Forming device of diamond tooth-dividing sintered saw bits

A molding device and diamond technology, which is applied in the tool manufacturing of sawing machines, metal sawing equipment, metal processing equipment, etc., can solve the problems of low labor efficiency, high labor intensity of workers, affecting efficiency, etc., and reduce mold and labor costs. , reduce the labor intensity of workers and realize the effect of semi-automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

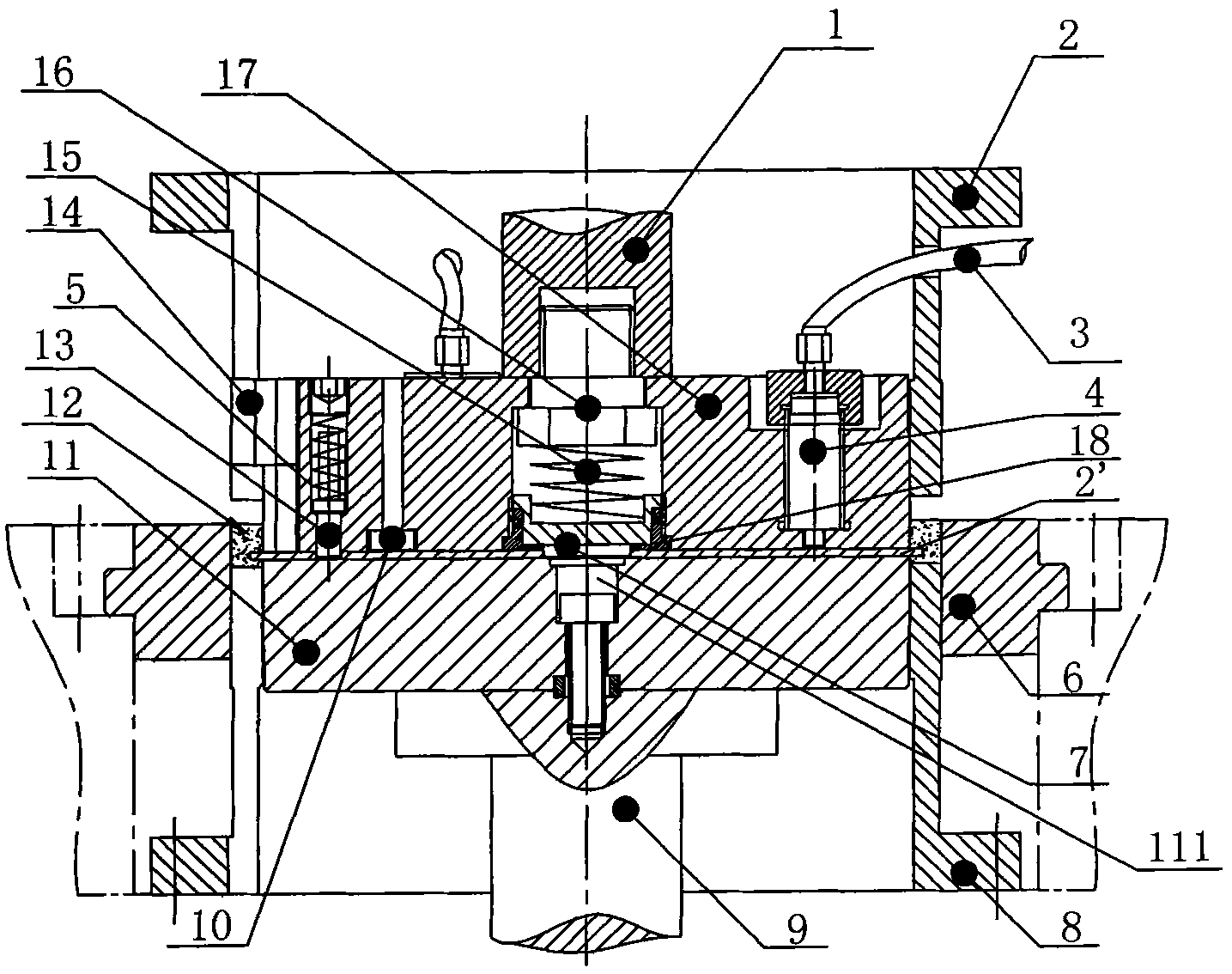

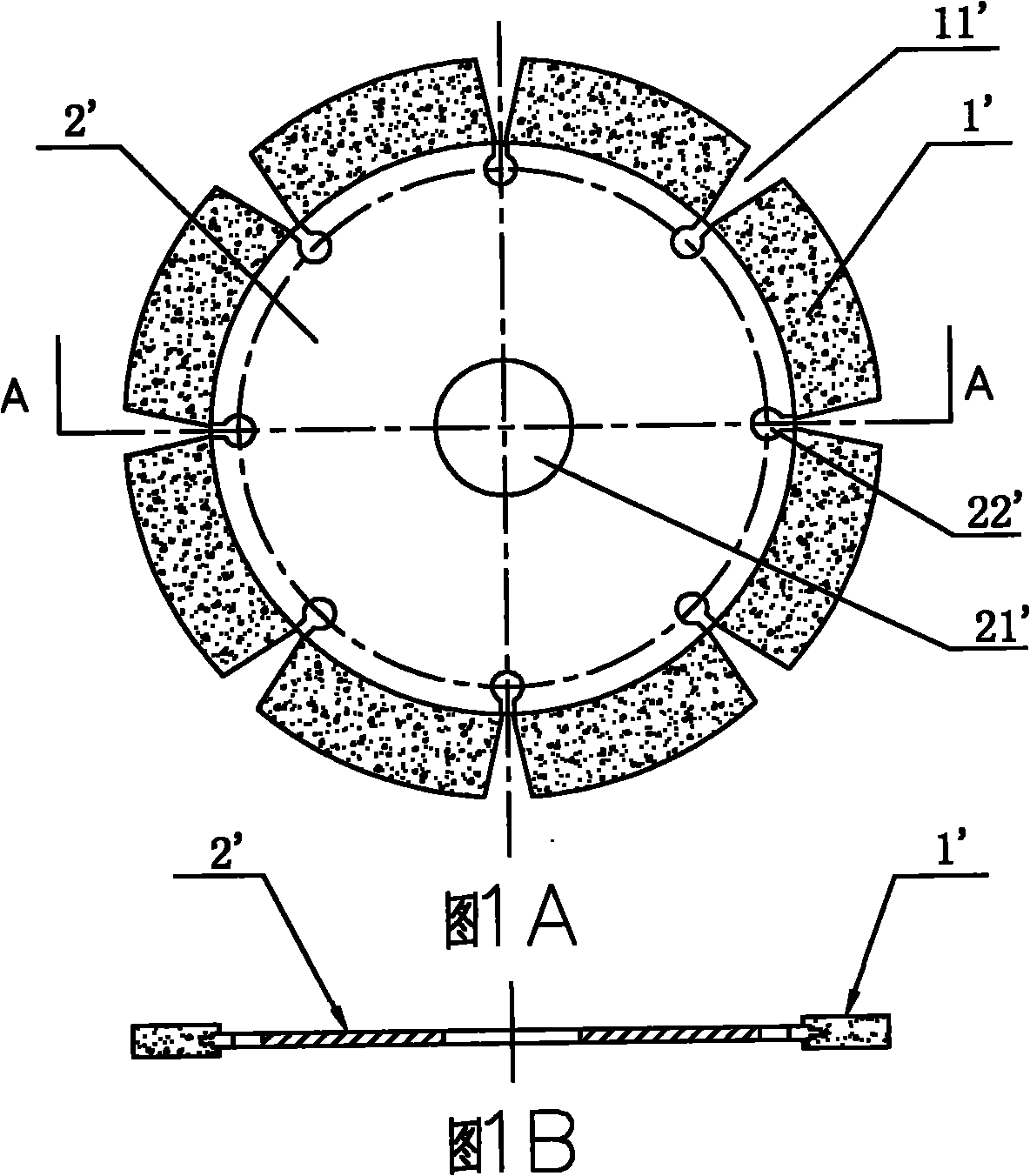

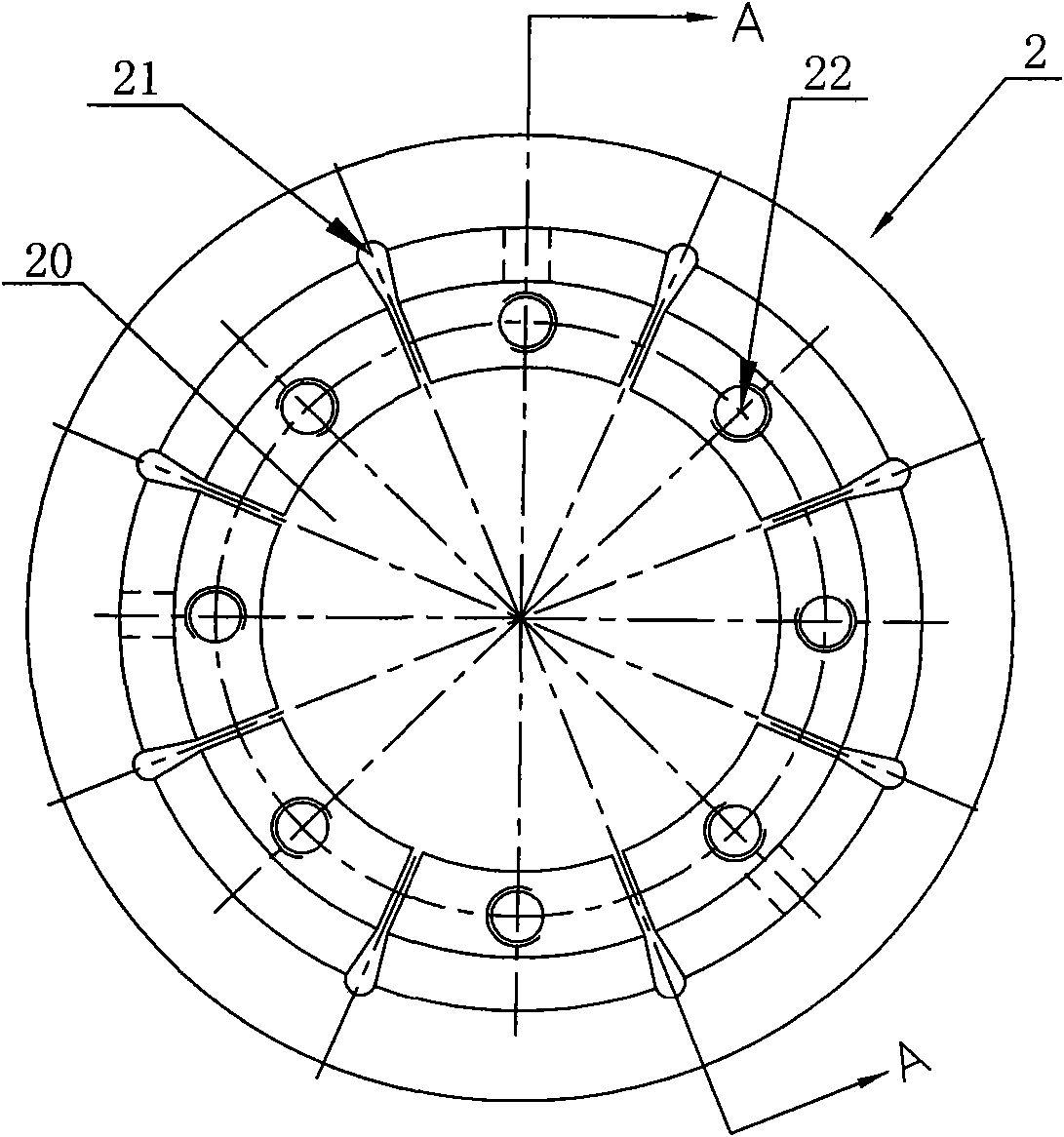

[0029] Such as figure 1 , Figure 1A , Figure 1B , figure 2 and Figure 2A Shown, a kind of diamond split teeth sintered saw blade shaping device, it comprises:

[0030] An upper pressing head 2: its side wall is provided with an upper split tooth gap 21 corresponding to each gap 11' between the adjacent cutter heads 1' of the split-tooth saw blade that is required to be pressed. The upper pressing head 2 includes a tube body and a disc, and the tube body and the disc are integrally formed. The disc is arranged at one end of the tube body, the central axis of the tube body is aligned with the central axis of the disc, the diameter of the disc is larger than the outer diameter of the tube body, and the disc is provided with an opening communicating with the cavity of the tube body 20, the central axis of the opening 20 is aligned with the central axis of the pipe body, and the diameter of the opening 20 is smaller than the internal diameter of the pipe. A uniform ring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com