Semisolid forming method for aluminum-base composite material creeper tread of special vehicle and forming mold thereof

A semi-solid forming technology of aluminum-based composite materials, which is applied in the field of semi-solid forming of aluminum-based composite track shoes of special vehicles and its forming dies, can solve problems such as inability to guarantee track shoe performance, track shoe weight, and difficulty in forging forging. Achieve the effect of quality reduction, good parts performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

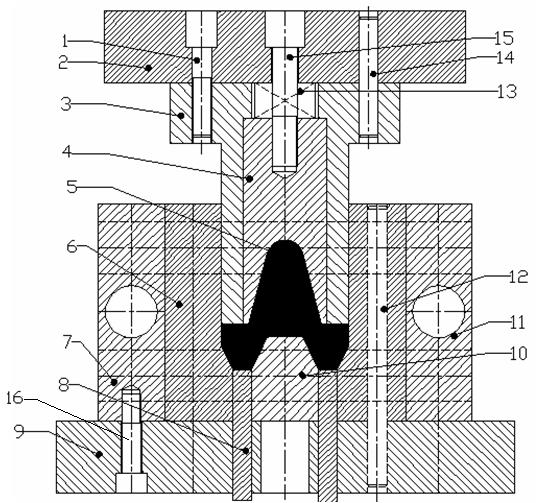

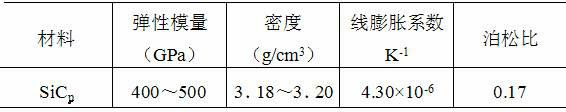

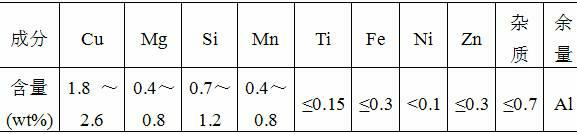

[0013] Specific implementation mode 1: In this implementation mode, the semi-solid forming method of aluminum-based composite track shoes for special vehicles is as follows: 1. SiC p Soak in HF solution with a mass concentration of 10% for 24 hours for pickling, and the SiC after pickling p Wash with distilled water every 1 to 2 hours until the washing solution is neutral; 2. SiC that has been treated in step 1 p Dry in a drying oven at 140°C for 24 to 28 hours, and then grind to powder; 3. Powder SiC p Sinter at 800°C±5°C for 2 to 3 hours, stirring continuously during the sintering process; 4. Weigh 2A50 aluminum alloy and SiC treated in step 3 p , where SiC p Accounting for 2A50 aluminum alloy and SiC p The volume fraction of the total amount is 5vol%~10vol%; 5. Put the weighed SiC p Wrap it with aluminum foil, put it into a stirring crucible and heat it to 600°C~620°C, and keep it warm for 30~40min; Magnesium, pure magnesium accounts for 2A50 aluminum alloy, pure magne...

specific Embodiment approach 2

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step three, the powdered SiC p Sintered at 798°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step three, the powdered SiC p Sintered at 803°C. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com