Traveling mechanism of robot on high voltage transmission line

A technology of high-voltage transmission lines and walking mechanisms, which is applied in the directions of manipulators, overhead lines/cable equipment, manufacturing tools, etc., to achieve the effects of stable center of gravity, good system stability, and strong ability to overcome obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

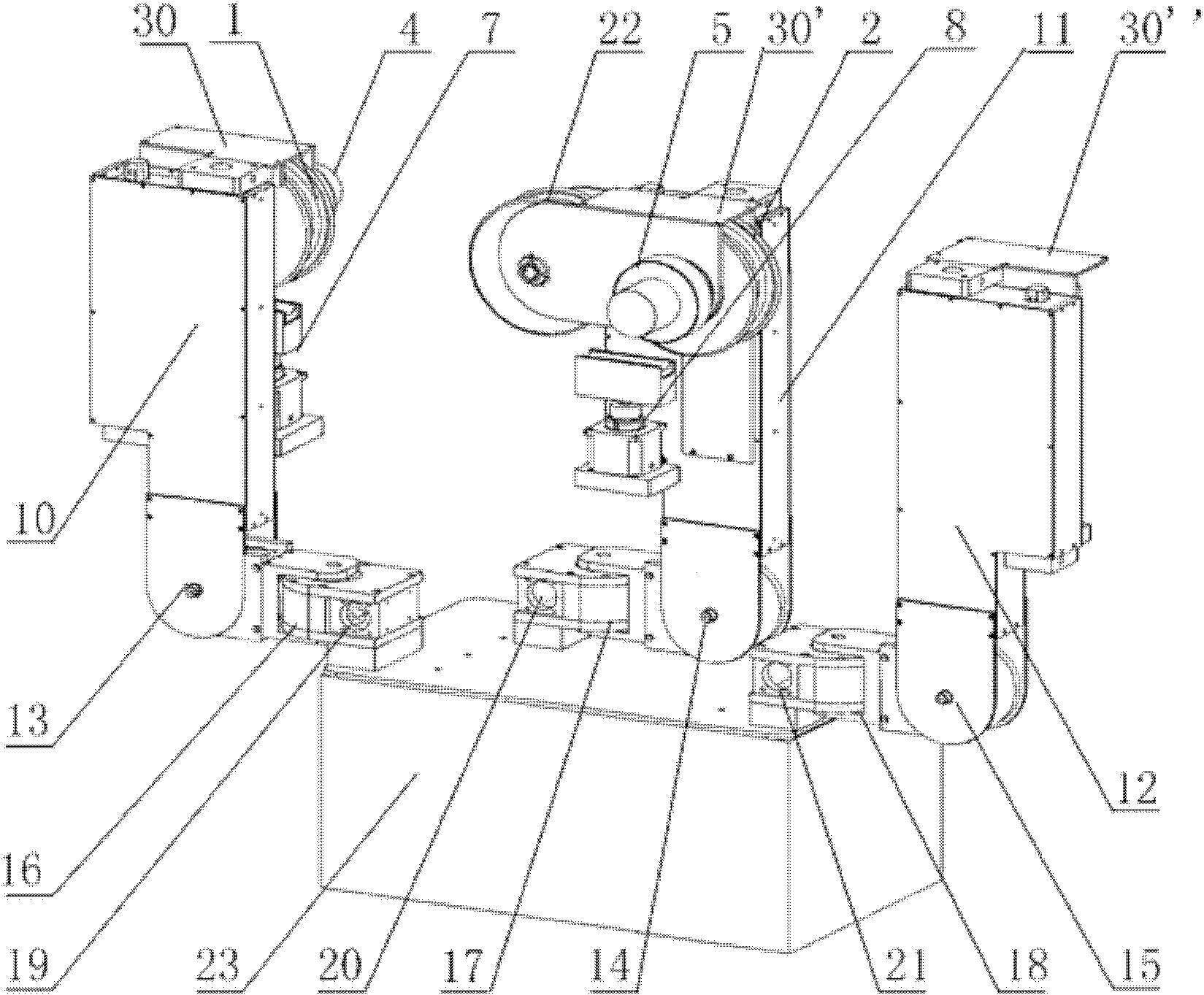

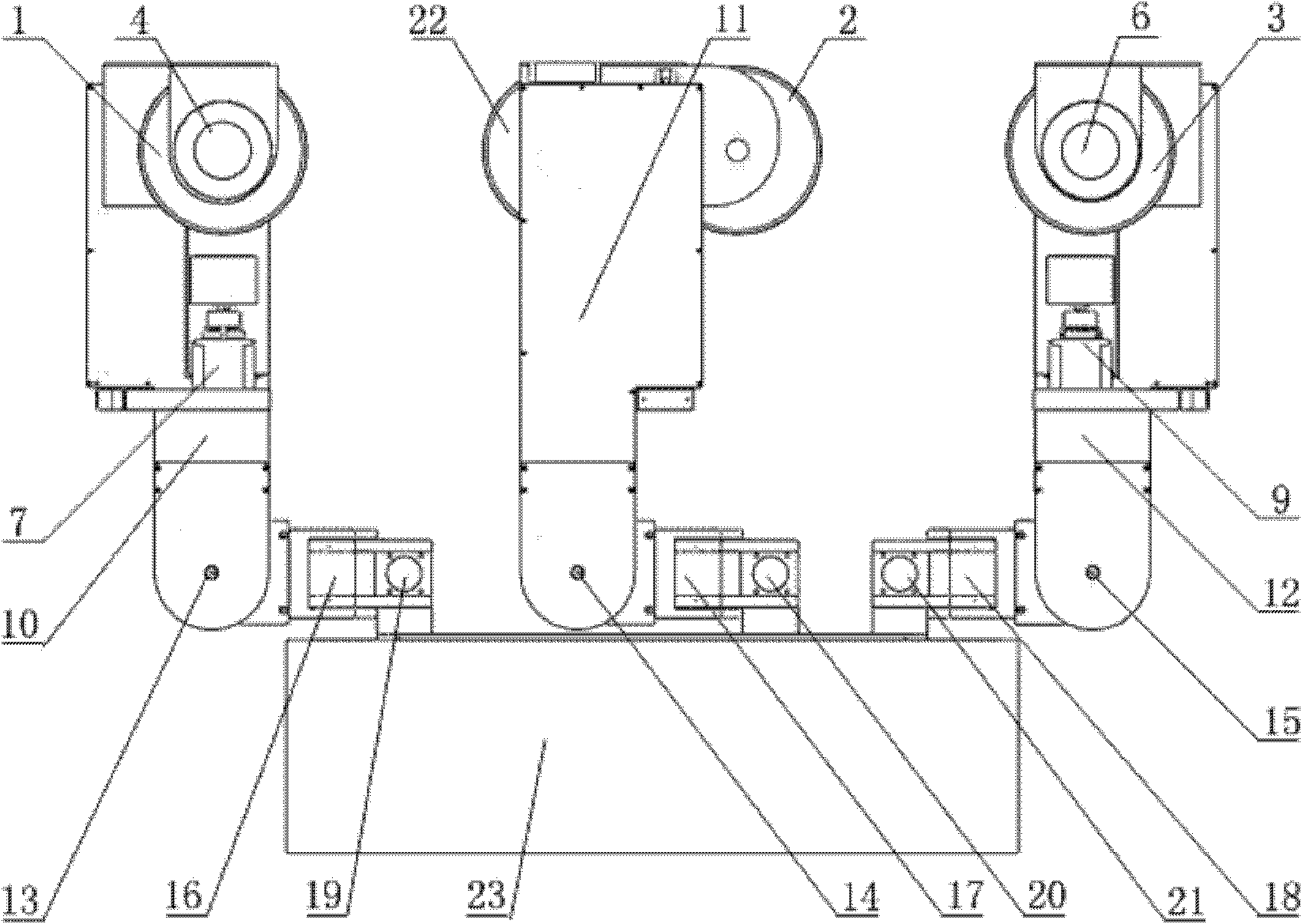

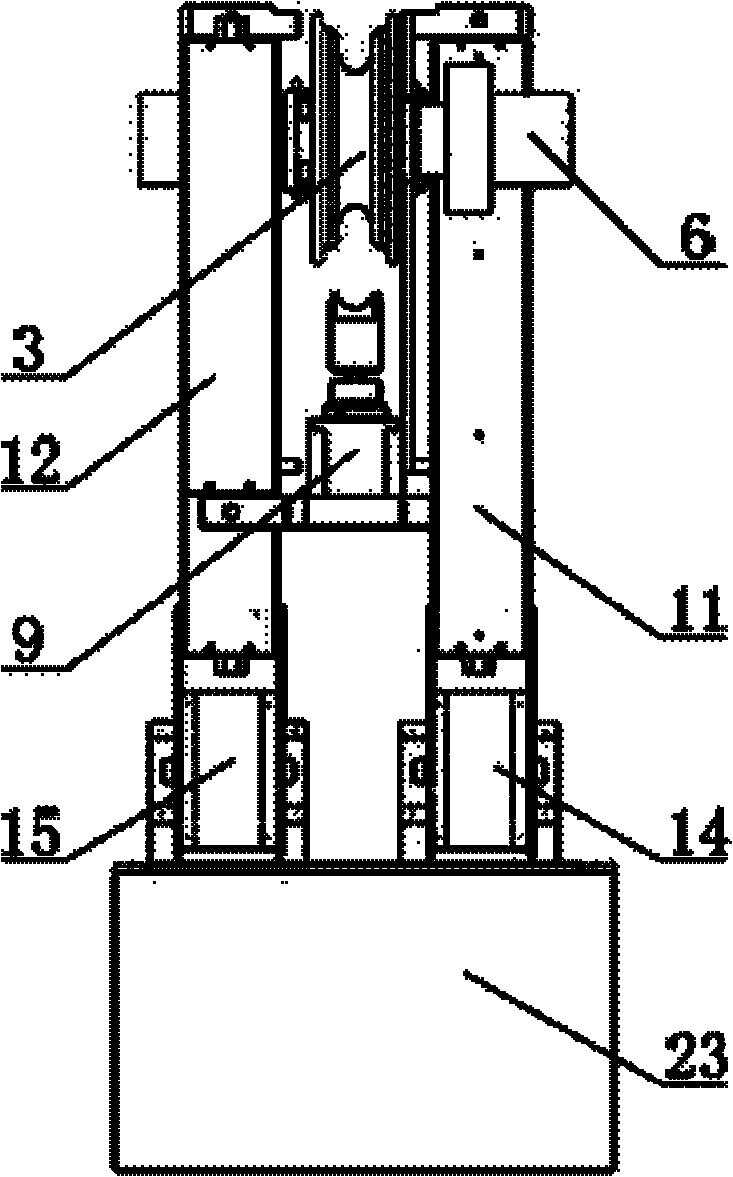

[0072] Such as figure 1 Shown is the three-dimensional schematic diagram of the overall structure of the barrier-crossing type high-voltage transmission line patrol and de-icing robot obstacle-crossing walking arm device of the present invention, figure 2 is the front view of the device, image 3 is a side view of the device, Figure 4 It is the top view of the device placed on the body control box. The barrier-crossing type high-voltage transmission line patrol line of the present invention, the obstacle-crossing walking arm device of the deicing robot comprises: 1, the forearm walking wheel 2, the middle arm walking wheel 3, the rear arm walking wheel 4, the forearm walking drive motor 5, the middle arm Walking drive motor 6, rear arm walking drive motor 7, forearm brake mechanism 8, middle arm brake mechanism 9, rear arm brake mechanism 10, forearm lifting arm 11, middle arm lifting arm 12, rear arm lifting arm 13, forearm soft joint 14 , middle arm soft joint 15, rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com