Silencer for reducing oil circulation rate of compressor

A compressor oil and muffler technology, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve problems such as reducing the oil circulation rate, and achieve the advantages of reducing the noise of dipole acoustic modal resonance and increasing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

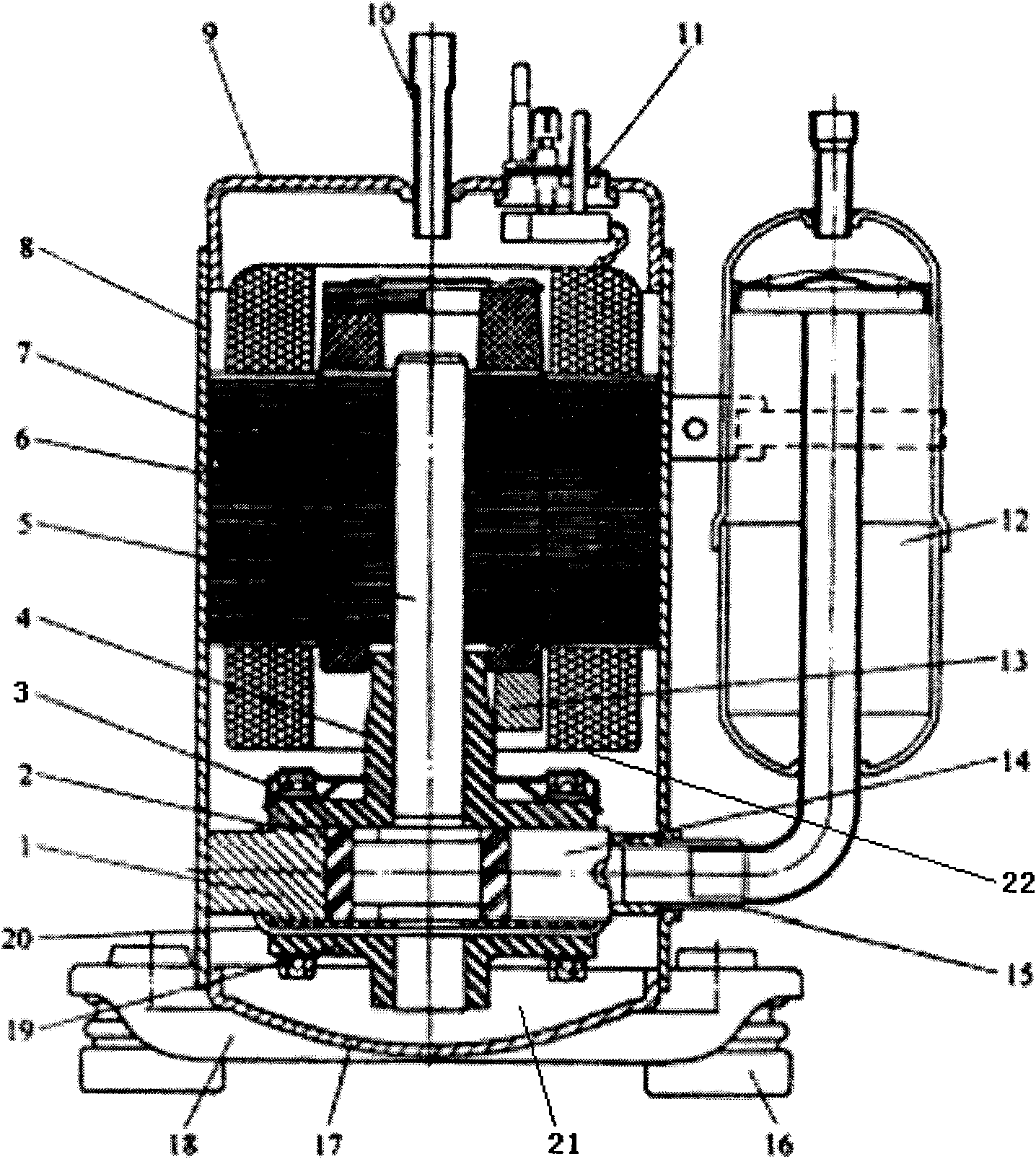

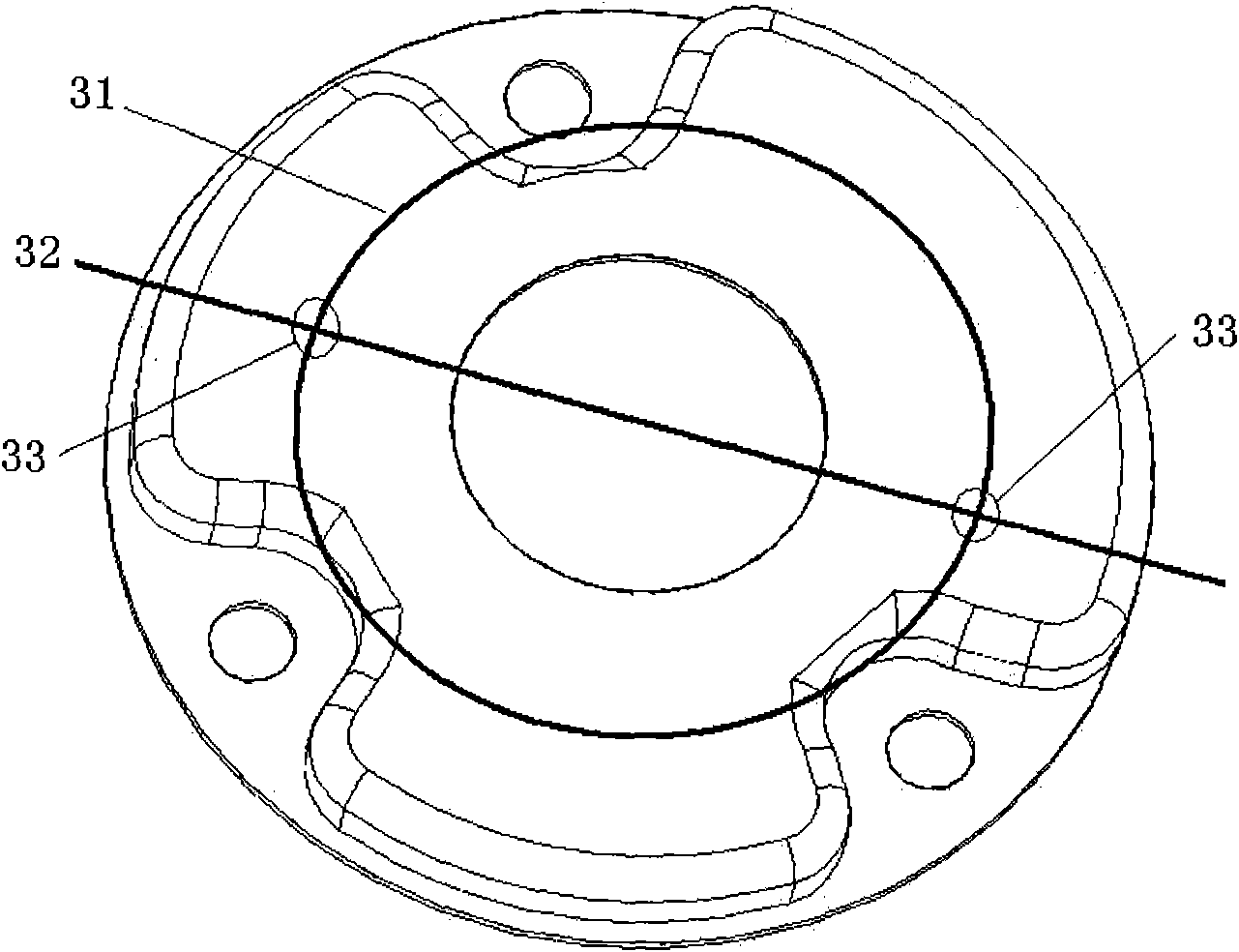

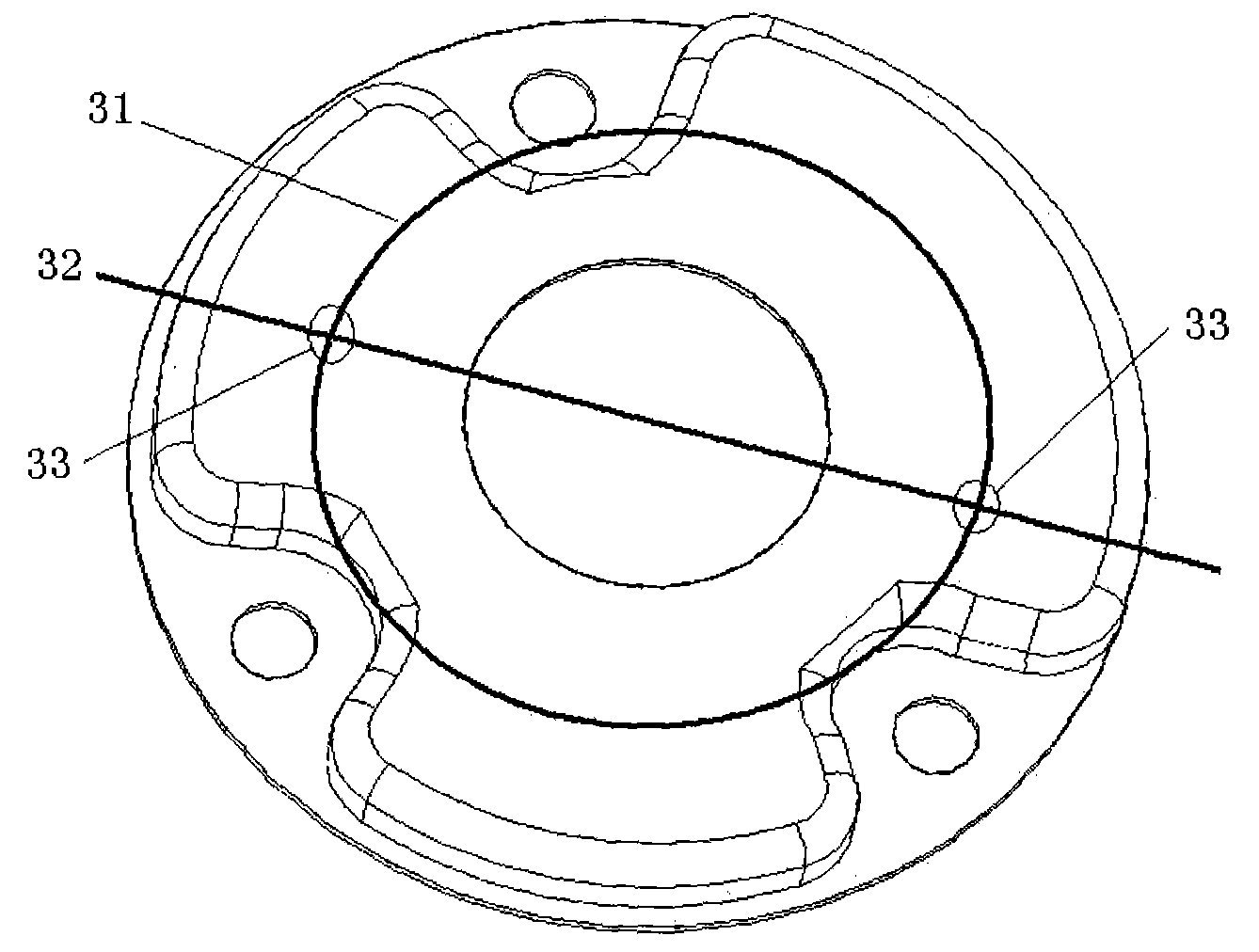

[0015] Such as Figure 1-2 As shown, a muffler that reduces the oil circulation rate of the compressor, the outlet position 33 of the muffler is arranged below the coil 22 of the motor stator 7, and the projection 31 of the coil center loop on the muffler is as follows figure 2 As shown, the refrigerant discharged from the muffler 3 is directly sprayed onto the coil 22. Due to the filtering (filter screen) function of the coil 22, the oil entrained in the refrigerant is difficult to continue to flow upward with the refrigerant, so it can fall back to the oil pool 21, so The amount of oil discharged from the compressor by the refrigerant is significantly reduced, resulting in a lower oil circulation rate.

[0016] Under the premise of ensuring that the outlet of the muffler 3 is aligned with the coil 22, the outlet of the muffler 3 is also located on the dipole acoustic mode node line 32 of the cavity in the lower part of the compressor housing, which can prevent the mode from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com