Measuring method for establishing equipment installation reference in stack pits

A technology of equipment installation and measurement method, applied in the direction of measuring device, line-of-sight measurement, measuring distance, etc., can solve the problems of instrument change measurement, unsatisfactory, error, etc., and achieve the effect of safe and reliable operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

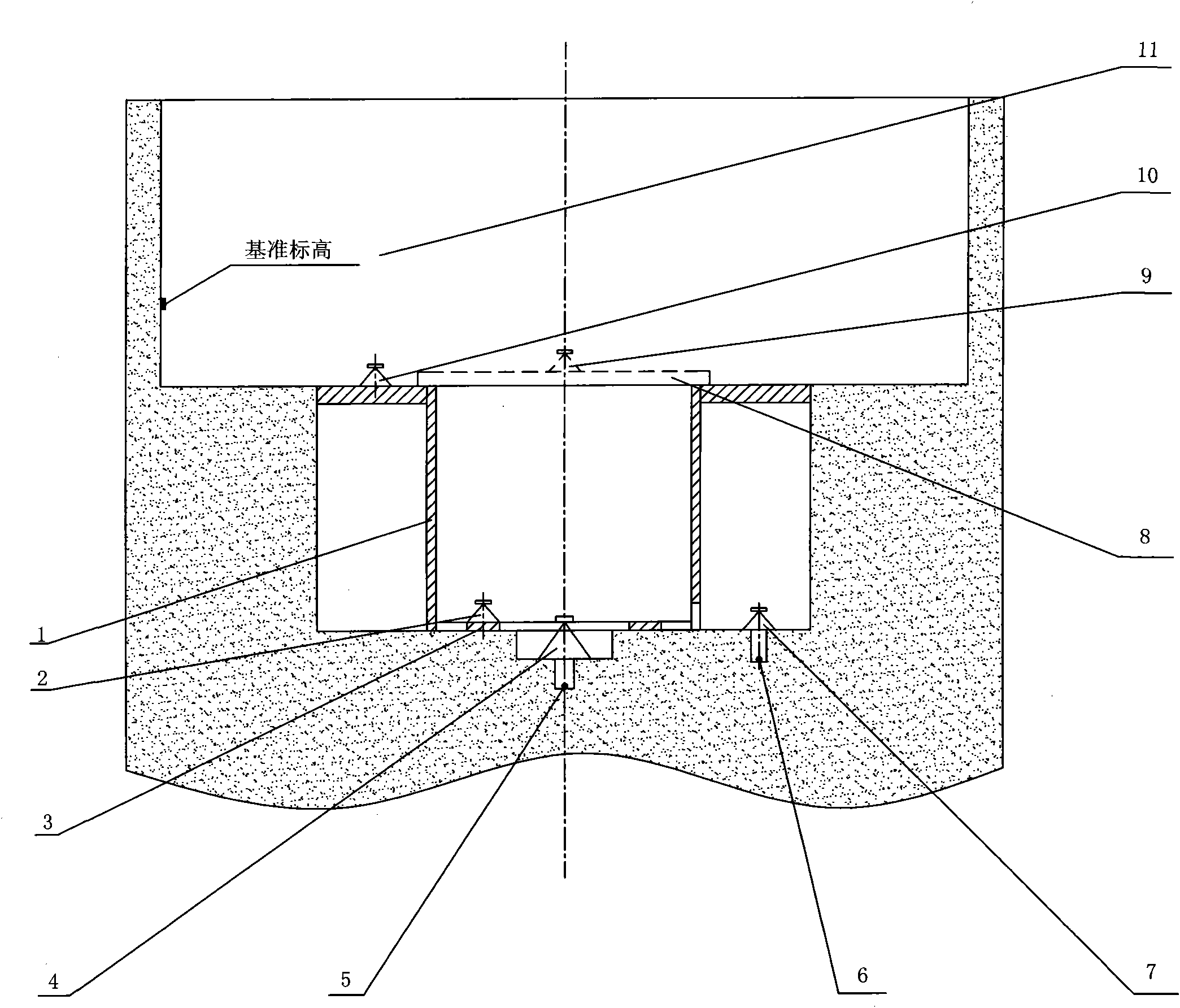

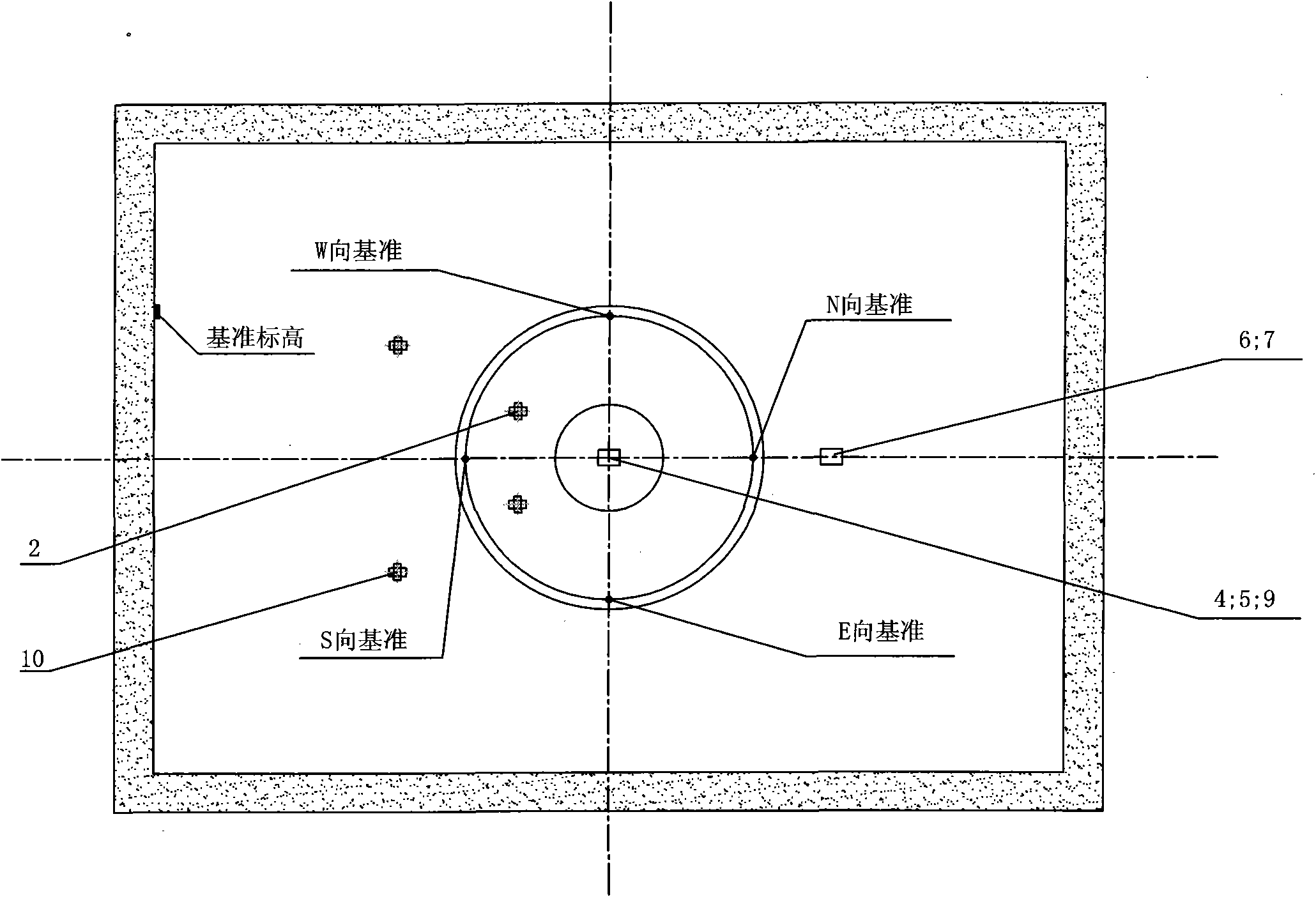

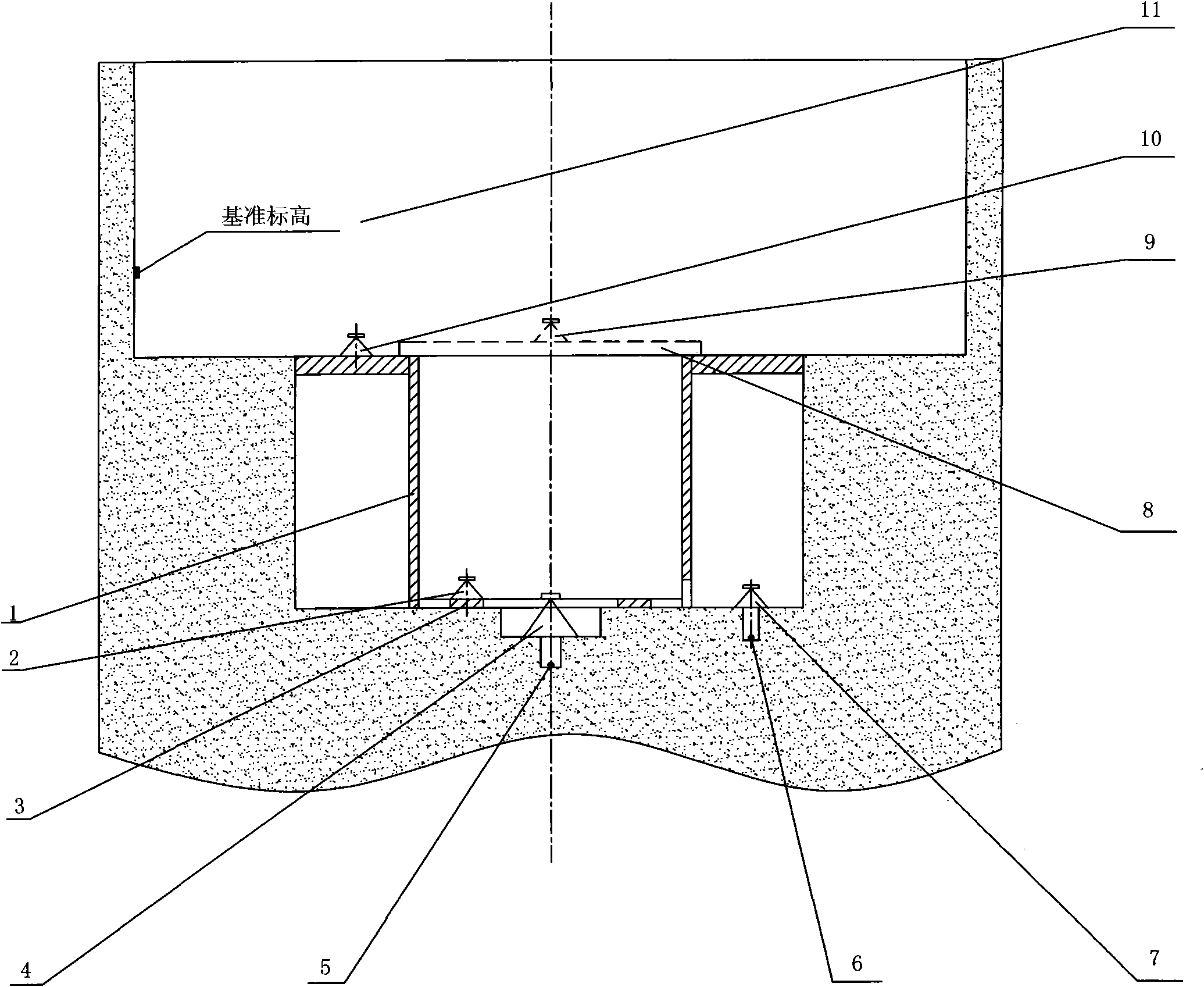

[0030] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-2 As shown in Fig. 1, a measurement method for establishing the installation datum of equipment in the pile pit, using an optical point-pointer, a precision level, and two precision electronic theodolites to form a measurement system to complete the transfer of the installation datum of stacking containers and other equipment, the specific measurement technical scheme includes the following steps :

[0031] A. At station B4 and station C7, use the optical point throwing instrument to accurately transfer the central reference point O5 of the pile pit 1 and the northward N reference point 6 to the corresponding visible positions on the ground, which are respectively recorded as reference points O' and N 下 ;

[0032] B. Precisely level the precision electronic theodolite at station B4 and align it with the reference point O', aiming at the north directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com