Explosion-proof type magnetic valve for mine

An explosion-proof, solenoid valve technology, applied in the field of solenoid valves, can solve the problems of easy eccentricity of the needle rod, easy valve damage, and poor valve closing life of the solenoid valve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

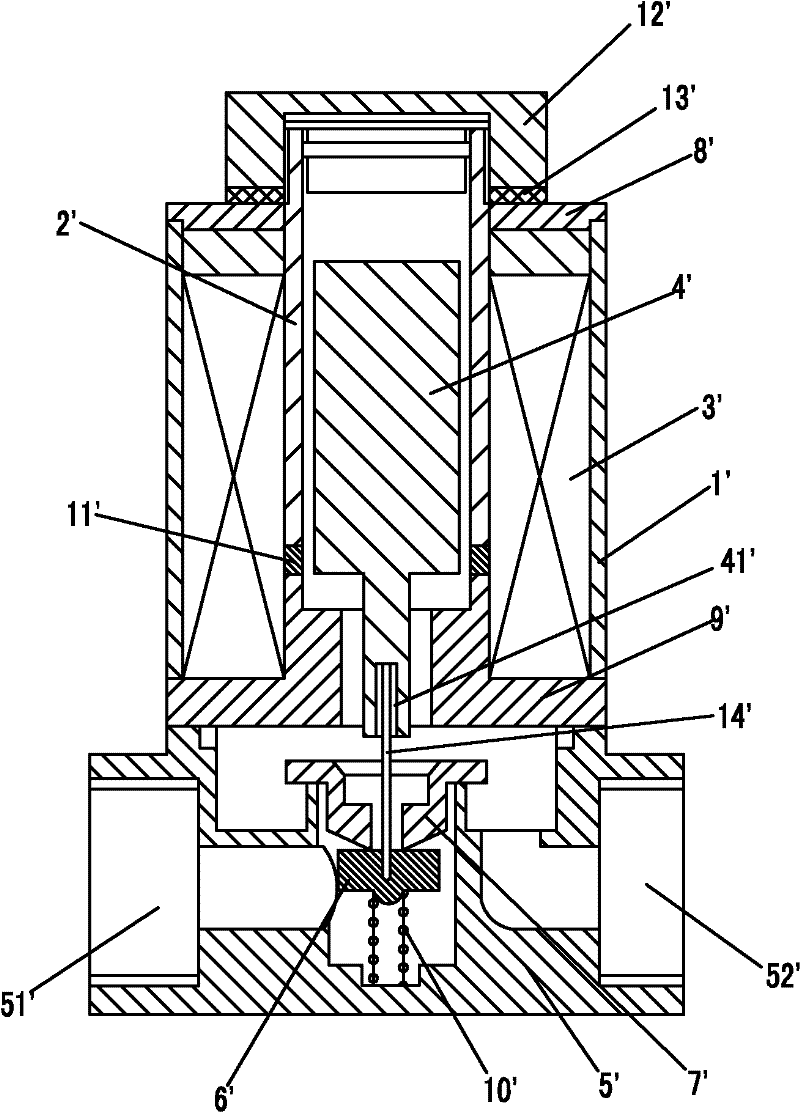

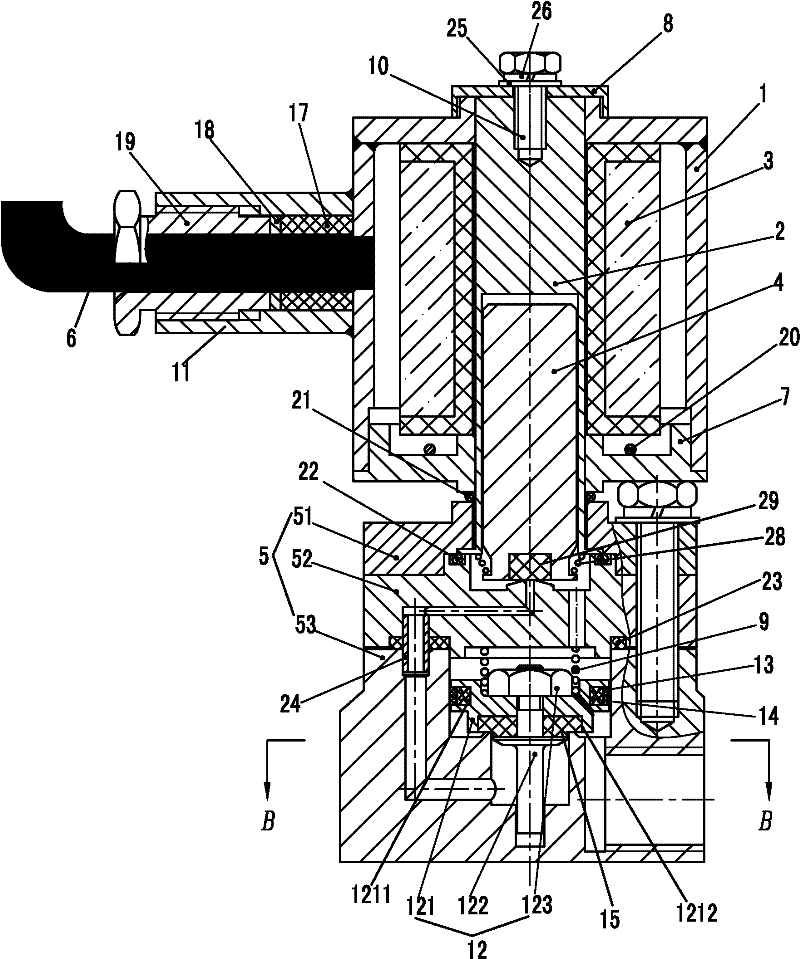

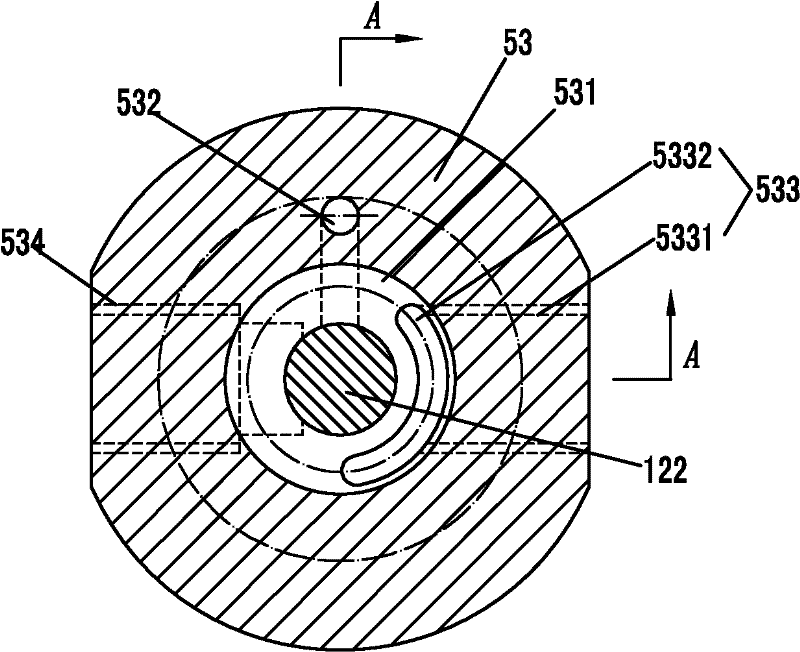

[0030] see figure 2 and image 3 As shown, the mine explosion-proof electromagnetic valve of the present invention includes an explosion-proof housing 1, a non-magnetic tube 2, an electromagnetic coil 3, a moving iron core 4, a valve body 5, a matching cable 6, an explosion-proof cover 7, a pressure pad 8, a compression Spring 9 and compression spring 12;

[0031] to combine figure 2 and Figure 4 As shown, the upper and lower sides of the explosion-proof housing 1 are open, and the front and rear walls of the outer surface of the explosion-proof housing 1 are provided with an arc-shaped reinforcing plate 27 that is fitted and fixed together;

[0032] The upper and lower ends of the explosion-proof shell 1 are respectively connected to the pressure pad 8 and the explosion-proof cover 7. The length of the flameproof joint surface between the explosion-proof shell 1 and the pressure pad 8 is greater than or equal to 6mm, and the flameproof gap is less than or equal to 0.2mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com