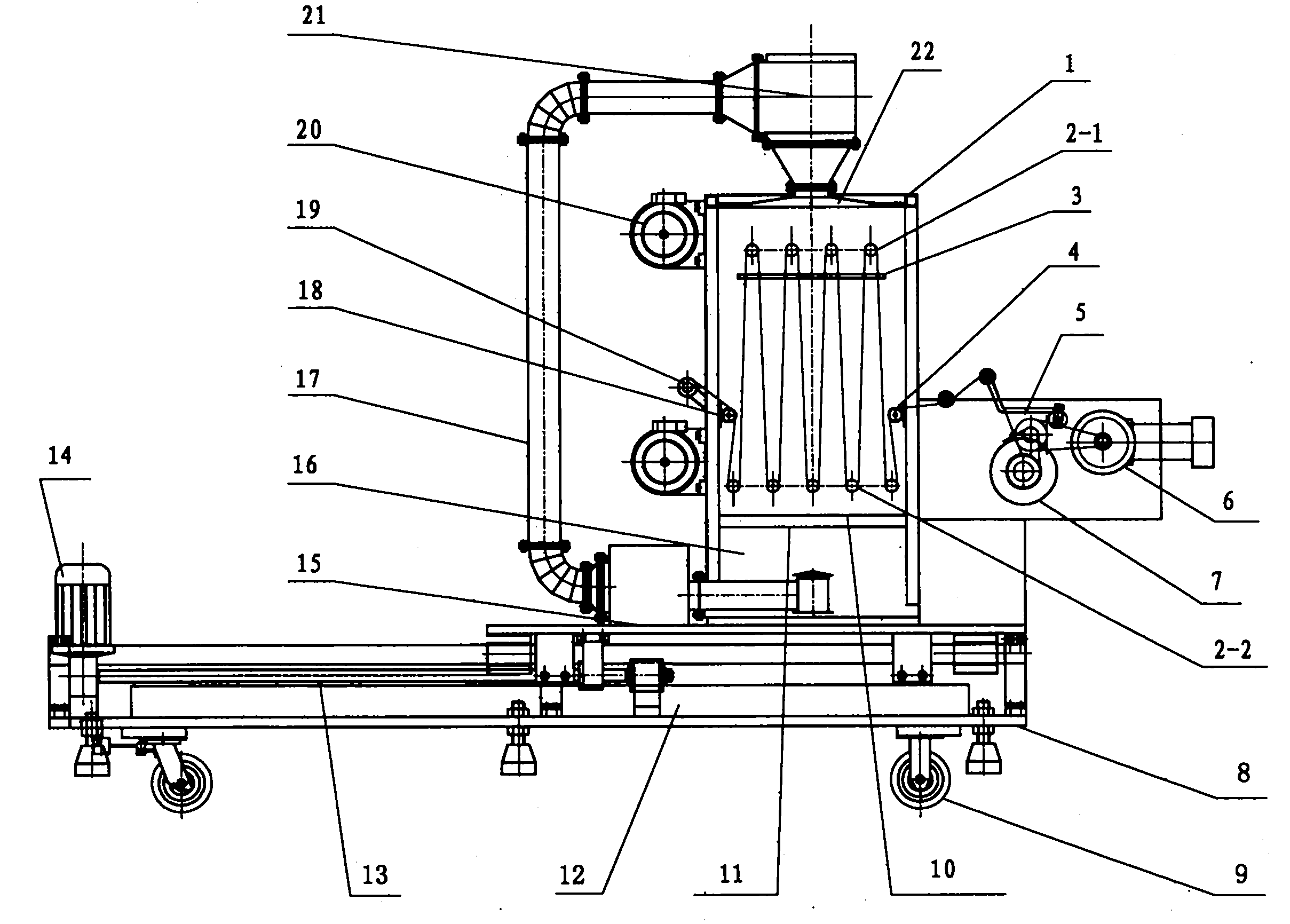

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] The high-performance fiber drying testing machine of the present invention includes a machine base, a drying mechanism, a winding mechanism and a translation mechanism;

[0017] The drying mechanism is used to heat and dry the fiber tow, including a drying box 1, a heating box 15, a support roller, a return air pipe 17, a fan 21 and a pressure equalizing box 16; The upper four and the lower five rows are provided with upper wire rollers 2-1 and lower wire rollers 2-2, and the upper and lower rows of wire rollers 2-1 and 2-2 are each driven by a synchronous motor 20; the drying box 1 The middle part of both sides is provided with a wire inlet and a wire outlet, and a wire inlet roller 18 and a wire outlet roller 4 are respectively provided at the inner wall sides of the drying cabinet 1 corresponding to the wire inlet and the wire outlet; The fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com