Steam sprayer

A sprayer and steam technology, which is applied in the direction of atomizers, bathing devices, physical therapy, etc. for treatment, can solve the problems of sprayer burst, user injury, and high cost, so as to improve the safety of use and reduce the placement of Space, the effect of reducing packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

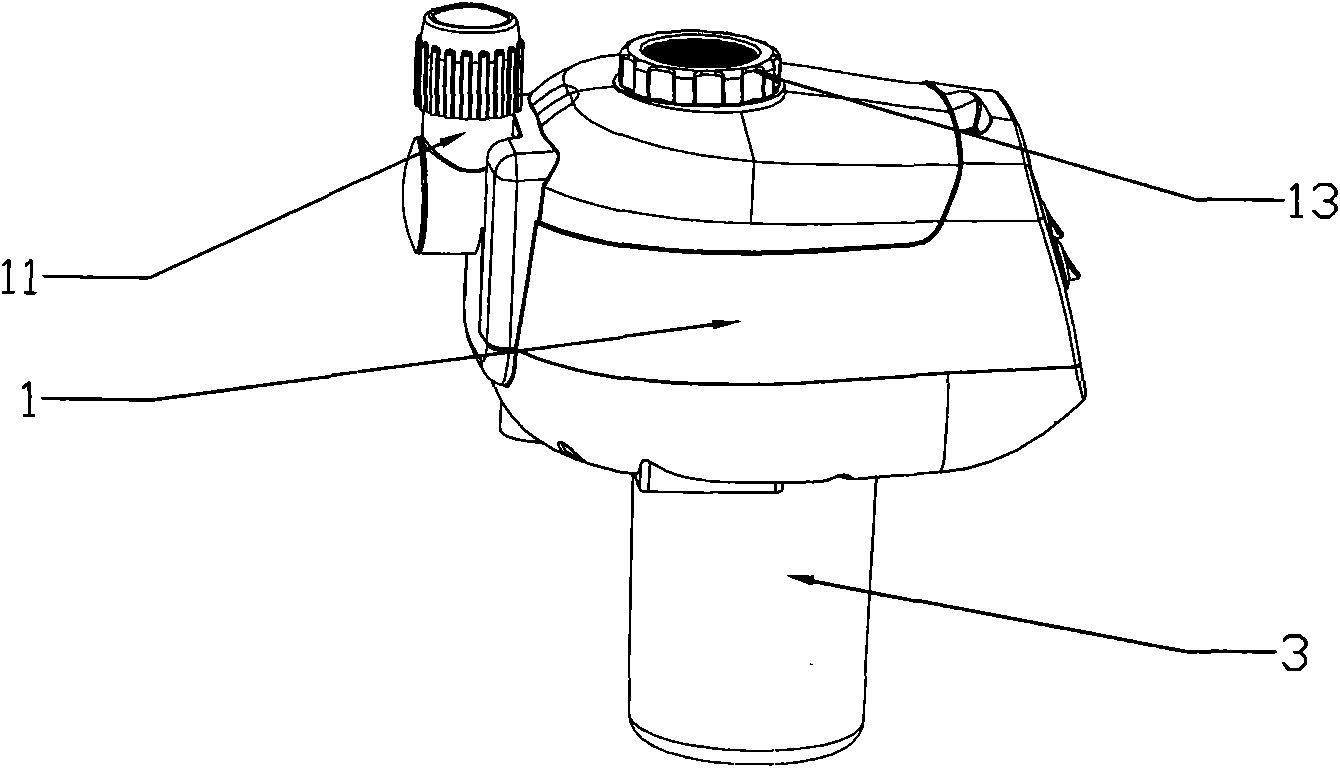

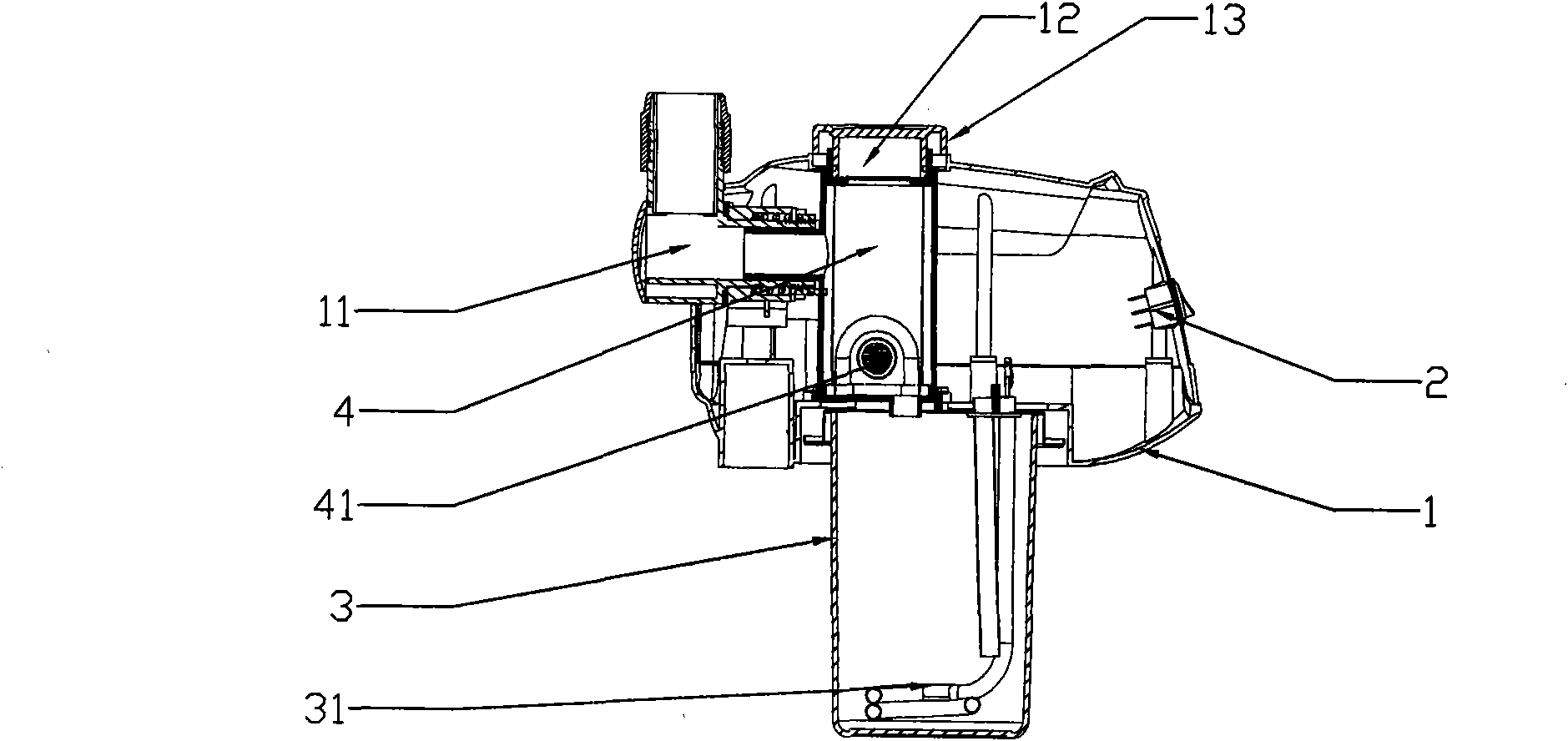

[0017] Such as figure 1 , figure 2 As shown, the present invention includes a housing 1, the housing 1 is provided with a spray port 11, the inside of the housing 1 is provided with a control panel 2, a kettle 3, and the control panel 2 is provided with several control switches, The water pot 3 is provided with a heating wire 31, and the heating wire 31 is electrically connected to the control board 2. The water pot 4 is filled with water, which is heated by the heating wire 31 to generate water vapor. 1 is also provided with an air duct 4, the air duct 4 communicates with the kettle 3 and the spray port 11 respectively, and the side wall of the air duct 4 is provided with a spray fan 41, and the spray fan 41 is connected to the spray port 11. The control board 2 is electrically connected. During use, the heating wire 31 and the spray fan 41 in the water pot 3 are energized through the control board 2, and the heating wire 31 in the water pot 3 is first controlled by the co...

Embodiment 2

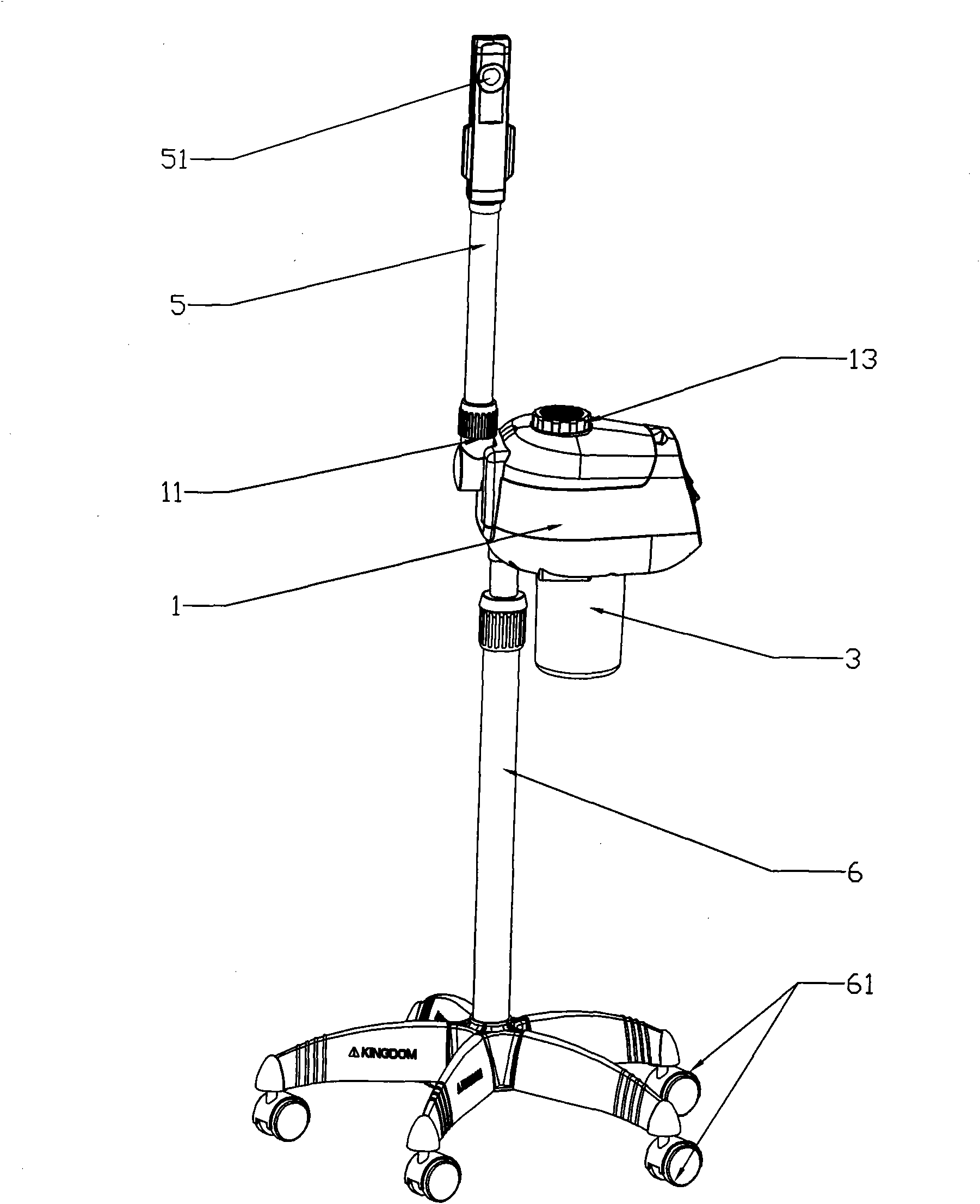

[0019] Such as image 3 , Figure 4 , Figure 5 As shown, compared with Embodiment 1, this embodiment also includes a spray tube 5, one end of the spray tube 5 is rotatably engaged with the spray port 11, and the other end of the spray tube 5 is provided with a spray head 51, The spray pipe 5 is detachably matched with the spray port 11 of the housing 1. When the sprayer needs to be used at a relatively long distance, the spray pipe 5 can be installed for use. When in use, the air duct 4 The mist in the interior is pushed by the spray fan 41 and enters the inside of the spray pipe 5 from the spray port 11, and then sprays out from the spray head 51 of the spray pipe 5, and the spray pipe 5 can also be in contact with the spray The matching part of the mouth 11 is rotated to select a suitable angle for use, which is convenient and flexible; as in the short-distance use or non-use state, the spray pipe 5 can be removed to reduce the occupied space and facilitate placement.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com