Fuel cell system and method of operating the same

A fuel cell system, fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

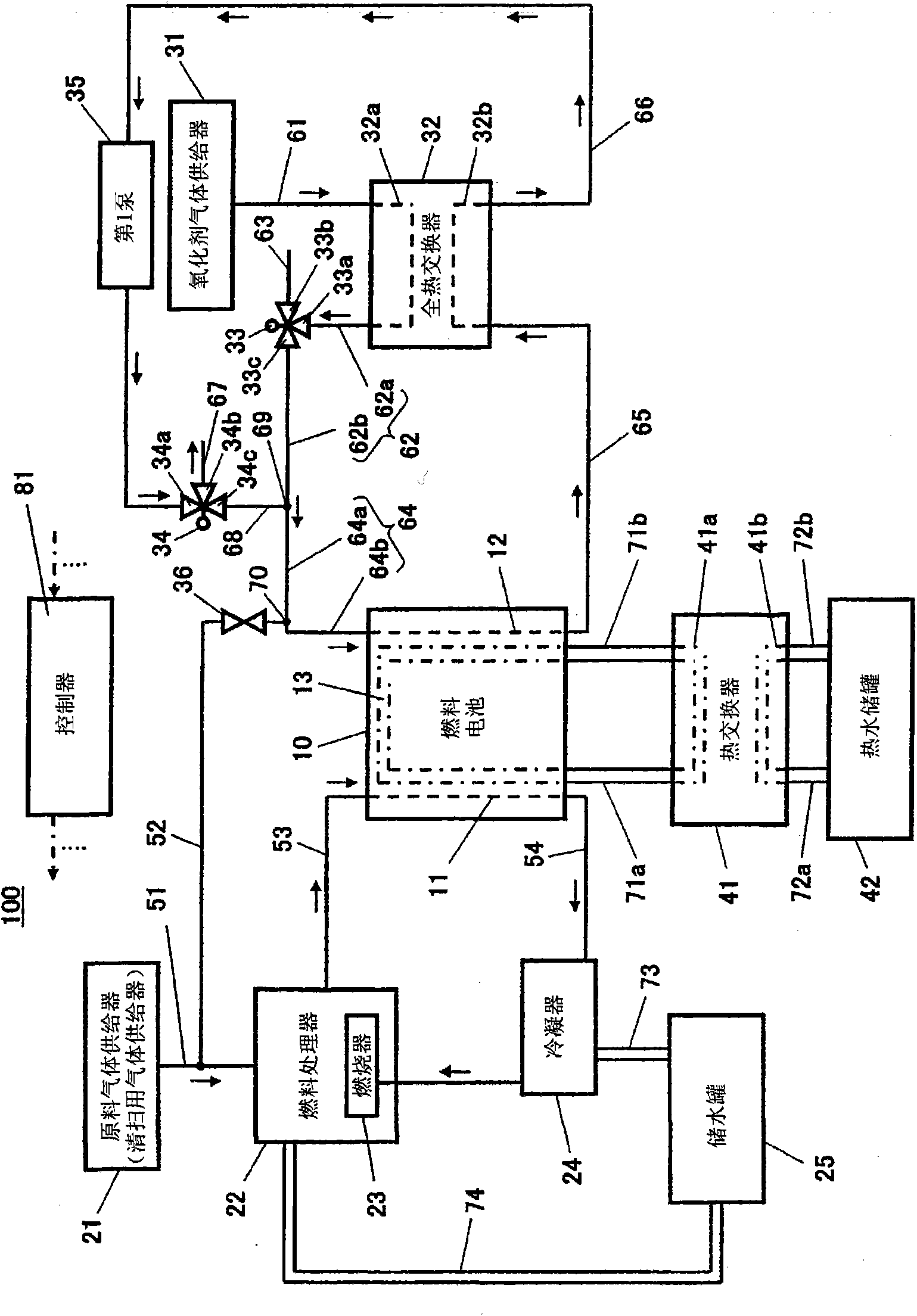

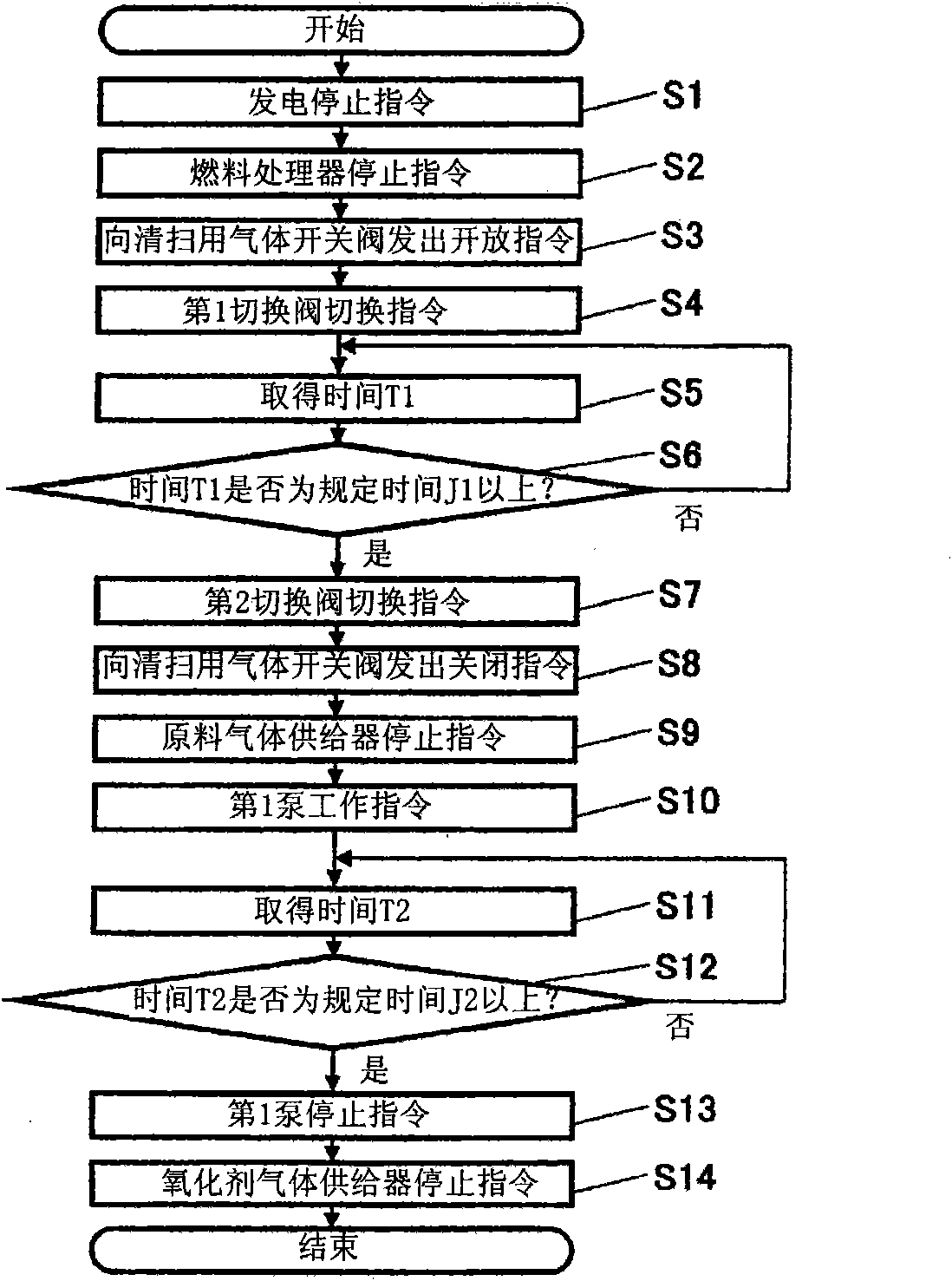

[0139] figure 1 It is a schematic diagram showing a schematic configuration of the fuel cell system according to Embodiment 1 of the present invention, and schematically shows the flow of reactant gas during power generation by the fuel cell.

[0140] [Configuration of fuel cell system]

[0141] Such as figure 1 As shown, the fuel cell system 100 according to Embodiment 1 includes the fuel cell 10 , a fuel gas supply system, an oxidant gas supply system, a cooling system, and a controller 81 . The fuel gas supply system is configured to supply fuel gas to the fuel cell 10 and includes a raw material gas supplier (scavenging gas supplier) 21 , a fuel processor (fuel gas supplier) 22 , and a condenser 24 . In addition, the oxidant gas supply system is configured to supply oxidant gas to the fuel cell 10 , and has an oxidant gas supplier 31 and a total heat exchanger (moisture exchanger) 32 .

[0142] First, the configuration of the fuel cell 10 will be described below.

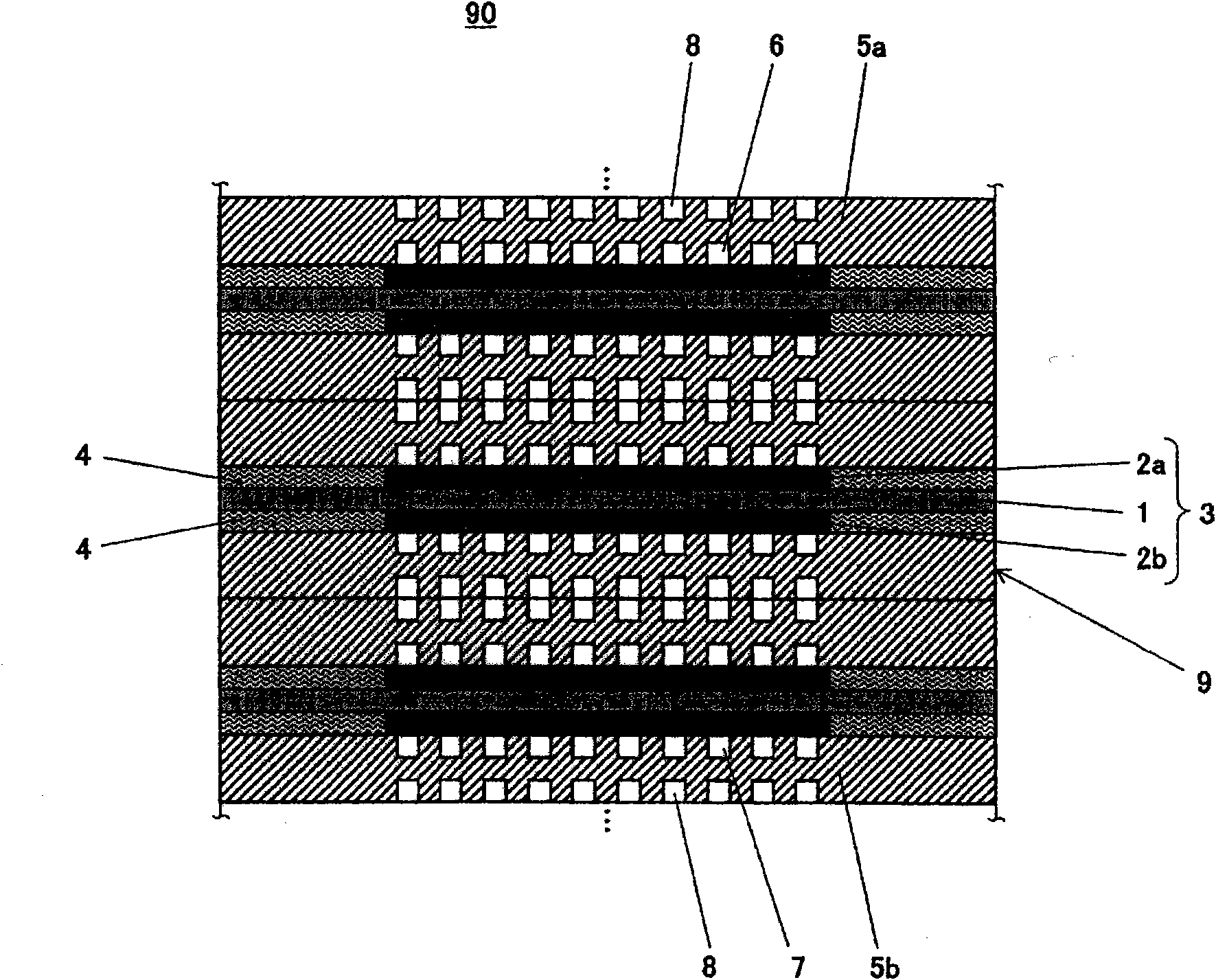

[01...

Embodiment approach 2

[0188] Figure 6 It is a schematic diagram showing a schematic configuration of a fuel cell system according to Embodiment 2 of the present invention, and schematically shows the flow of reactant gas during fuel cell power generation operation. Figure 7 It is a flowchart schematically showing the contents of the operation stop operation program stored in the storage unit of the controller in the fuel cell system according to the second embodiment.

[0189] Such as Figure 6 As shown, the basic configuration of the fuel cell system 100 according to Embodiment 2 is the same as that of the fuel cell system 100 according to Embodiment 1, but differs in that a voltage detector 82 is provided. Specifically, the voltage detector 82 is connected between a pair of electrical output terminals (not shown) of the fuel cell 10 . Also, the voltage detector 82 communicates the detected voltage value to the controller 81 . In addition, as the voltage detector 82, a well-known voltage dete...

Embodiment approach 3

[0194] Figure 8 It is a schematic diagram showing a schematic configuration of a fuel cell system according to Embodiment 3 of the present invention, and schematically shows the flow of reactant gas when the fuel cell generates electricity. Figure 9 It is a flowchart schematically showing the contents of the operation stop operation program stored in the storage unit of the controller in the fuel cell system according to the third embodiment.

[0195] Such as Figure 8 As shown, the basic configuration of the fuel cell system 100 according to Embodiment 3 is the same as that of the fuel cell system 100 according to Embodiment 1, but differs in that a temperature detector 84 is provided. Specifically, the temperature detector 84 is arranged in the middle of the first heat medium outgoing path 71a so as to be able to detect the temperature of the fuel cell 10, and is configured to detect the temperature of the first heat medium discharged from the fuel cell 10 as a fuel The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com