Ultraviolet and infrared double-color detector and manufacturing method thereof

A two-color detector and infrared technology, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as inability to detect ultraviolet radiation at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

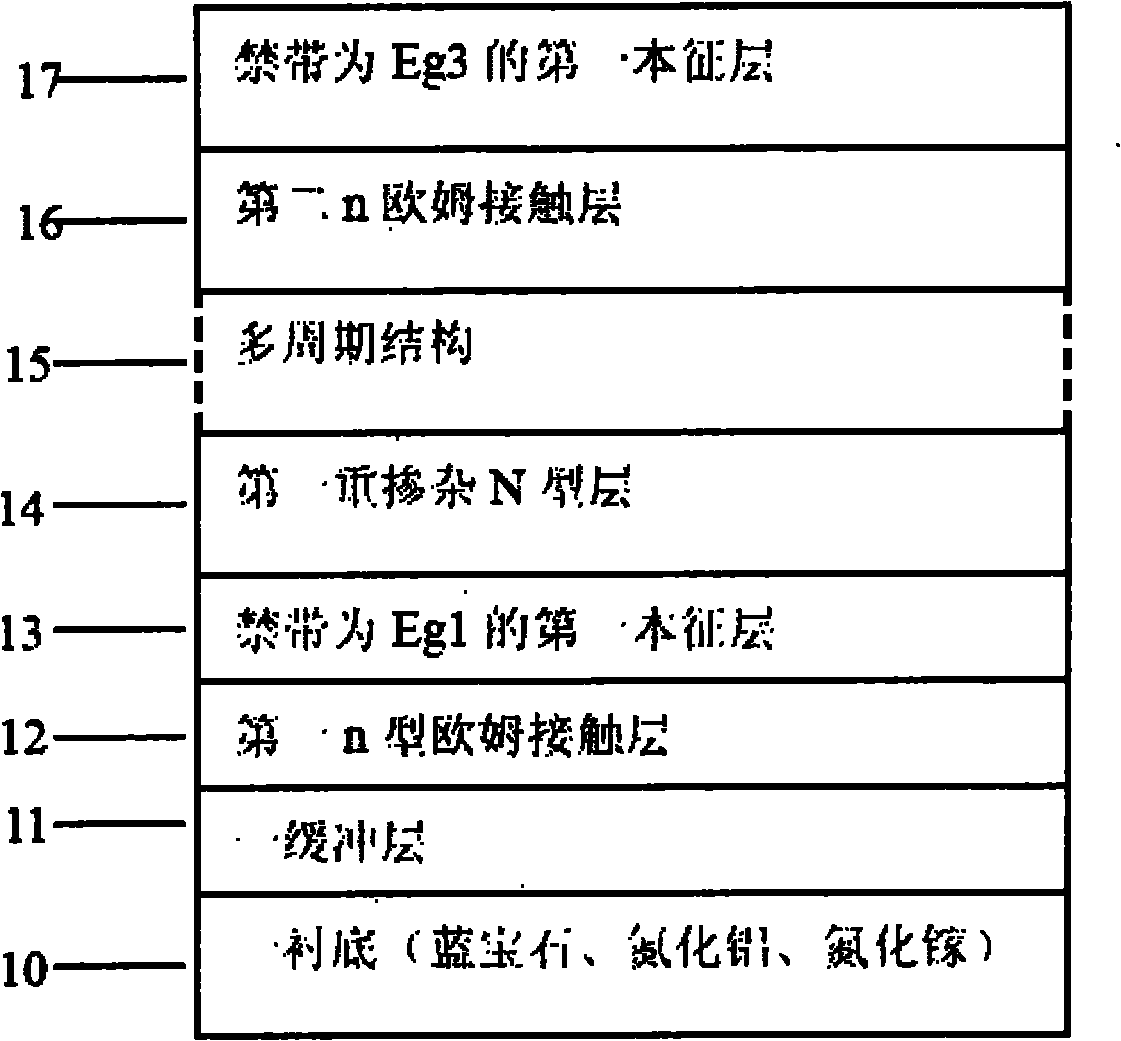

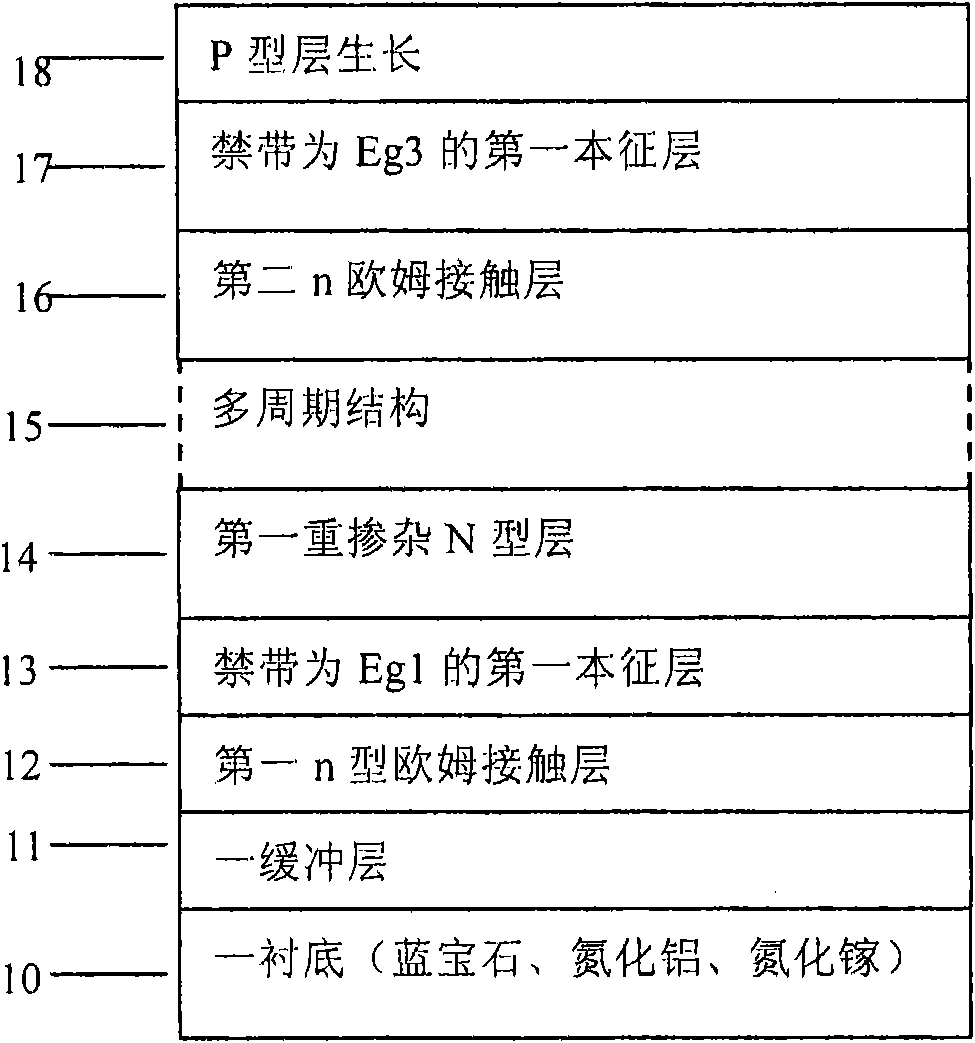

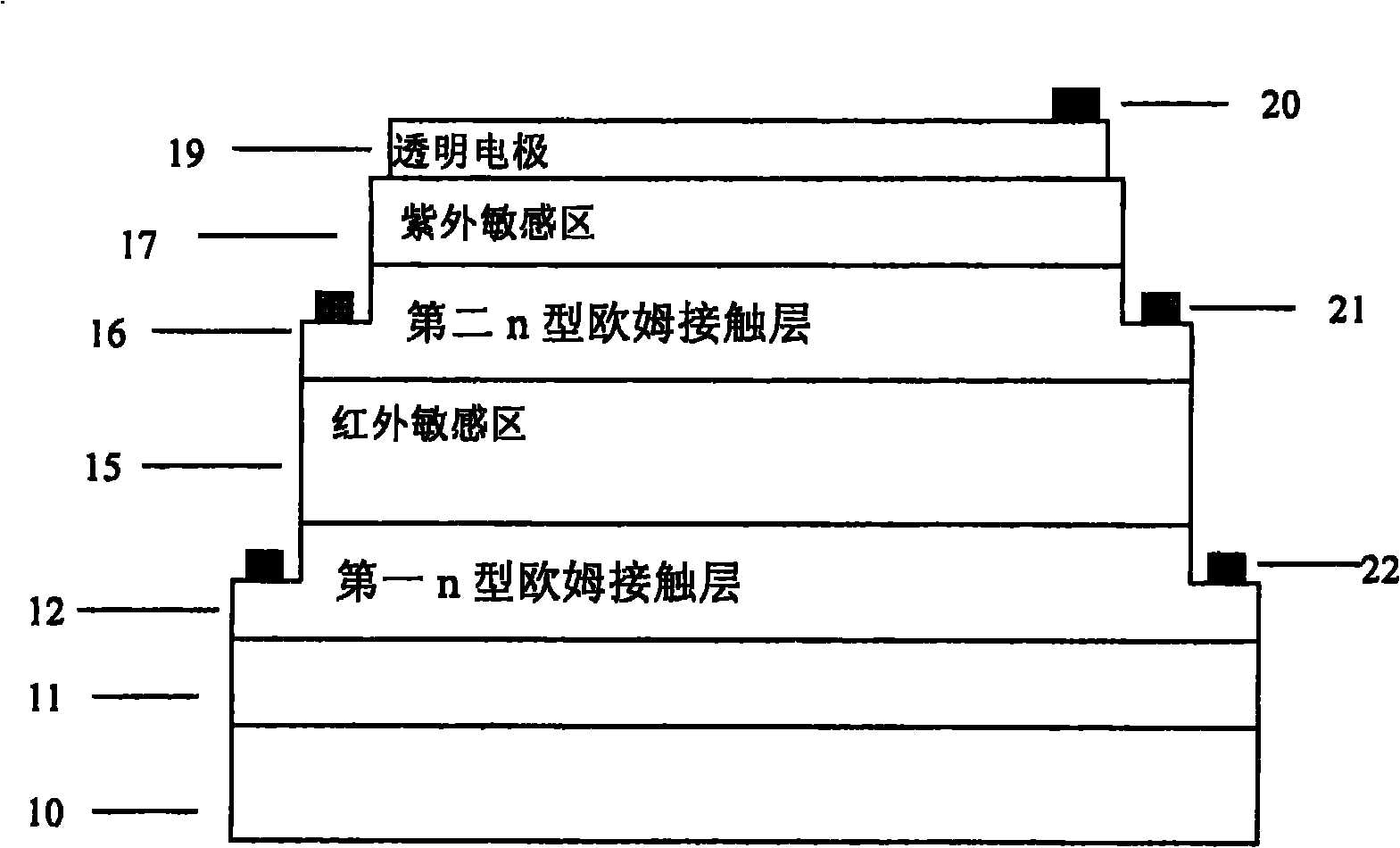

[0089] Taking the Schottky barrier-HEIWIP structure as an example for the infrared-ultraviolet dual-color detector, the structure is to sequentially grow a thin layer of AlN or GaN buffer layer 11 on the sapphire substrate 10 using MOCVD or MBE equipment, with a thickness of 0.02 to 0.1 μm, grow the first n-type ohmic contact layer 12 on the buffer layer 11: n + - AlGaN or GaN, with a thickness of 1.5-5.0 μm and a doping concentration n of 5×10 17 cm -3 ~5×10 19 cm -3 scope. Intrinsic layer 13 / heavily doped layer 14 is sequentially grown on the first n-type ohmic contact layer 12: i-AlGaN / n + -GaN or i-Al x Ga 1-x N / n + -Al y Ga 1-y N(x>y), alternate growth of intrinsic layer l3 / heavily doped layer 14 to form a multi-period structure 15, wherein, i-AlGaN or i-Al x Ga 1-x The electron carrier concentration of N is 5×10 14 ~5×10 17 cm -3 , with a thickness of 0.02-0.4 μm; n + -GaN or n + -Al y Ga 1-y The concentration of N is at 5×10 17 cm -3 ~5×10 19 cm -3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com