Manufacturing method of spiral bracket and spiral bracket

A helical and coating technology, which is applied in the manufacture of helical stents and the field of helical stents, can solve the problems of center deviation and coating layer center deviation, etc., and achieve the effects of prolonging life, high dielectric strength and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

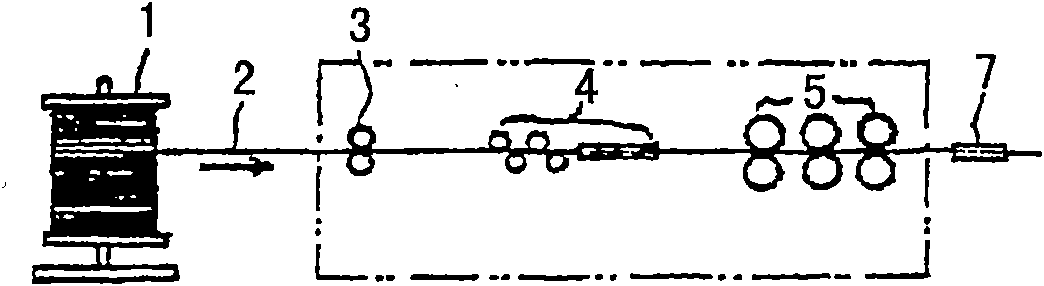

[0036] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a schematic diagram of a device for feeding the tough metal core wire 2 wound on a spool forward (to the right in the drawing).

[0037] In this figure, reference numerals 5, 5... denote feed rollers, which are respectively arranged in a pair up and down, and are driven by a driving device not shown, and feed the metal wire 2 between grooves provided around the rollers. Here, reference numeral 3 is a guide roll, and reference numeral 4 is a straightening roll.

[0038] And, when the feed rollers 5, 5, ... are rotated, the metal core wire 2 can be fed forward, that is, toward the direction of the guide pipe 7.

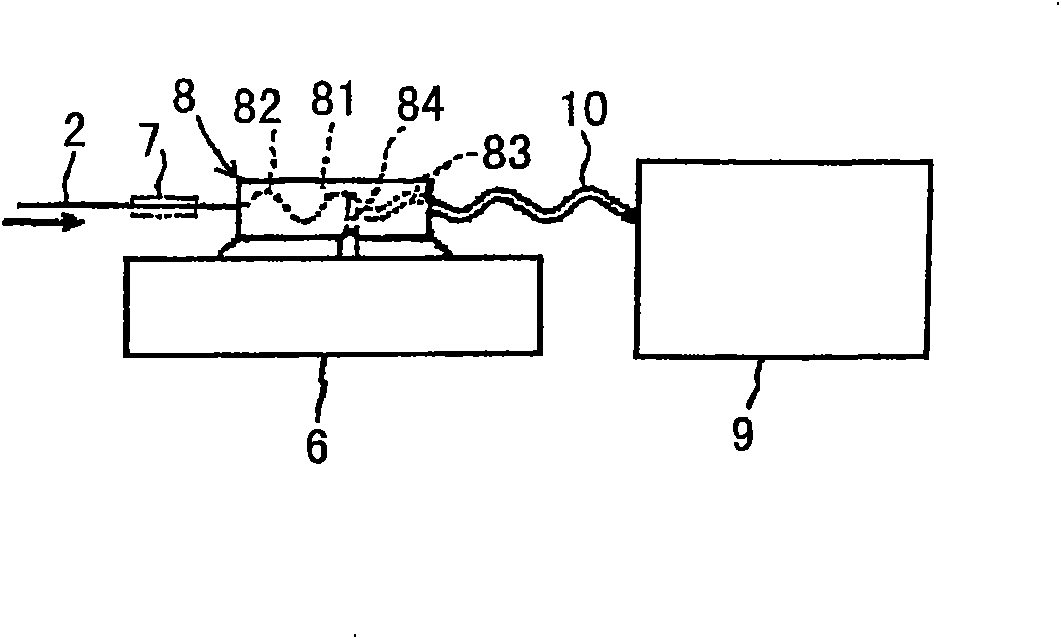

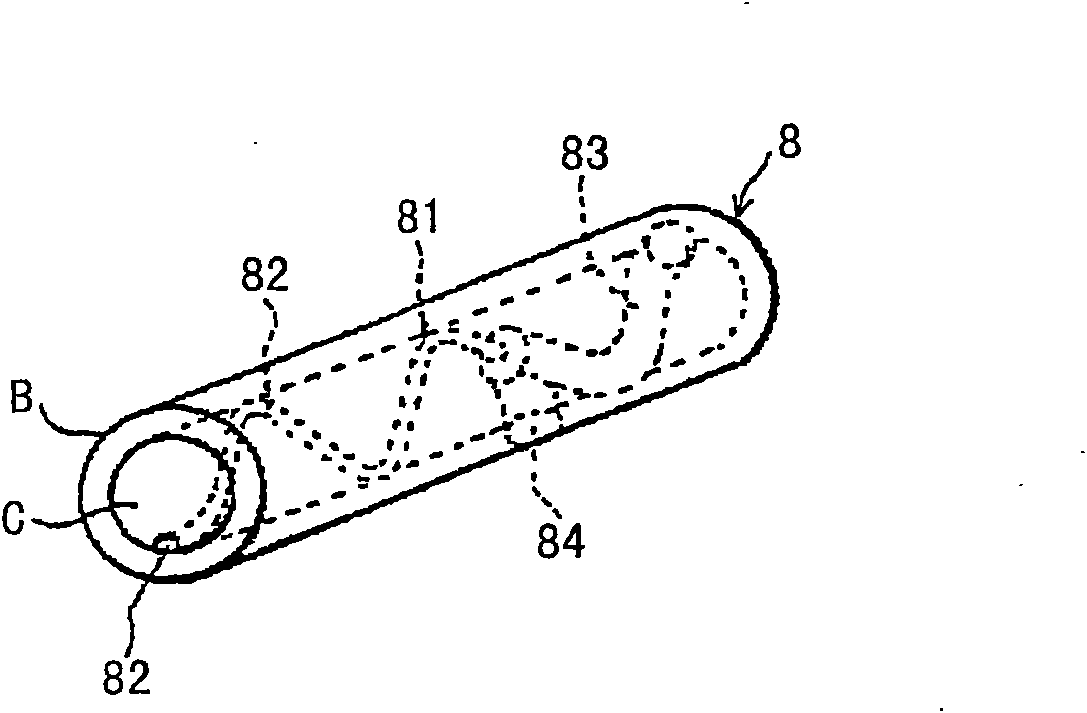

[0039] Next, the metal core wire 2 fed by the above process is introduced into the mold 8 provided with the long helical two-stage hole, and is forced to pass through the mold 8 to form the long helical metal wire, and the long helical wire is made of a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com