Automatically covering/uncovering system of steel ladle

A technology for adding lids and ladle lids, applied in metal processing equipment, lighting and heating equipment, furnace types, etc., can solve the problems of high manufacturing cost, high error rate, and many parts, and achieve compact structure and high reliability. , cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

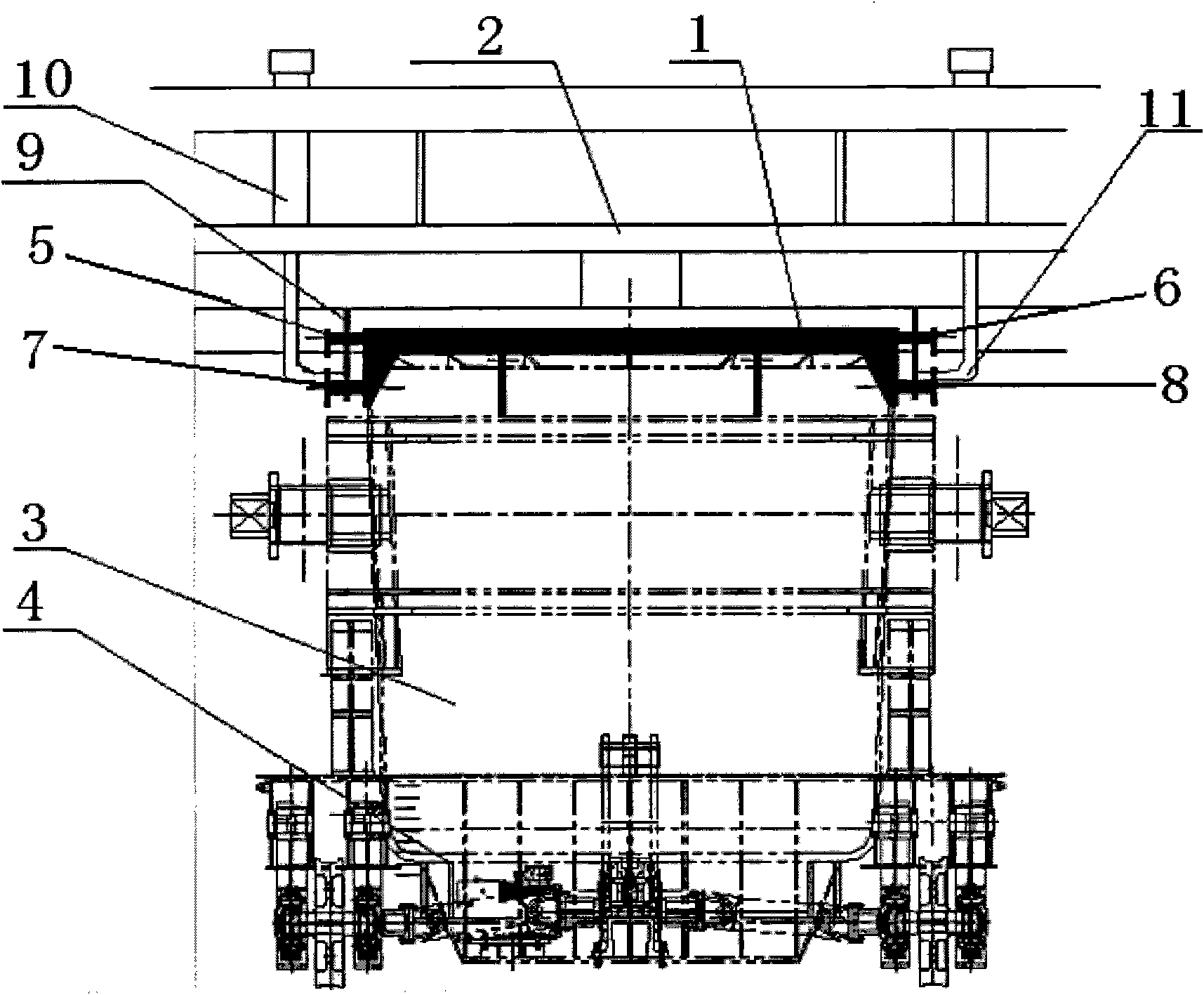

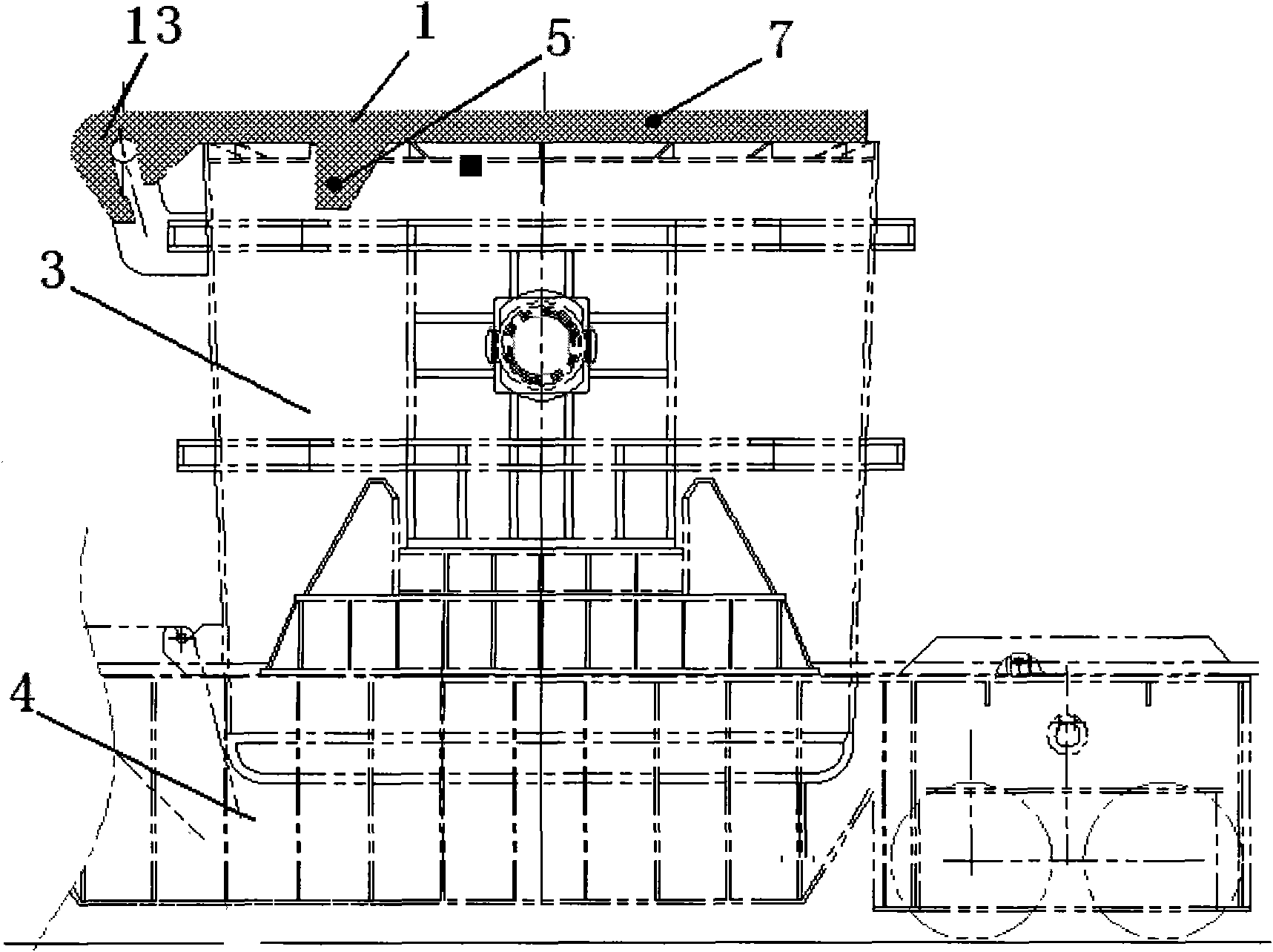

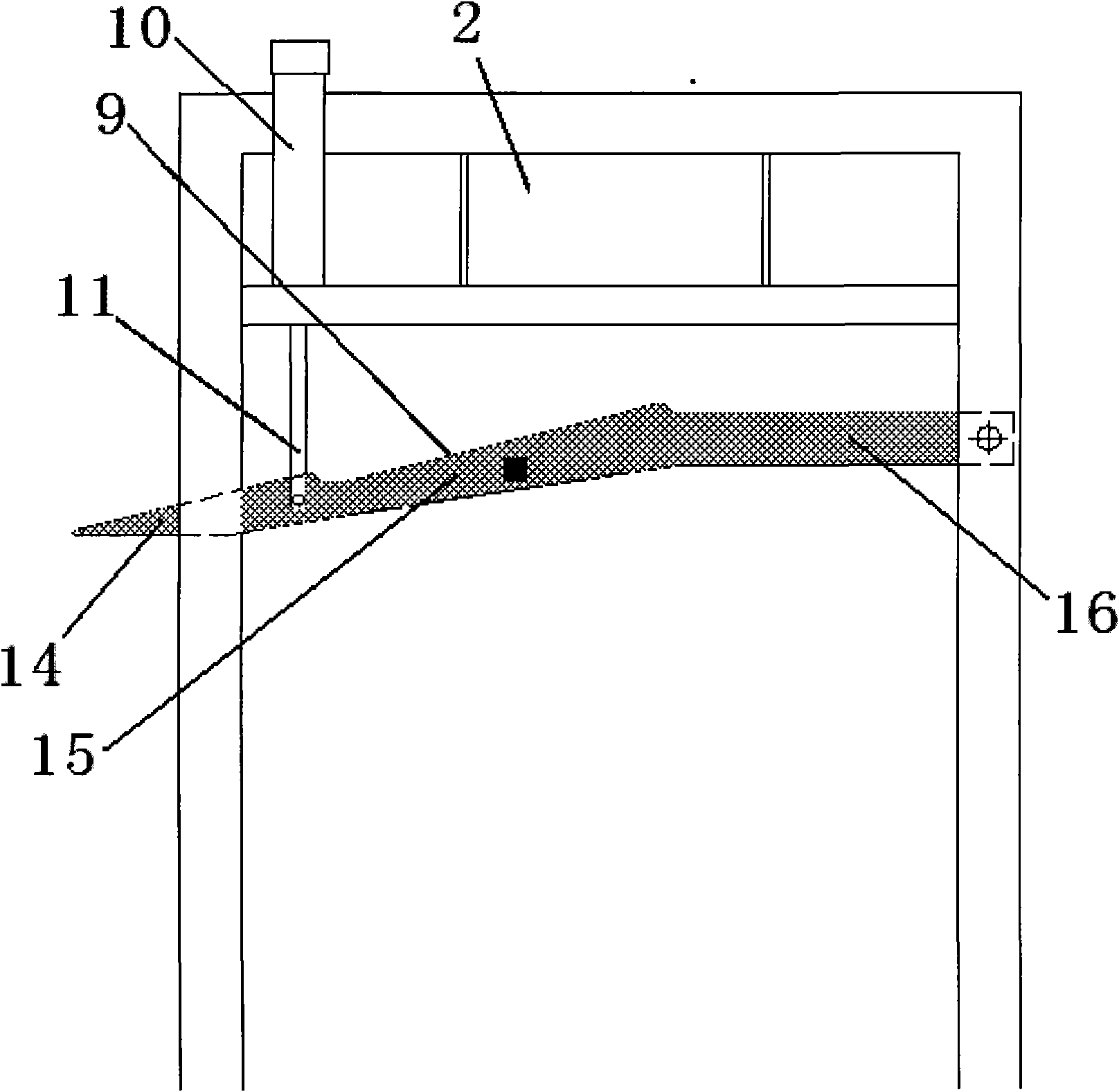

[0035] Such as Figure 1-8 As shown, the technical solution provided by the present invention is an automatic ladle capping system, comprising a ladle cap 1 and a ladle capping mechanism 2, the ladle cap 1 is provided with a trunnion, and the trunnion arrangement position In the direction in which the main body of the ladle cover 1 extends outward, the trunnions are in contact with the ladle cover removing mechanism 2 during the process of removing the cover. The trunnion is arranged on the side surface of the ladle cover 1 . The trunnions include a first trunnion 5, a second trunnion 6, a third trunnion 7, and a fourth trunnion 8, the first trunnion 5 and the third trunnion 7 are arranged on the same side, the The second trunnion 6 and the fourth trunnion 8 are arranged on the same side; the first trunnion 5 is arranged symmetrically to the second trunnion 6 , and the third trunnion 7 is arranged symmetrically to the fourth trunnion 8 . The first trunnion 5 is on the same l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com