Dust collector with dust compression function

A dust collector and dust technology, applied in vacuum cleaners, household appliances, cleaning equipment, etc., can solve the problems of dust affecting installation, inhaling fine dust, inconvenience to users, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0026] The working principle of the vacuum cleaner of the present invention is the same as that of the prior art, and the prior art can be referred to, so it will not be described again, and the same symbols as those of the prior art will be used. The differences between the present invention and the prior art will be described below Detailed explanation:

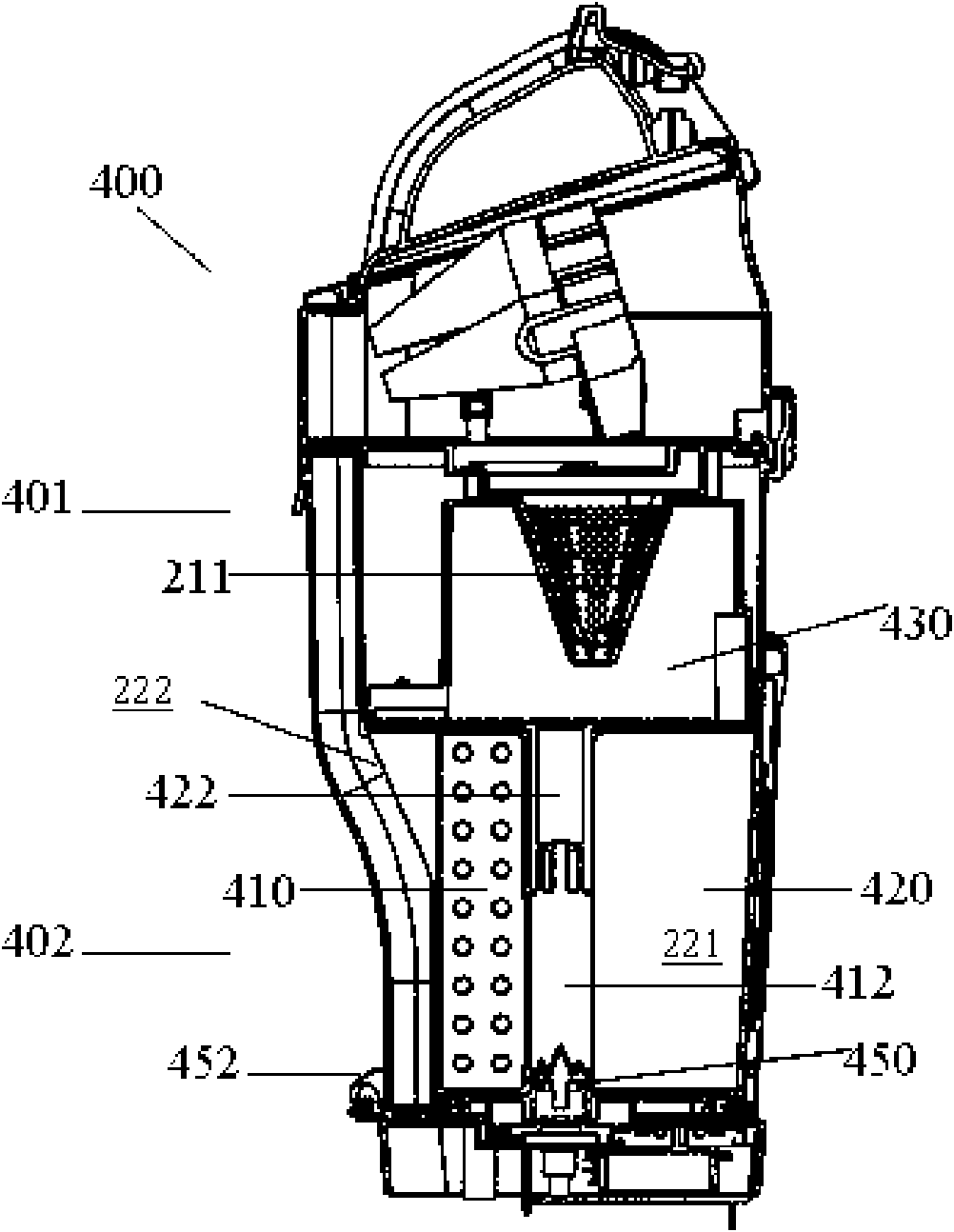

[0027] Such as image 3 As shown, the dust collecting bucket 202 includes a pair of pressing plates 410 and 420 , wherein the rotating compressing piece 410 is rotatably disposed in the dust collecting bucket 402 , and the fixed compressing piece 420 is fixed in the dust collecting bucket 402 . The upper end of the fixed compression piece 420 is fixedly connected with the lower surface of the partition plate 230 , and integrally formed with the stationary shaft 422 coaxial with the axis of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com