Land and air double-used aircraft

A dual-use technology for land and air, aircraft, applied to aircraft, vertical take-off and landing aircraft, vehicles that can be converted into aircraft, etc., can solve the problems of large vibration and noise, large volume and weight of aircraft, and achieve the effect of overcoming dead weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

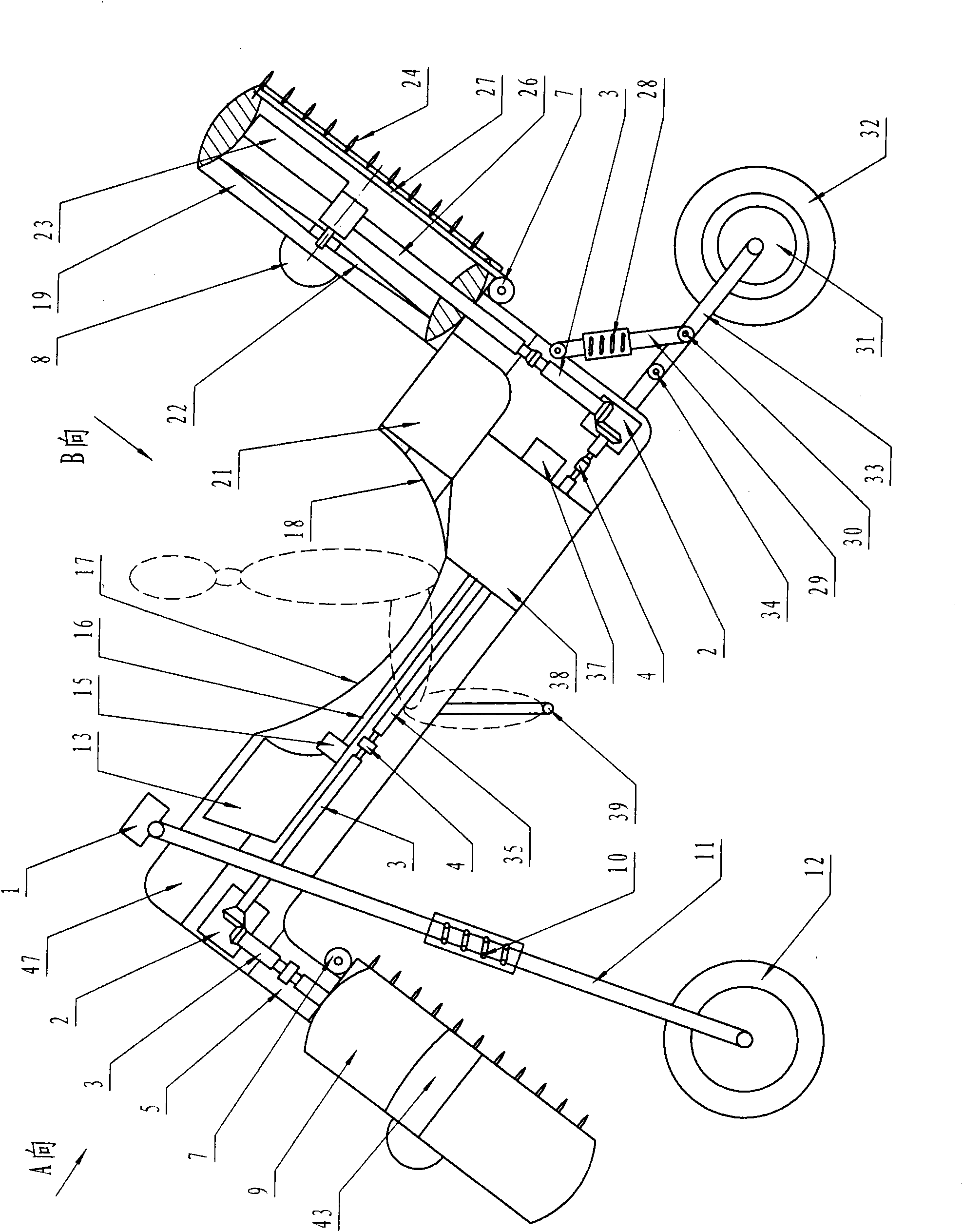

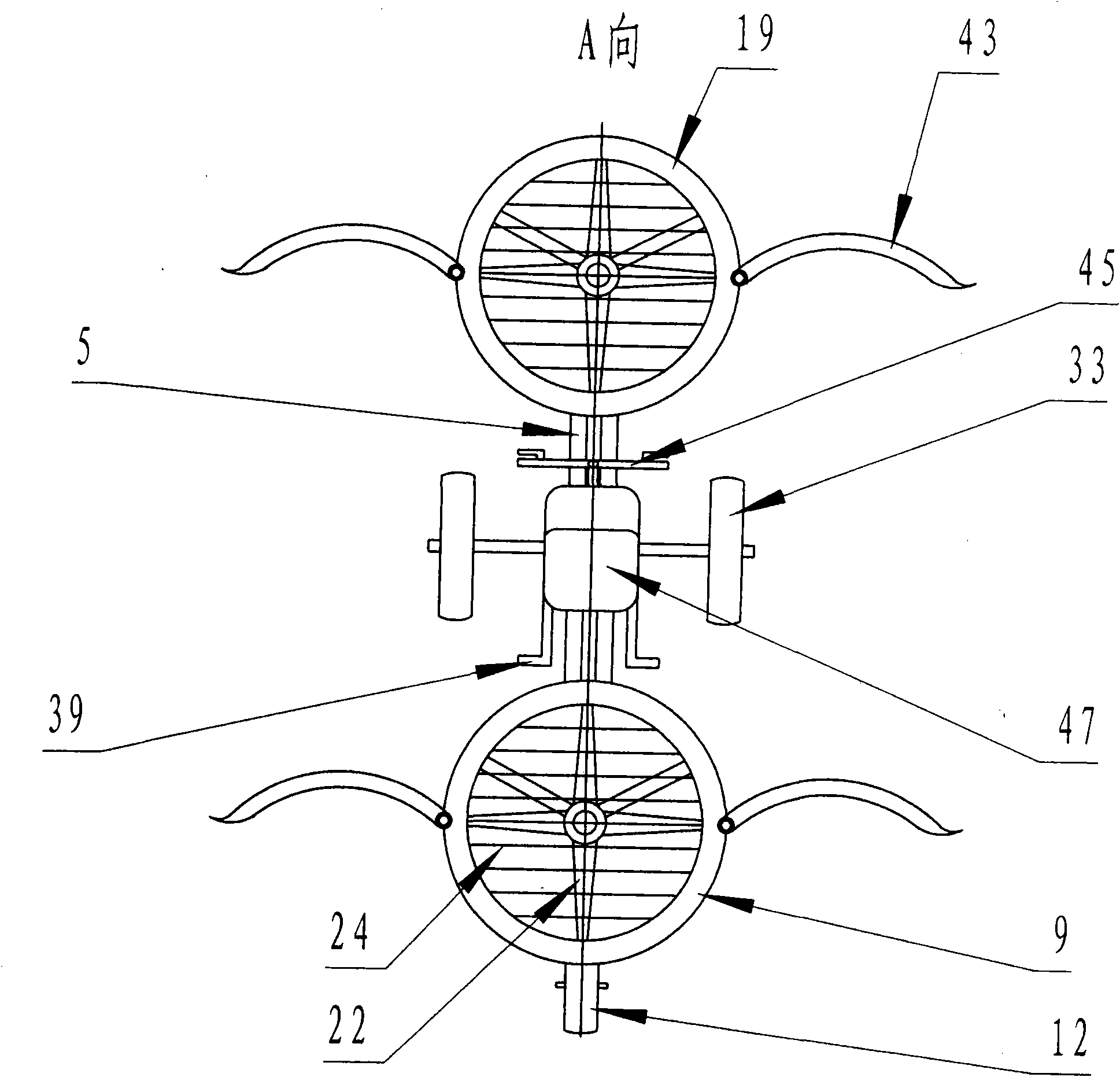

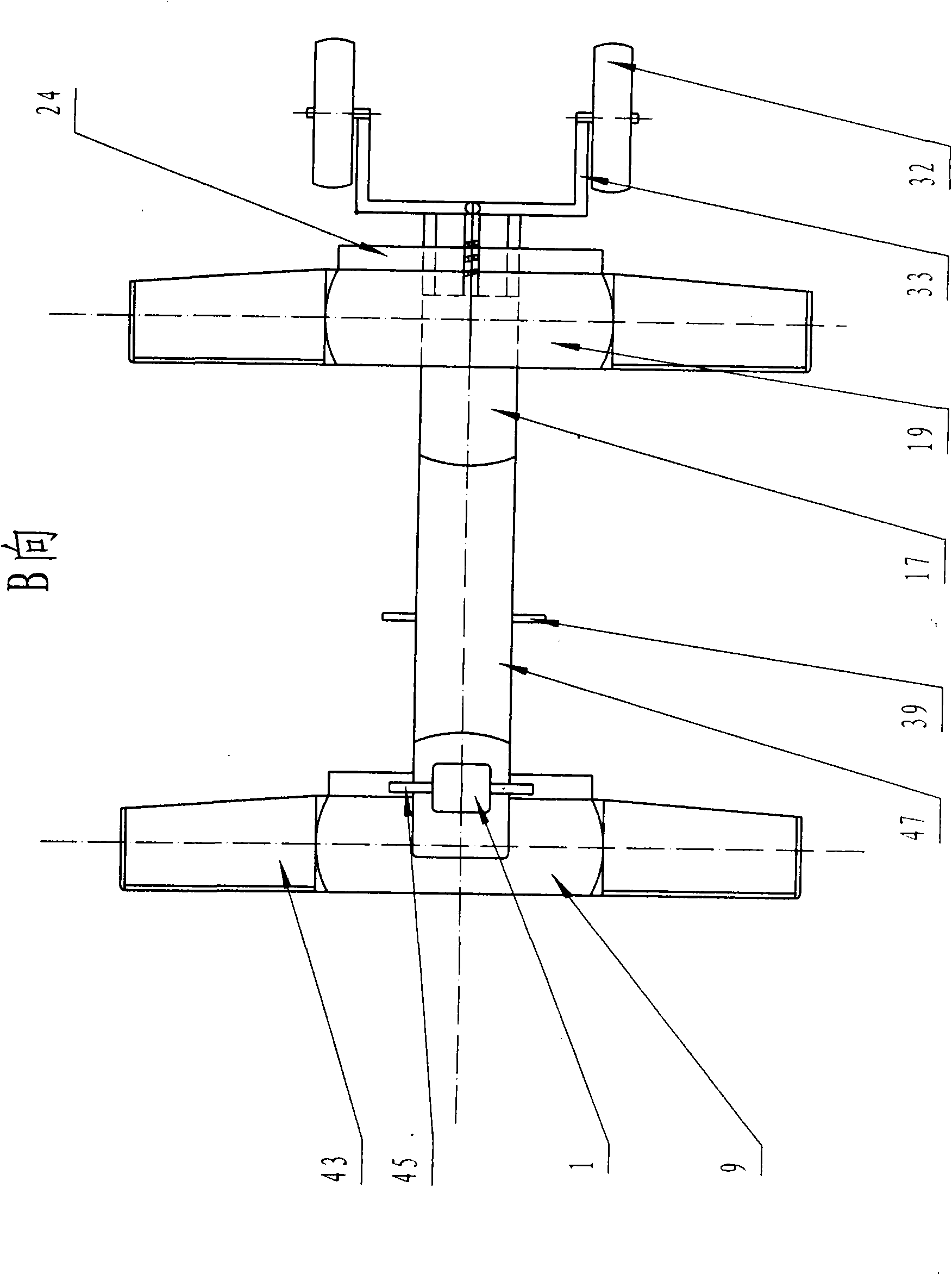

[0031] Such as Figure 1-Figure 3 As shown, a kind of basic structural form of this ground-air dual-purpose aircraft is that the front and rear ends of the body 47 are respectively connected with the pipeline girder 5 that is perpendicular to the body and protrudes downwards and upwards respectively, and the pipeline girder 5 at the front end of the body 47 The lower end of the 5 is connected with a front ducted fan 9; the upper end of the pipeline girder 5 at the rear end of the body 47 is connected with a rear ducted fan 19. The axis lines of the propellers in the front and rear ducted fans are kept parallel to the axis lines of the body 47 respectively. Certainly, the included angle of pipeline girder 5 and body 47 also can change slightly, or the axis line of front and rear duct fan and the axis line of body 47 keep a very small angle, but front and rear duct The fans are preferably kept in a column opposite to the front and rear ( image 3 ). In short, the windward sid...

Embodiment 2

[0048] Such as Figure 5 As shown, the basic structure of the present embodiment is the same as that of Embodiment 1, except that the rear ducted fan 19 is changed into two side by side, and only the front ducted fan 9 is provided with a folding wing 43, and the rear ducted fan 19 Not only the wings are established, but the tops of the two rear ducted fans 19 are connected with reinforcing plates 40, and the ducts of the reinforcing plates and the rear ducted fans are used as quasi-wings. Two rear ducted fans 19 arranged side by side are supported and connected by two pipe girders 5 and transmit power. The two pipeline girders 5 are arranged in a V shape, and both are vertically connected with the body 47 .

Embodiment 3

[0050] Such as Figure 6 As shown, the basic structure of this embodiment is the same as that of Embodiment 1, and the rear ducted fans 19 are also two side by side. Foldable wings 43 are arranged on both sides of the duct of the front ducted fan 9, and no reinforcing plate is established between the two rear ducted fans 19, but are respectively arranged on the outer end sides of the two rear ducted fans. A wing 43. The two rear ducted fans 19 are respectively arranged at both ends of the transverse transmission shaft tube 50 , and the transverse transmission shaft tube 50 is connected to the upper end of the pipeline girder 5 through a tilting mechanism 51 . In this way, the two rear ducted fans 19 can be tilted at a certain angle by the rotation of the transverse transmission shaft tube 50, forming a power (ducted fan) tilting structure.

[0051] In this embodiment, a fixed connection mechanism is also provided at the position of the tilting mechanism 51 so that the two re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com