Levelling device and method of charging an oven chamber of a coke oven battery

A technology of coking oven group and furnace chamber, which is applied in the direction of furnace safety device, coking oven, mechanical treatment of coal loaded into the furnace, etc., which can solve the problems that cannot be considered and compensated, and achieve high filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

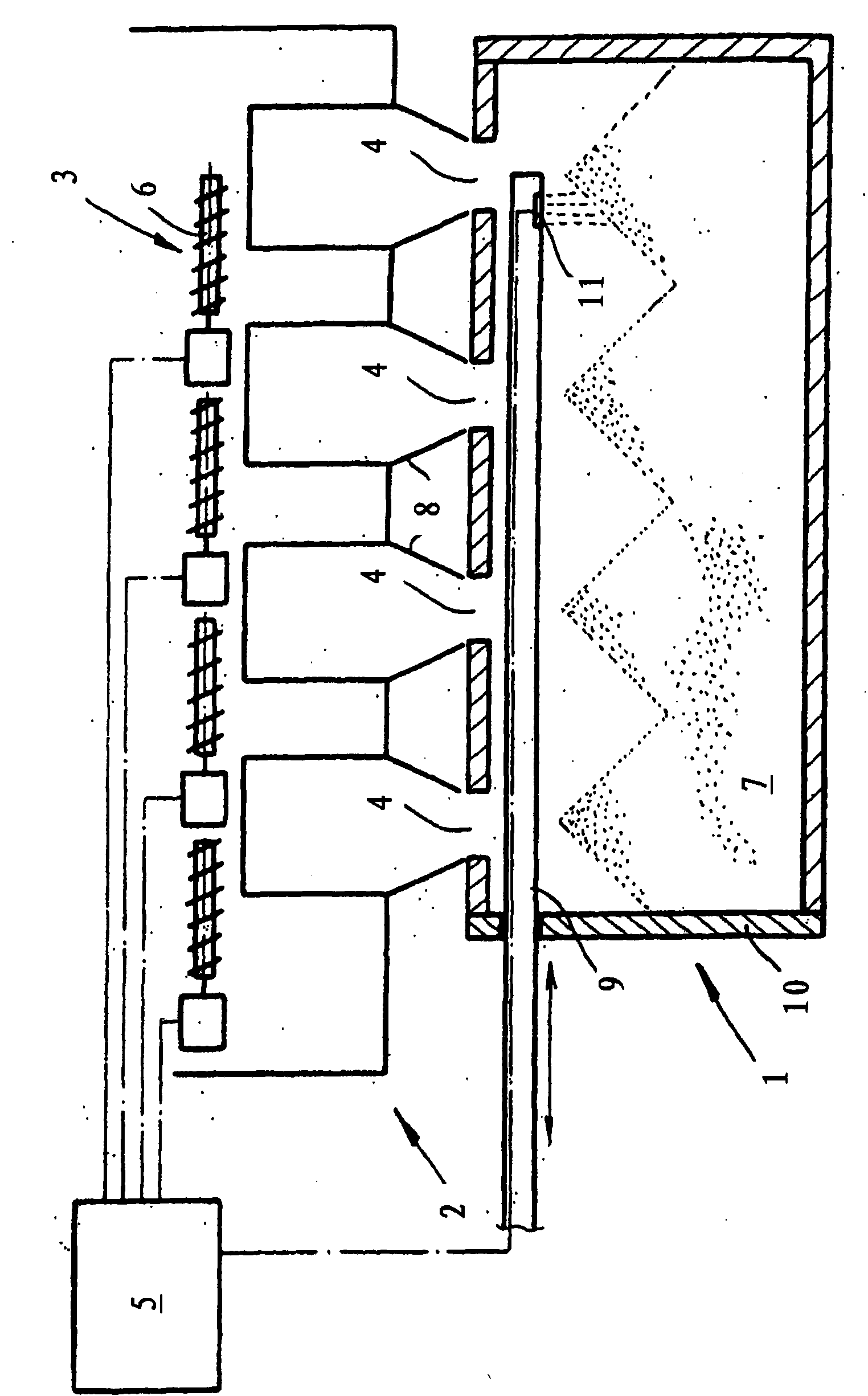

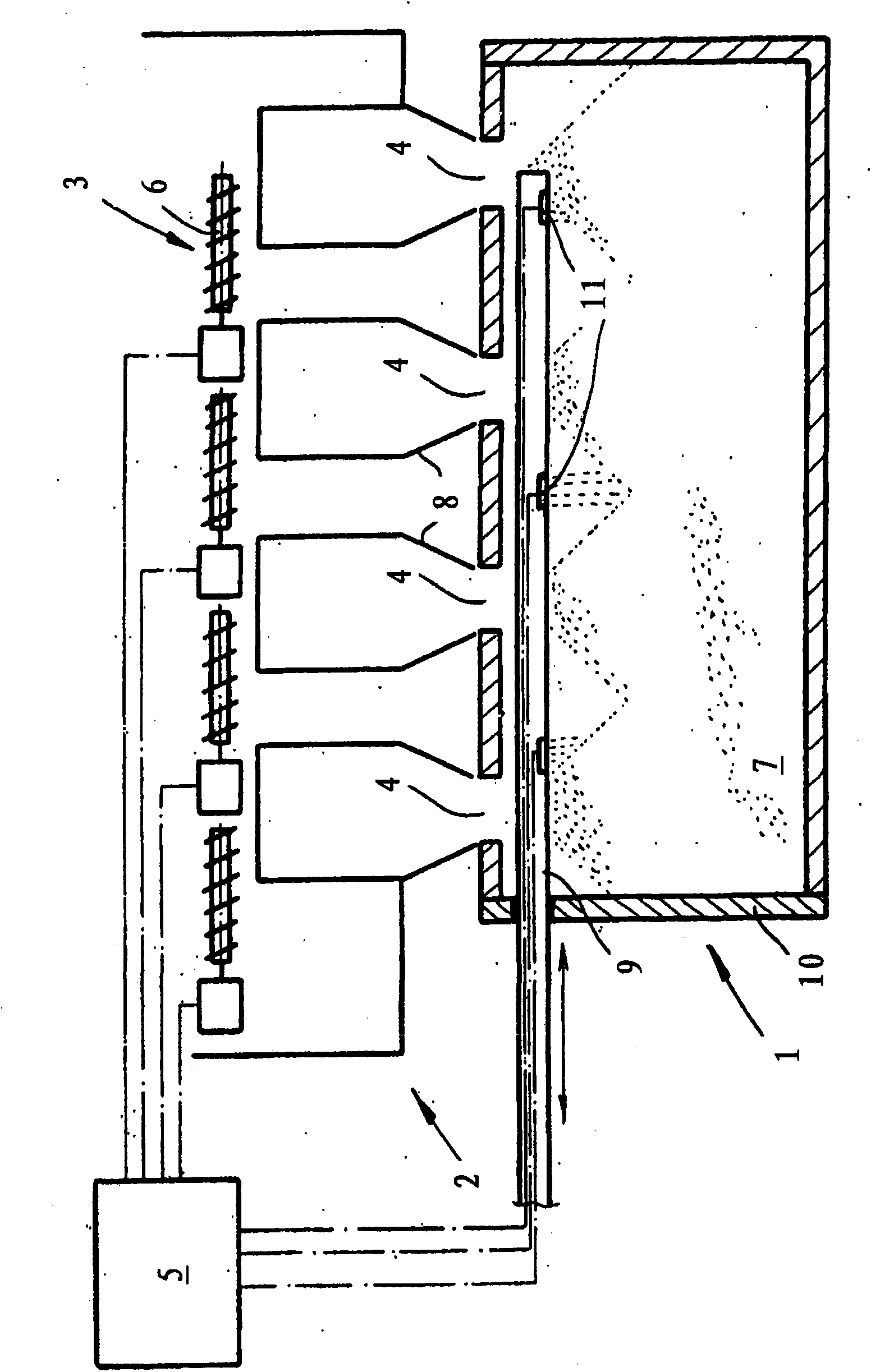

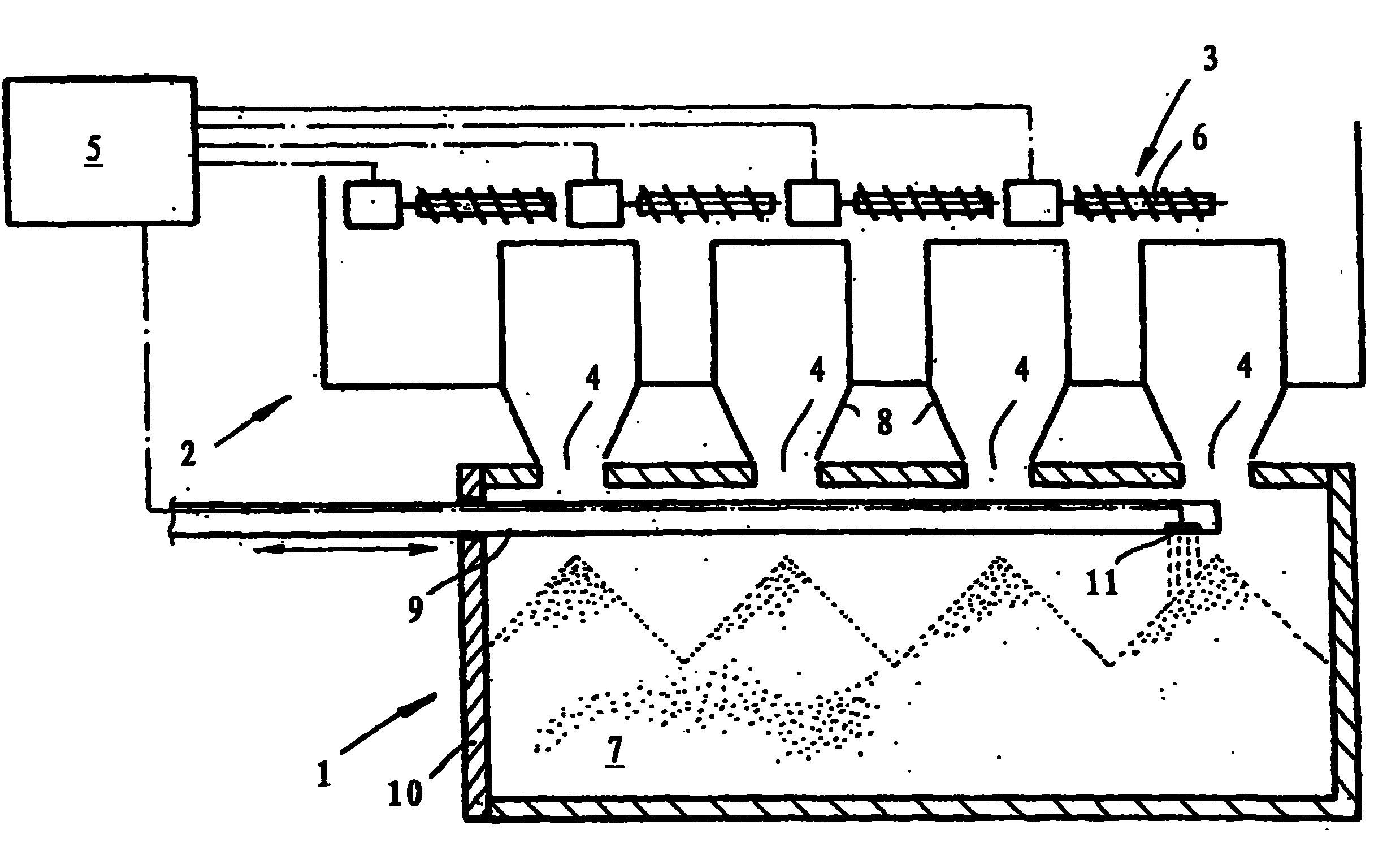

[0018] exist figure 1 shows one oven chamber 1 of a coke oven battery during the filling process. For this purpose, a filling machine 2 movable over the battery of coke ovens is provided with a plurality of conveying devices 3 which are each assigned to a filling opening 4 of the furnace chamber 1 . The conveying devices 3 each comprise a speed-controlled conveying worm 6 connected to a common calculation unit 5 , each conveying coking coal 7 via a coal charging funnel 8 into an associated filling hole 4 . In order to achieve a uniform distribution of the coking coal 7 in the furnace chamber 1 , the leveling rod 9 is introduced into the furnace chamber 1 through a leveling opening in a lateral furnace chamber door 10 and moved in and out in the longitudinal direction. At the front end of the leveling rod 9 is provided a contactless measuring device 11 connected to the computing unit 5 , with which the three-dimensional filling level profile is determined in the longitudinal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com