Chemical reactor with plate type heat exchange unit

A heat exchange unit and chemical reactor technology, applied in the field of chemical reactors, can solve the problems of impossibility cannot exceed a certain limit, cannot reduce welding points, and is not easy to apply, etc., and achieves high mechanical strength and large exchange surface. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

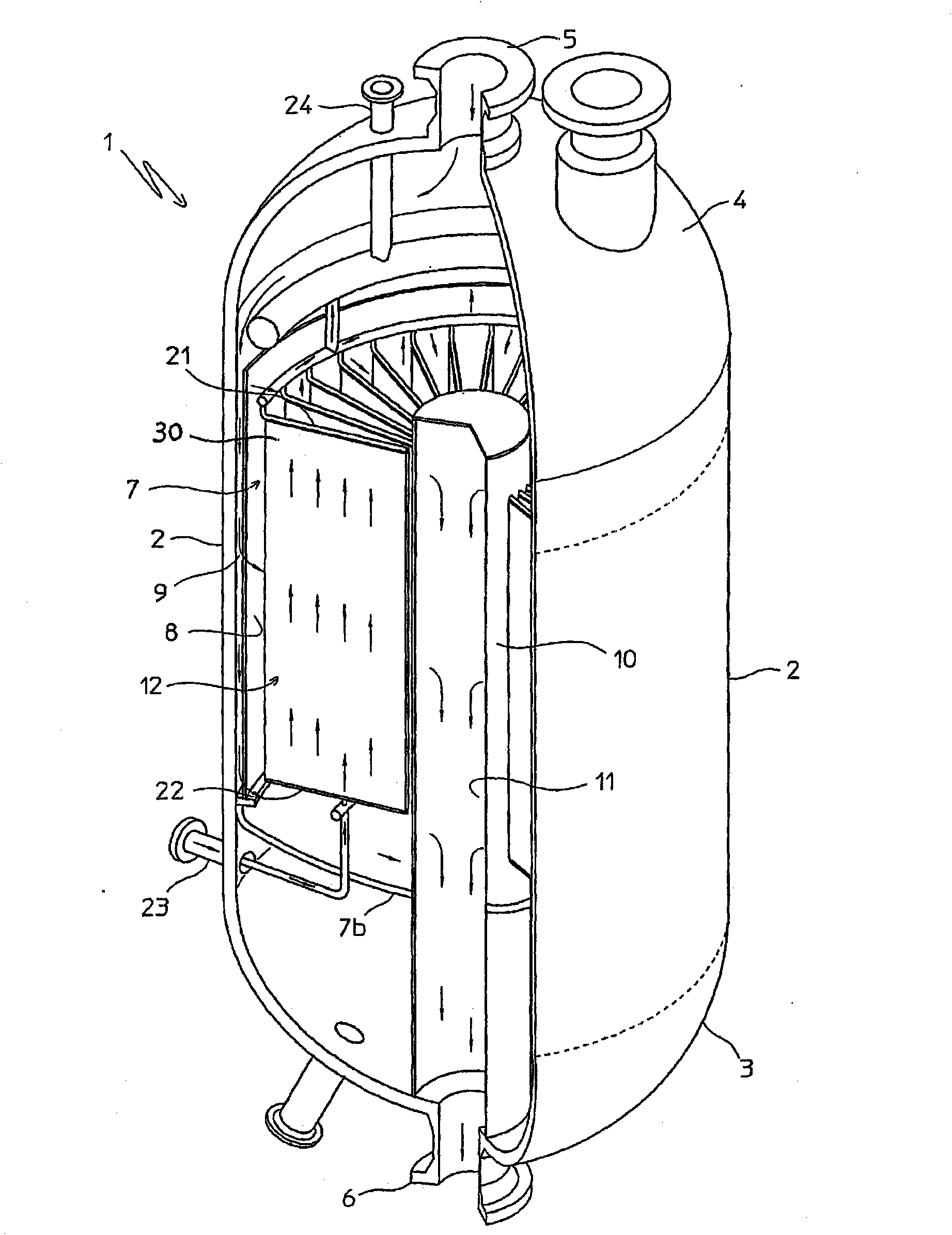

[0039] refer to figure 1 , the shown isothermal chemical reactor 1 comprises a cylindrical housing 2 with a vertical axis, a lower end 3 and an upper end 4 equipped with flanges 5 for the inlet of the reagents and 6 for the outlet of the reaction products, respectively.

[0040] figure 1 An example of is a catalytic reactor, for example, for the synthesis of methanol, which comprises a catalytic rack 7 which is substantially cylindrical and ring-shaped. The catalytic shelf 7 is mainly composed of an outer cylindrical wall 8, an inner cylindrical wall 10 and an annular bottom 7b. The outer wall 8 with the cover 2 defines a gap 9 of reduced width. Rack 7 is intended to contain a number of suitable catalysts (not shown).

[0041] Said outer wall 8 and said inner wall 10 are perforated so as to allow the passage of reagent gases from the gap 9 into the shelf 7 and of the gaseous reaction products from the shelf 7 to the central duct 11 which constitutes said reaction products ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com