Edge face structure of laminated film, method of processing edge face, liquid ejection nozzle with processed edge face, and process for producing the same

A technology for liquid discharge and end face treatment, applied in rigid/semi-rigid container manufacturing, thin material handling, container manufacturing machinery, etc. Sufficient safety and hygiene, the effect of ensuring safety and hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

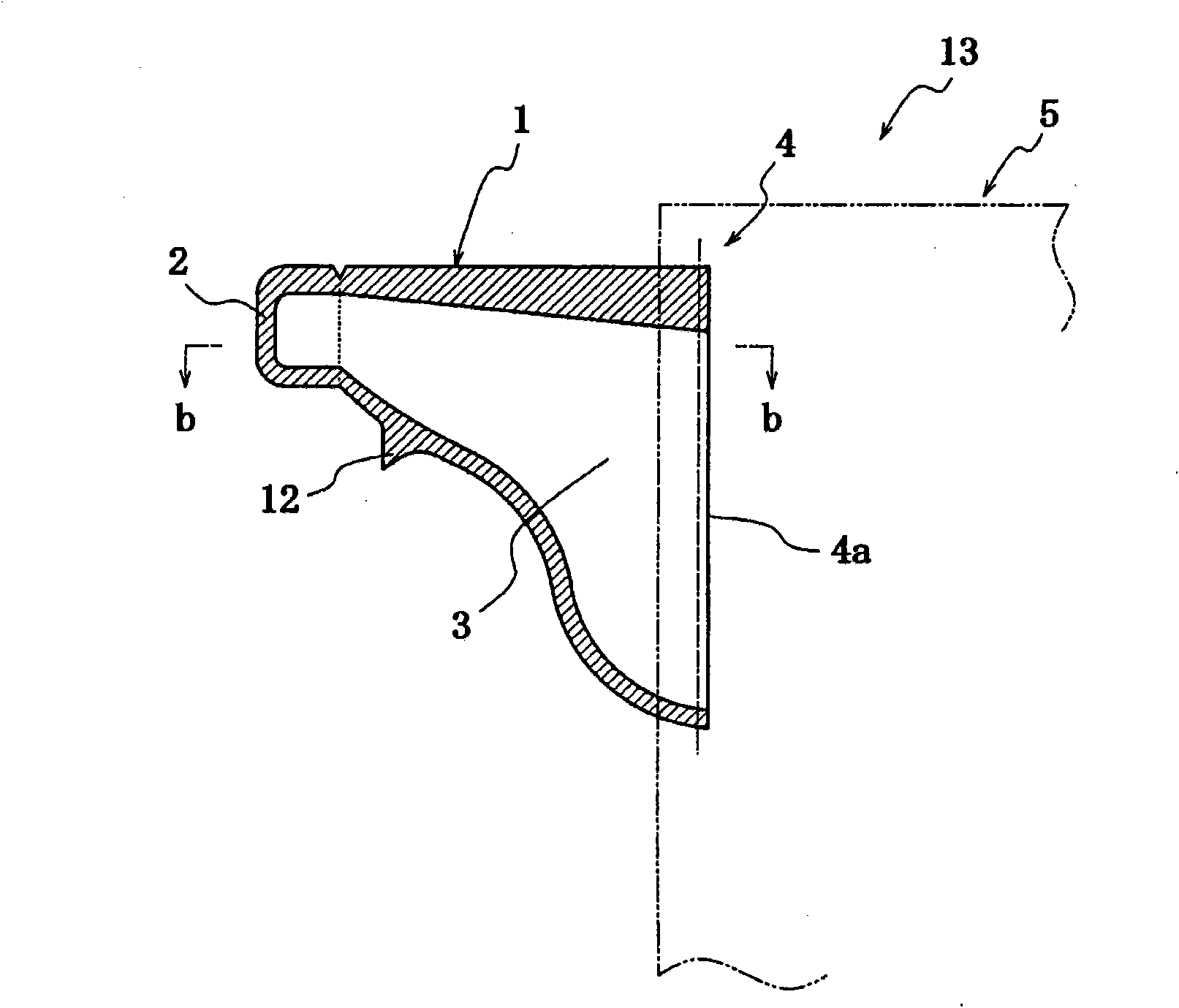

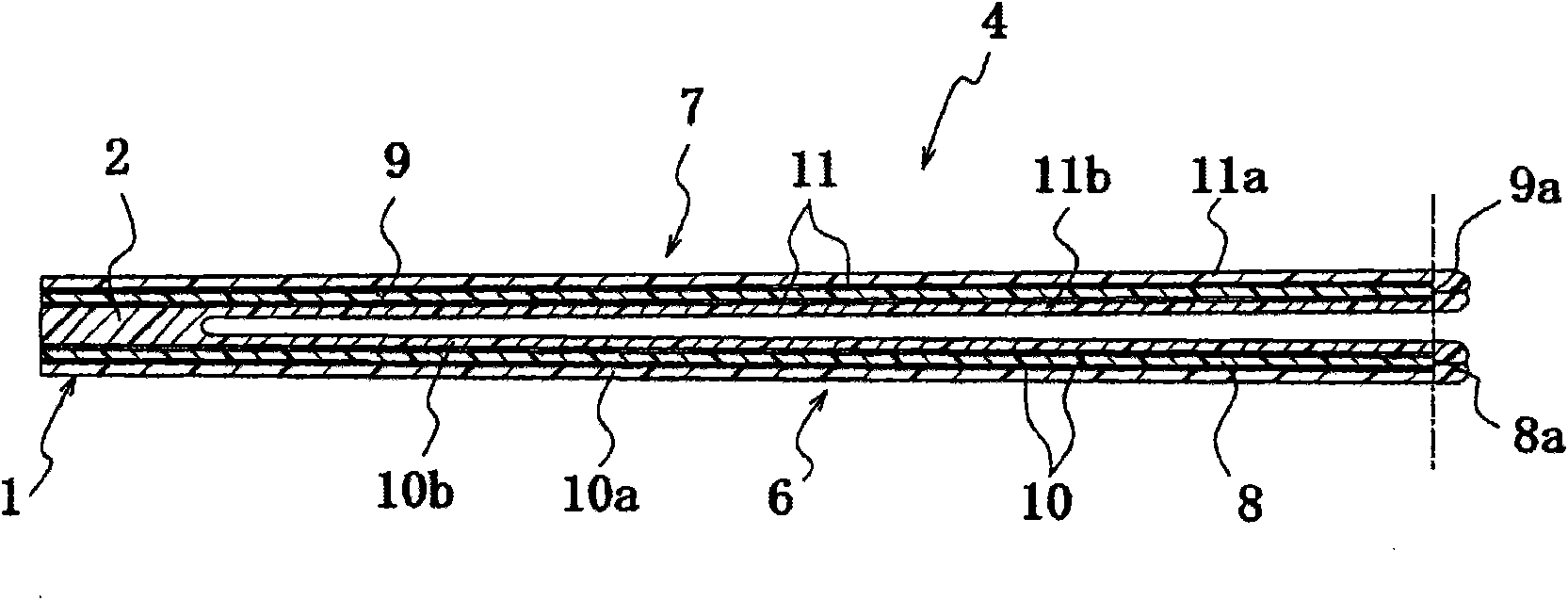

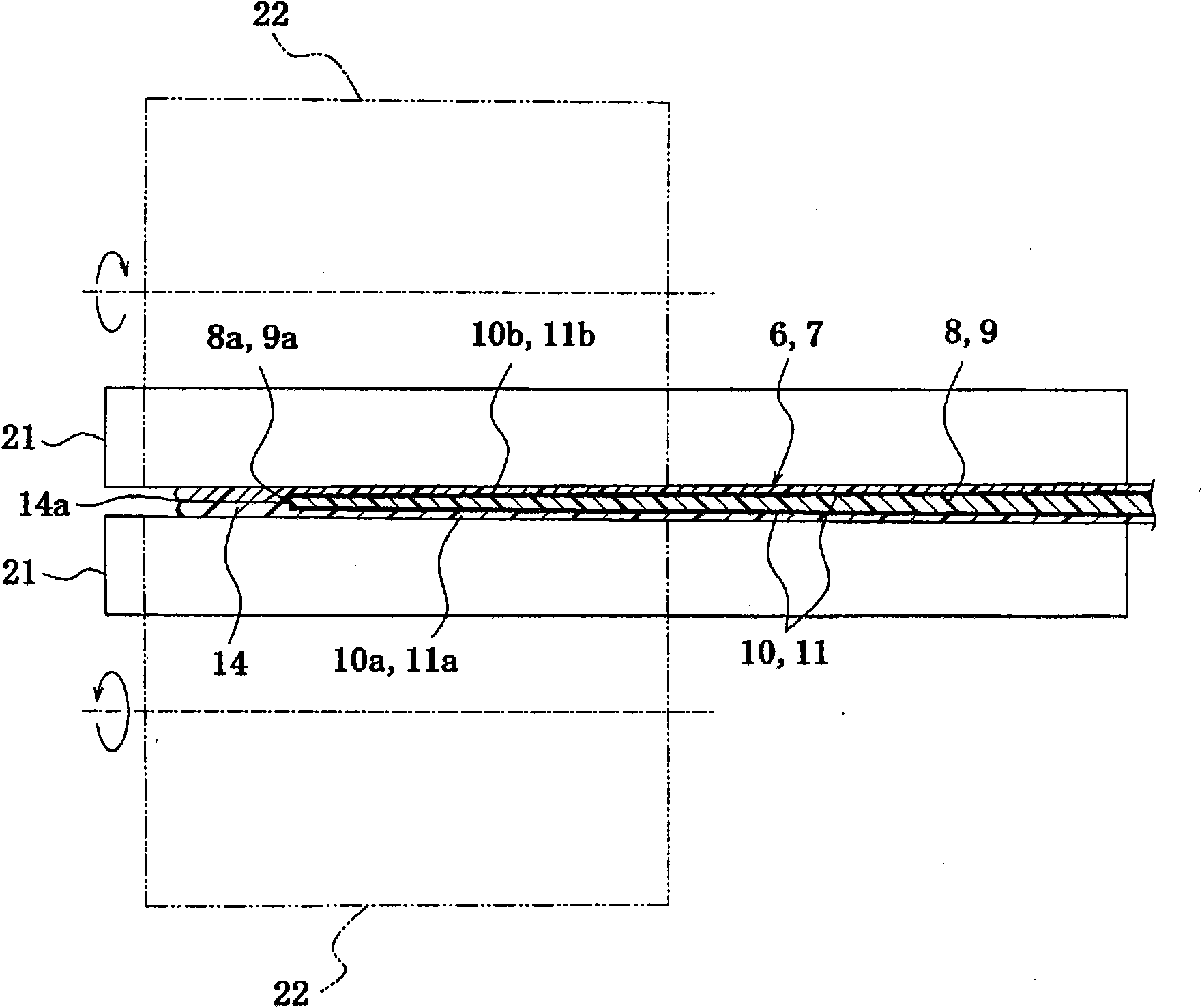

[0032] Hereinafter, embodiments of the present invention will be described by taking, as an example, a liquid discharge nozzle formed using a laminated film having a three-layer structure in which sealing layers are disposed on both sides of a base film layer.

[0033] Fig. 1 is a view showing an embodiment of a liquid discharge nozzle of the present invention, and Fig. 1(b) is an enlarged cross-sectional view along line b-b of the side view of the discharge nozzle shown in Fig. 1(a).

[0034] The parts indicated by hatching in the figure indicate the welding provided on the peripheral part of the two laminated films on the front and back sides or a laminated film folded in half from the central part, except for the part that becomes the base end side of the discharge nozzle. The welded part 1 can form a discharge port at the front end of the discharge flow path 3 formed inside the welded part 1 by breaking or cutting off the welded part 2 at the front end.

[0035] A part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com