Injection molding machine having a mechanical amplifier

An amplifier, mechanical technology, used in instruments, force/torque/work measuring instruments, measuring devices, etc., to solve problems such as unfavorable measurement results, influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

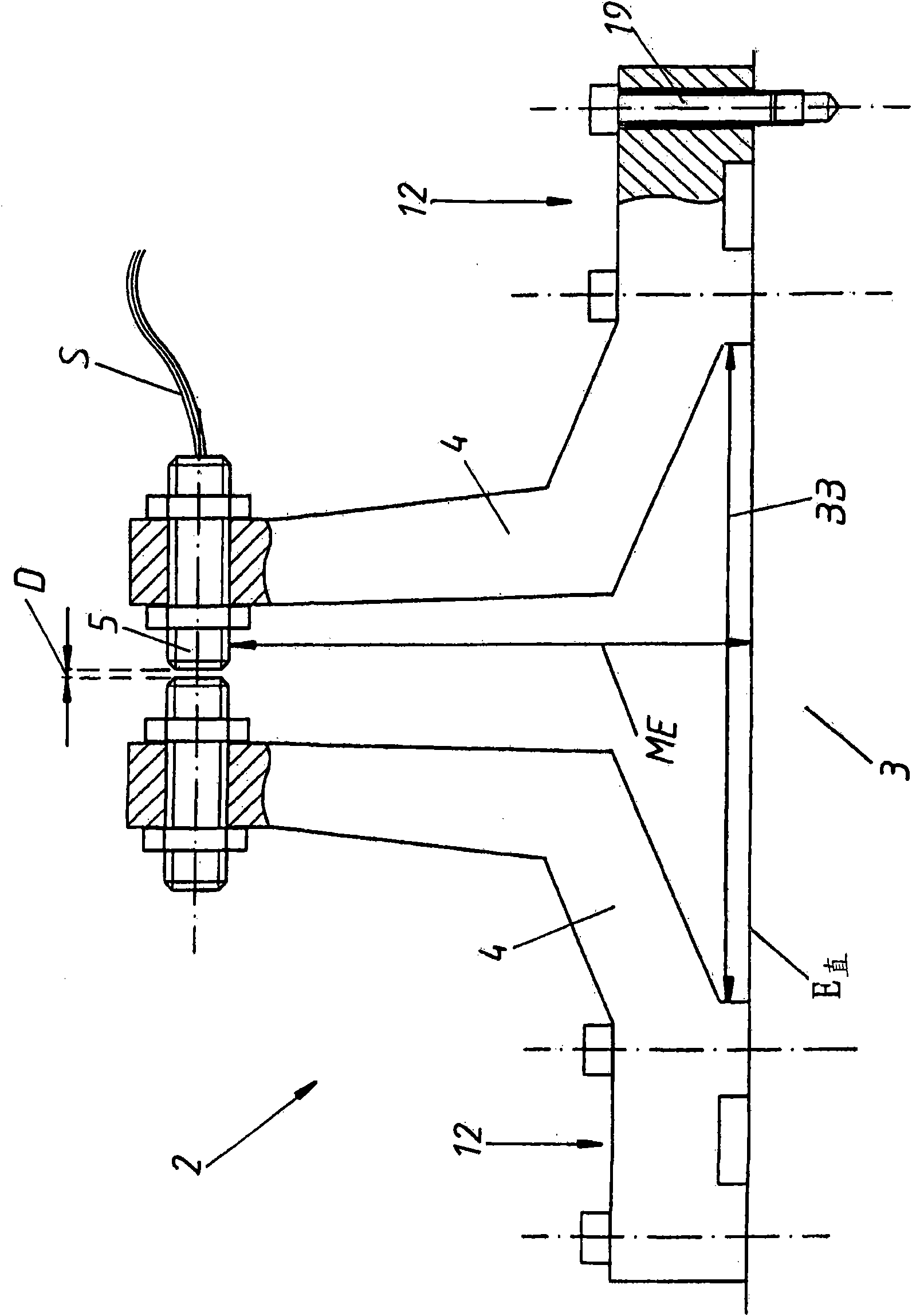

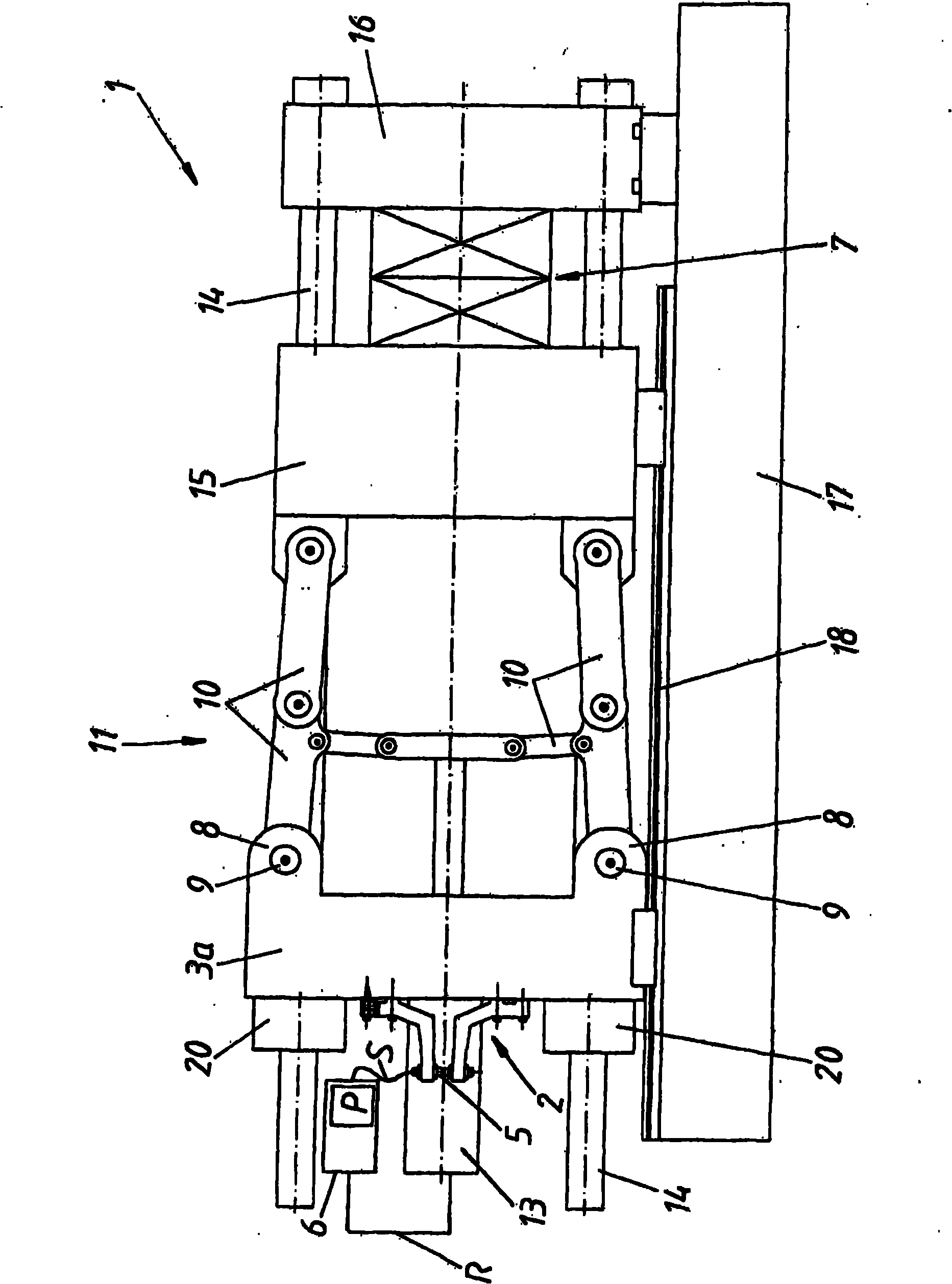

[0027] figure 1 A detail of the mechanical amplifier 2 is shown, wherein an extension 4 substantially perpendicular to the flexure surface E of the machine part 3 can be seen. The extension 4 is configured as an L-shape or a mirror-symmetrical L-shape. In this case, the fastening regions 12 (flanges) are arranged at a distance BB from one another on the machine part 3 . In this case, this distance BB is slightly greater than the distance ME between measuring sensor 5 and machine part 3 . here figure 1 , the machine part 3 is not bent or deformed, so the distance D between the two parts of the measuring sensor 5 is relatively small or minimal, and thus the distance between the extensions 4 is also relatively small or minimal.

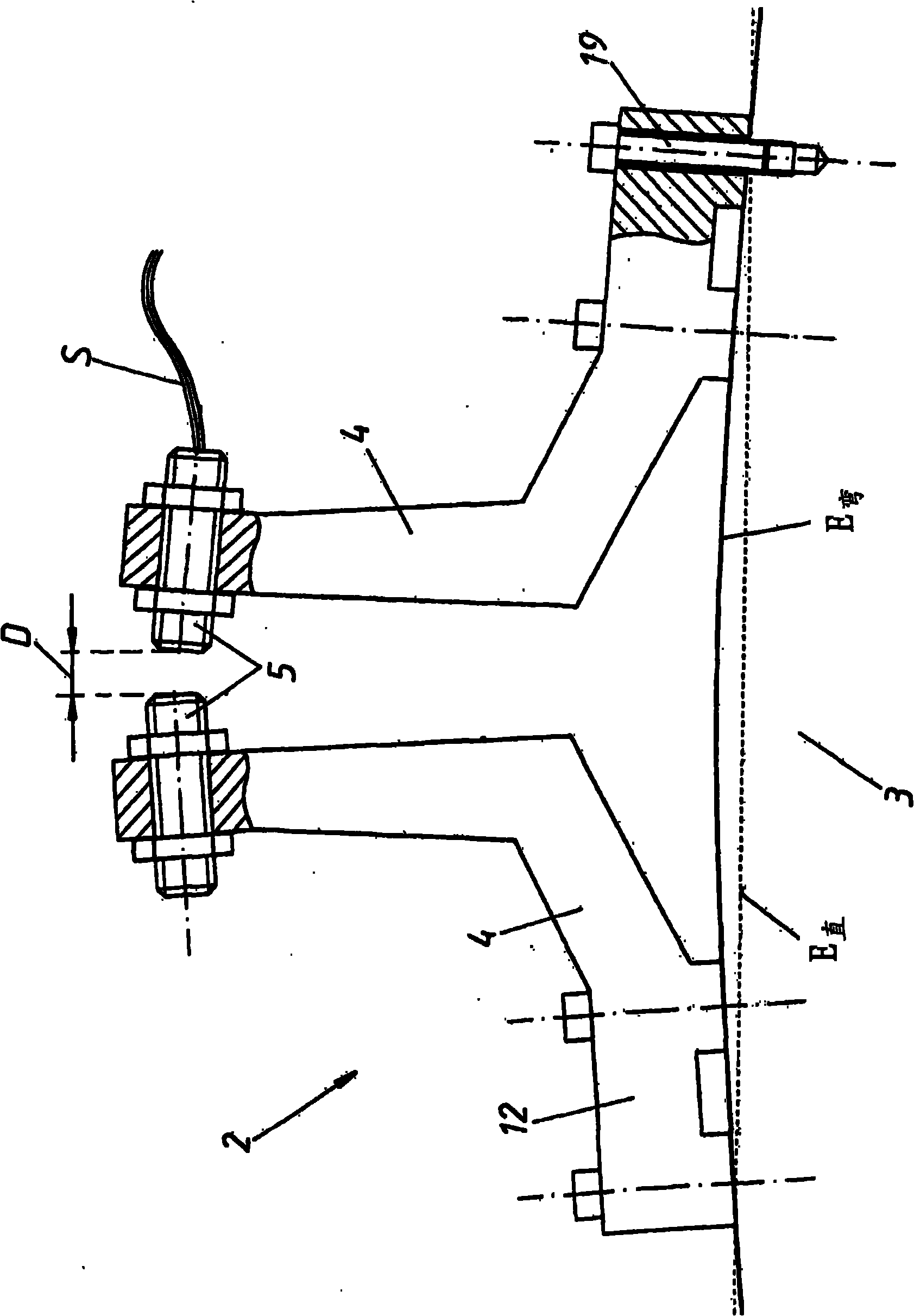

[0028] opposite of this, figure 2 A strong curvature of the machine part 3 is shown (illustrated exaggeratedly), so that the flexure surface Ebend is curved relative to the straight flexure surface E shown with dashed lines. The bending of the mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com