Milling and planing system

A milling and cutting tool technology, which is applied to earth moving machines/shovels, irrigation pipes, applications, etc., can solve the problems of poor construction quality, fast tool wear, low efficiency, etc., to improve construction efficiency, fast cutting speed, The effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

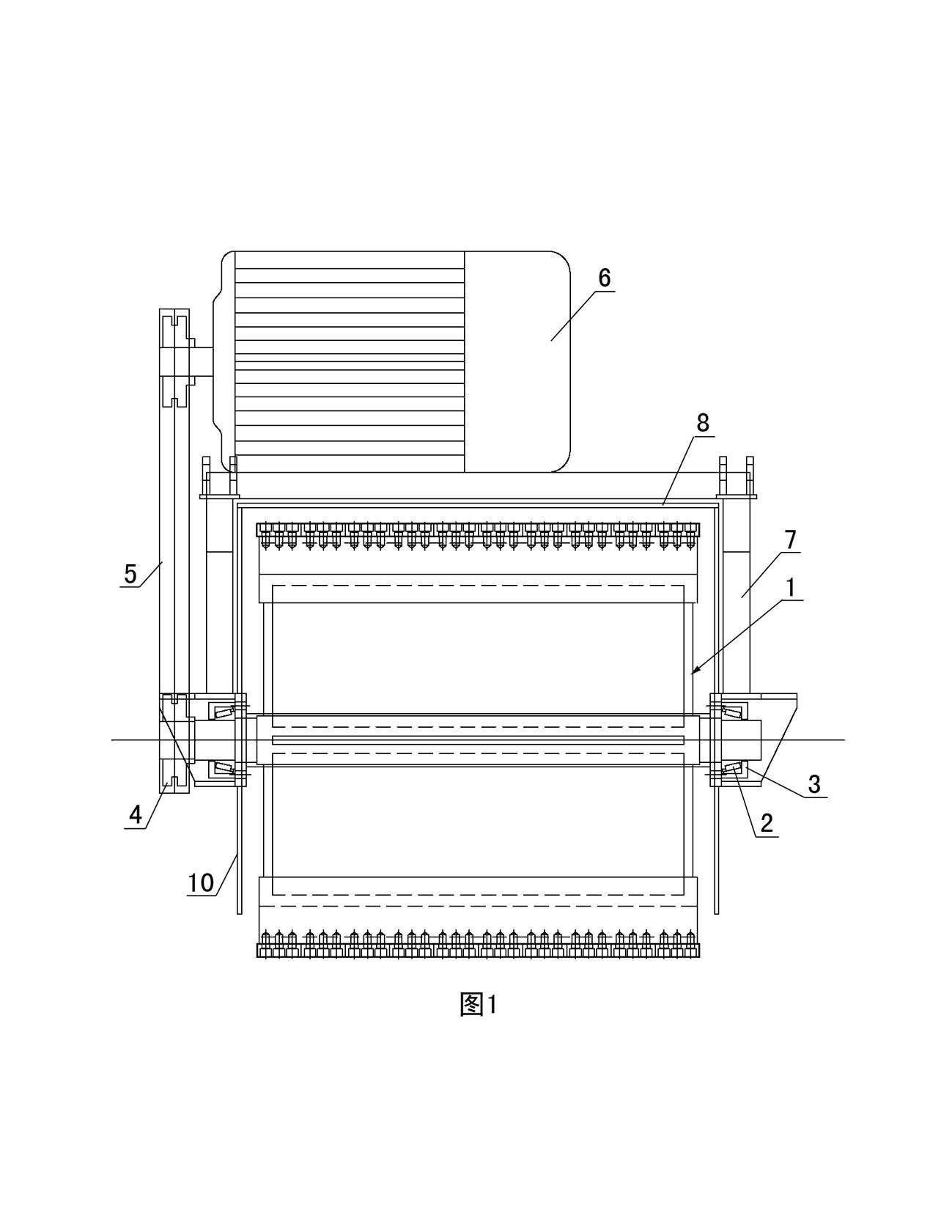

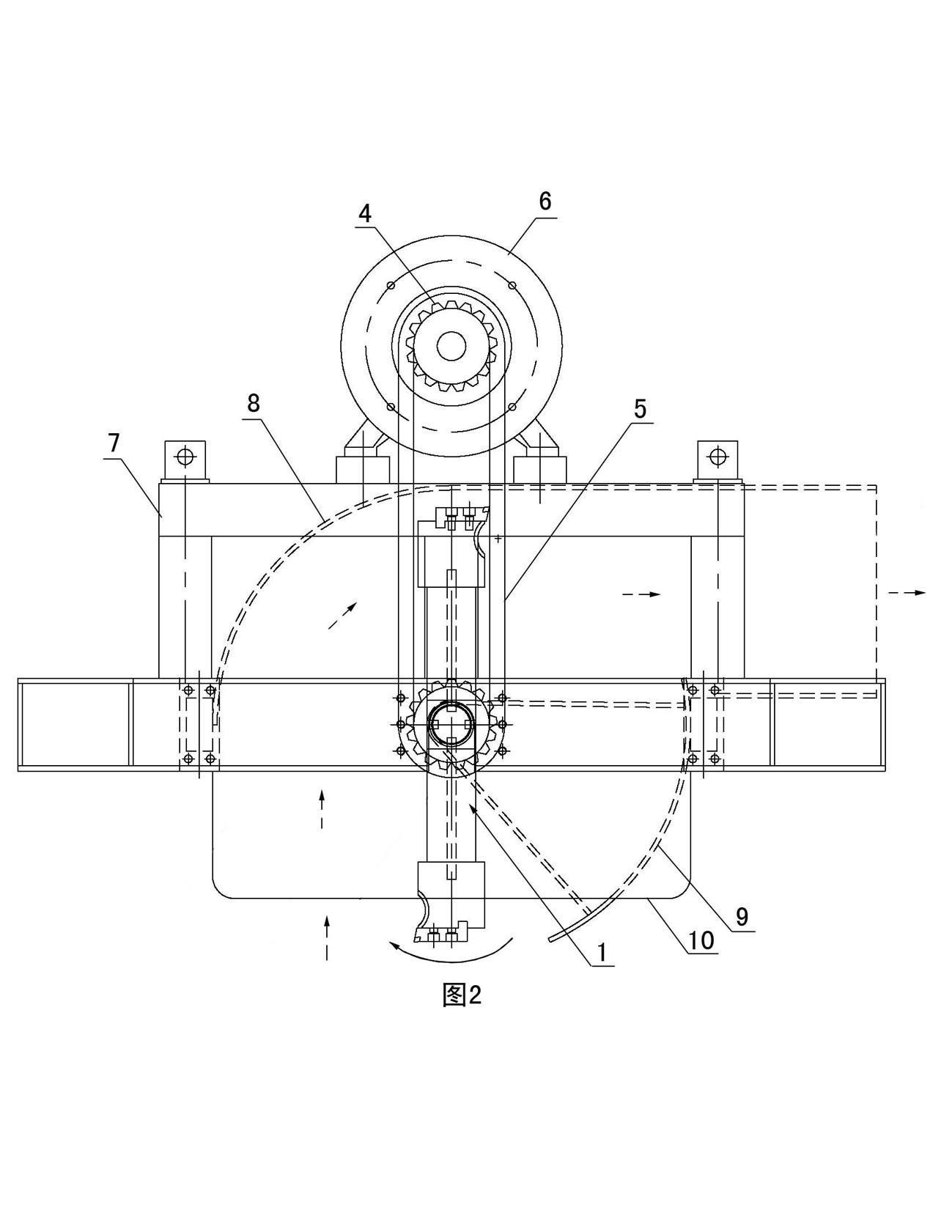

[0023] Examples see figure 1 , figure 2 As shown, this milling system includes a cutter rotor assembly frame 7, a motor 6 fixedly connected to the cutter rotor assembly frame 7, and a cutter rotor assembly 1 rotatably connected to the cutter rotor assembly frame 7. , wherein the output end of the motor 6 drives and connects the tool rotor assembly 1 . The motor 6 can be installed on the upper end or the side end of the cutter rotor assembly structural frame 7, and the present embodiment is installed on the upper end of the cutter rotor assembly structural frame 7.

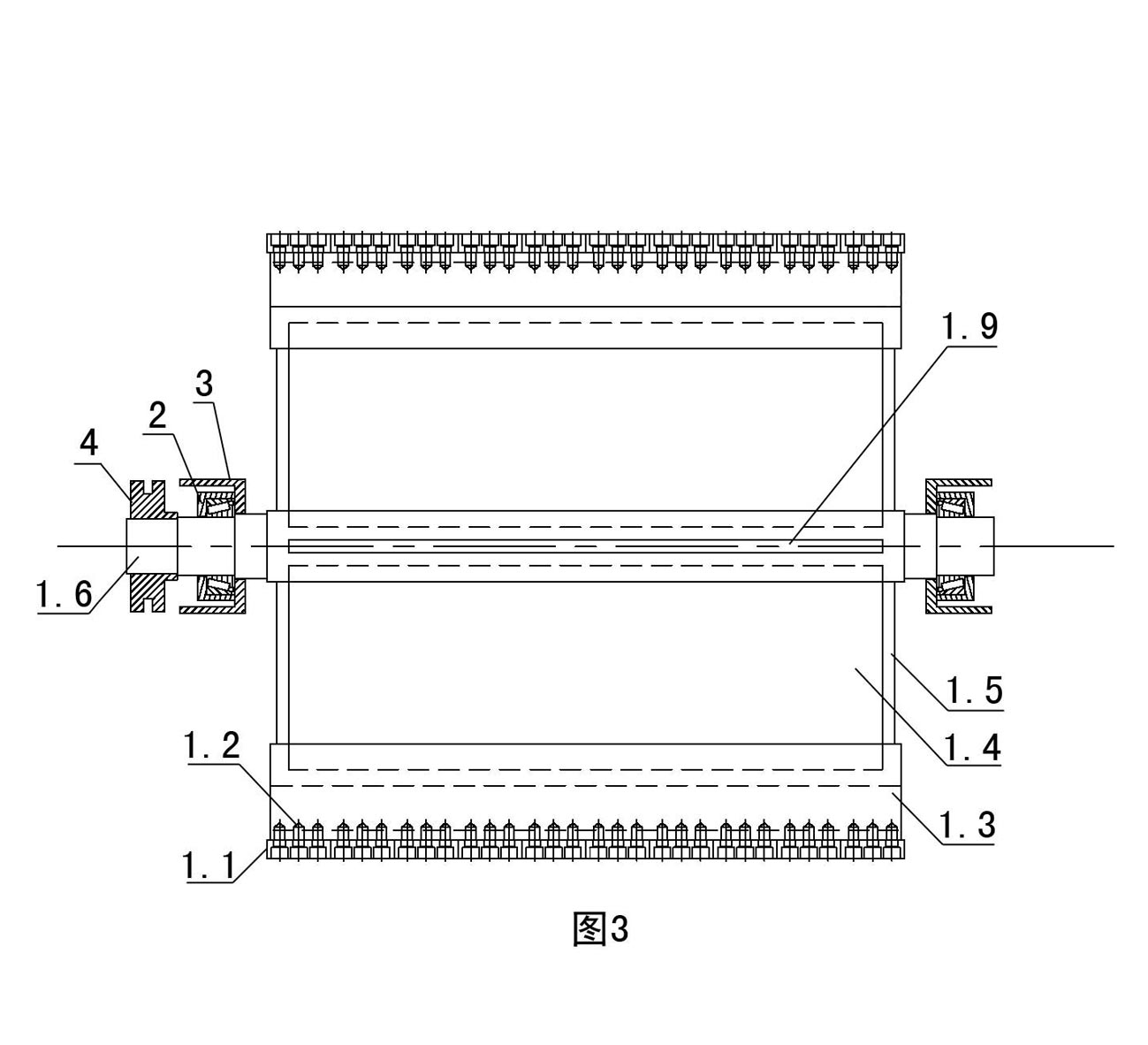

[0024] see figure 2 , image 3 , the cutter rotor assembly 1 is composed of a cutter 1.1, a bolt 1.2, a cutter seat 1.3, a connecting plate 1.4, a reinforcing plate 1.5 and a transmission shaft 1.6, wherein the transmission shaft 1.6 is rotationally connected to the cutter rotor assembly through a bearing 2 and a tile box 3 On the structural frame 7, there are at least two connecting plates 1.4 and they are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com