Pumping unit system and power saving control method thereof

A technology of pumping unit and sucker rod, which is applied in the control system, automatic control system of drilling, mechanical equipment, etc., to achieve the effect of reducing power, reducing negative work and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be specifically described below with reference to the accompanying drawings.

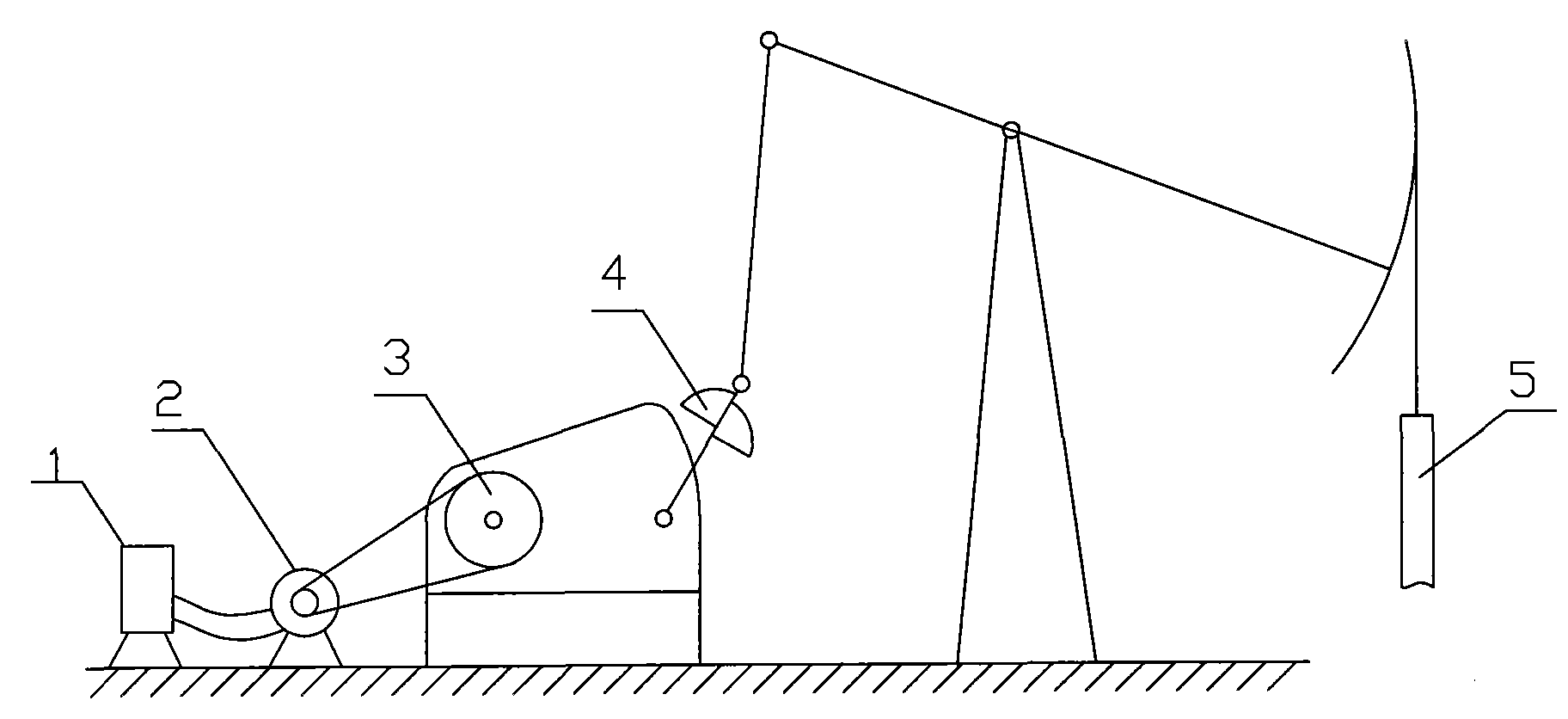

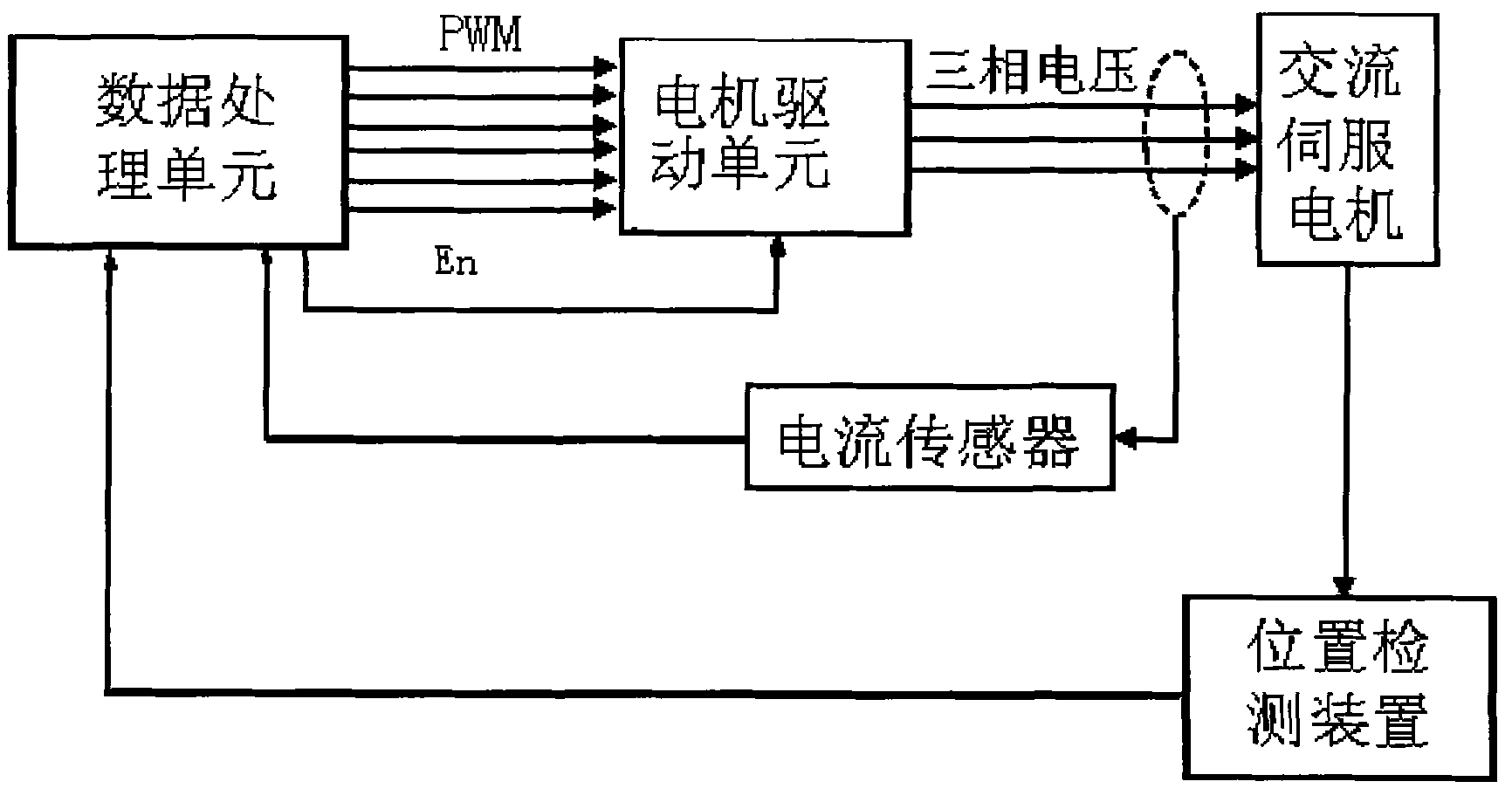

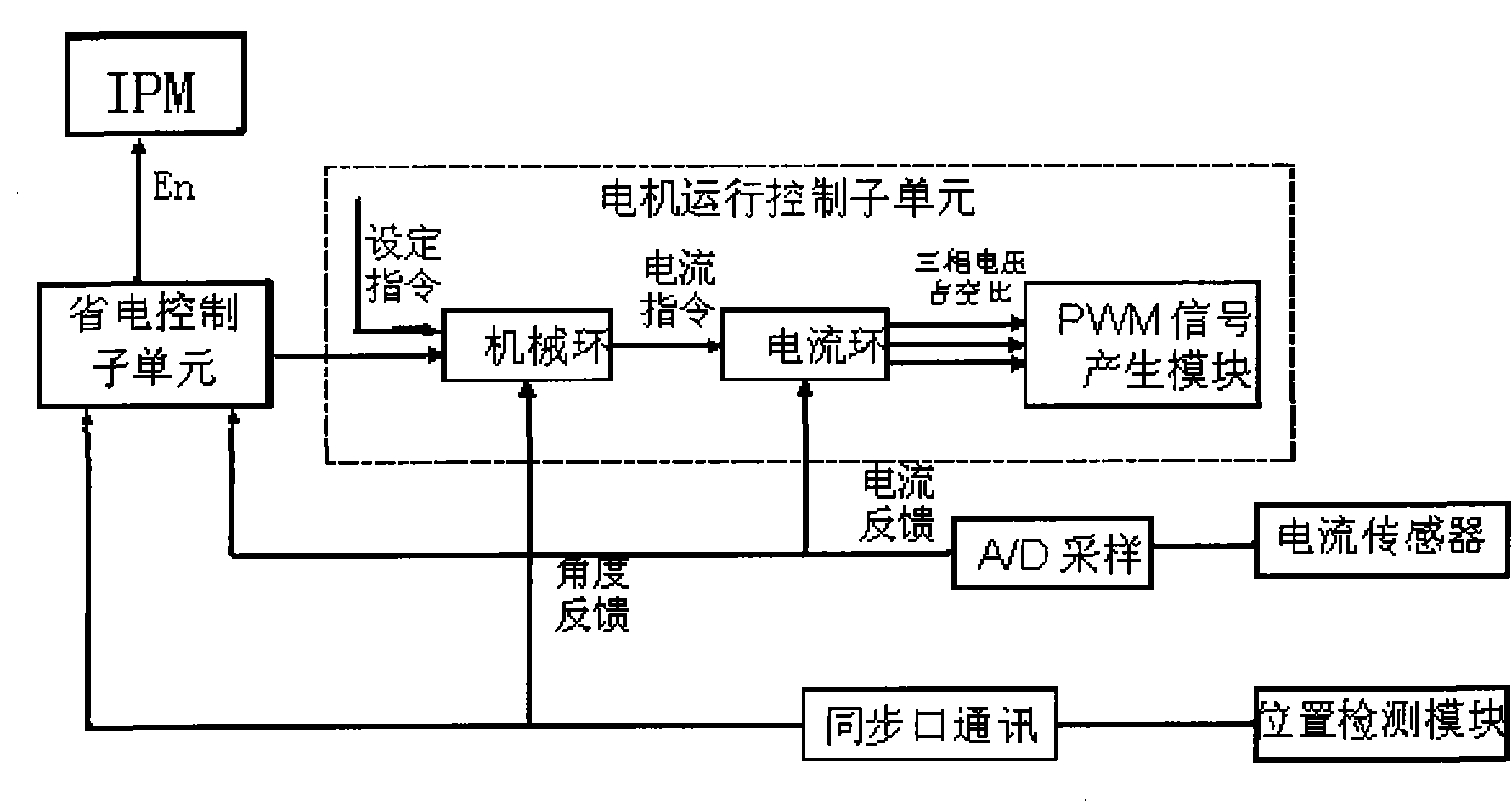

[0030] figure 1 is the schematic diagram of the pumping unit system, figure 2 It is a schematic diagram of the motor drive system control. Such as figure 1 As shown, the pumping unit system includes a drag motor 2, a transmission part 3, a counterweight 4 (and a sucker rod 5, and the drag motor 1 drives the sucker rod 5 to reciprocate up and down through the transmission part 2. The sucker rod 5 is controlled by a Weight 4 to balance.The pumping unit system also includes a control module 1, which can be implemented in the form of a control box during specific implementation, such as figure 1 shown. The shaft of the drag motor is provided with a position detection module, and the power input side of the motor is provided with a current sensor. The control module 1 receives the information representing the position of the drag motor output by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com