Hot scarfer

A technology of flame cleaning and supporting blocks, which is applied in the direction of gas flame welding equipment, workpiece surface treatment equipment, metal rolling, etc., and can solve the unrealistic, easy deformation of the end of the flame cleaning unit, and the large manpower required for manufacturing, handling, and setting And cost and other issues, to achieve the effect of preventing the leakage of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described below.

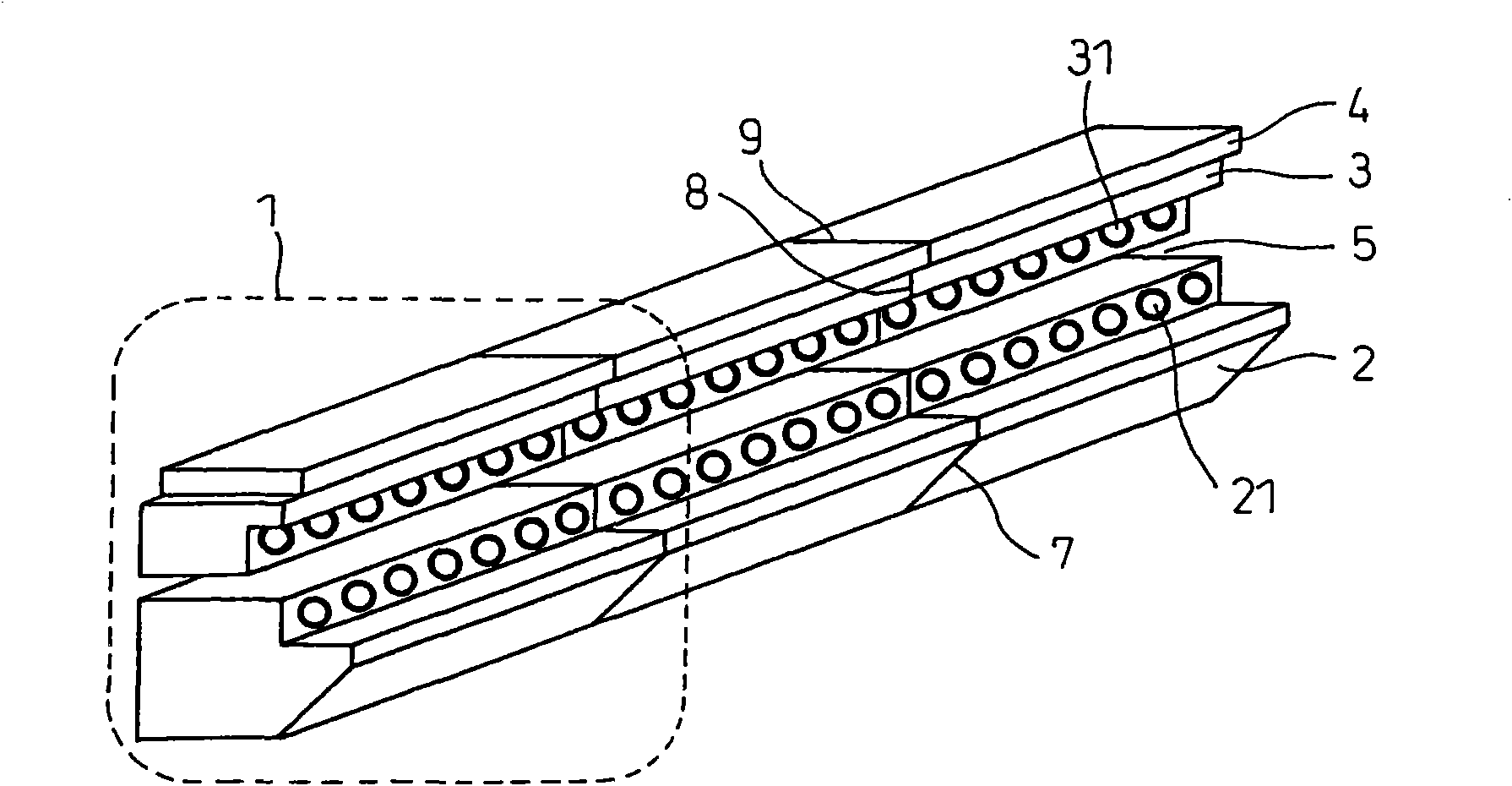

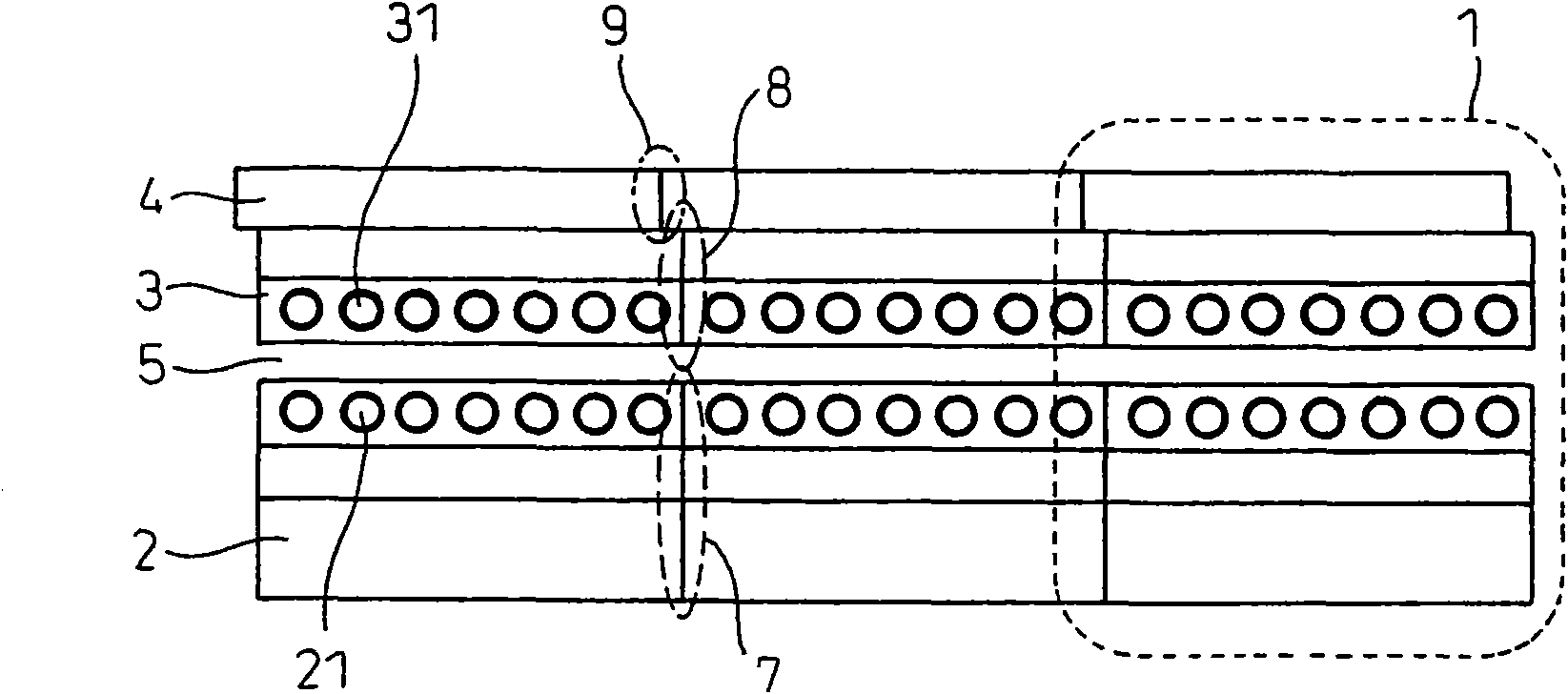

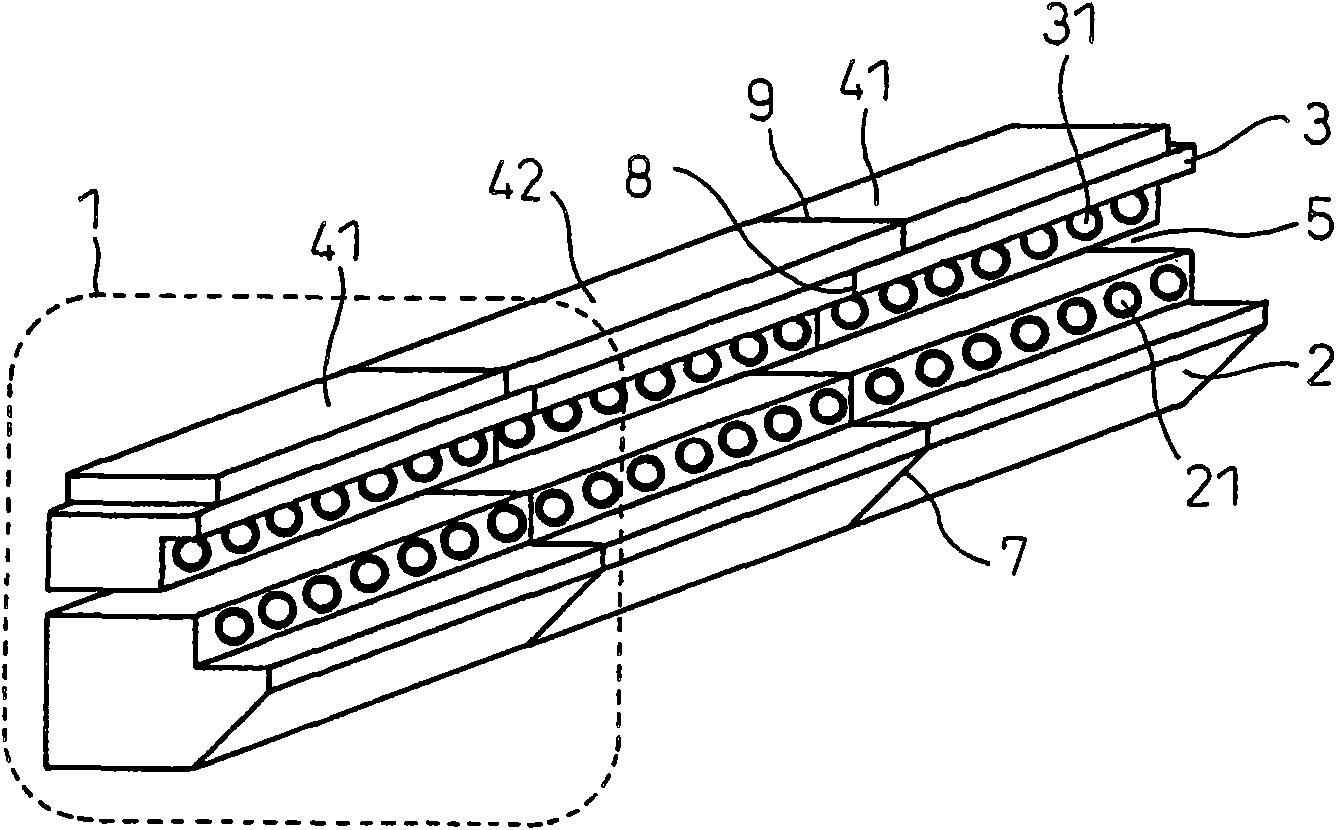

[0029] figure 1 , 2 It is a figure which shows the flame cleaning machine (flame cleaning unit / slab lower side) of the hot-rolled material which concerns on the 1st Embodiment of this invention. Each flame cleaning unit 1 is made of an upper support block 2, a lower support block 3 on the lower side of the upper support block and a base plate 4 fixed on the lower support block 3 with a fixture.

[0030] The upper support block 2 and the lower support block 3 inject combustible gas from a plurality of combustible gas injection ports 21, 31, and the combustible gas is burned by oxygen supplied from the oxygen passage 5 between the upper support block 2 and the lower support block 3 , thereby forming high-temperature combustion gases. Repairs for flame cleaning the surface of the slab to remove surface defects can be performed using the high-temperature combustion gas formed.

[0031] In the hot-rolled pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com