Automatic track exchanging trolley

A trolley and automatic technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of many consumables, long running routes, occupying space, etc., to improve work efficiency, large rail change angle, and production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

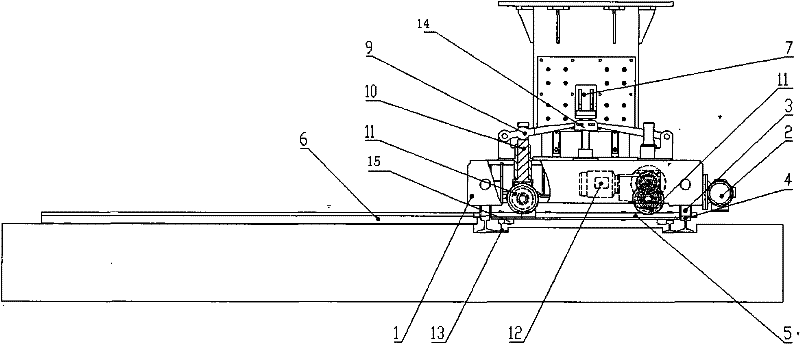

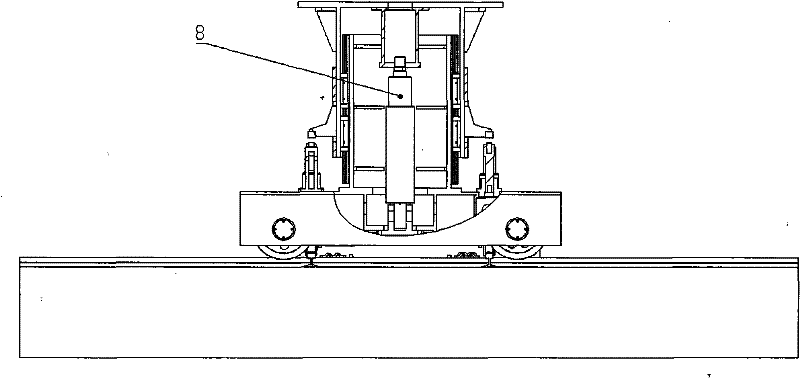

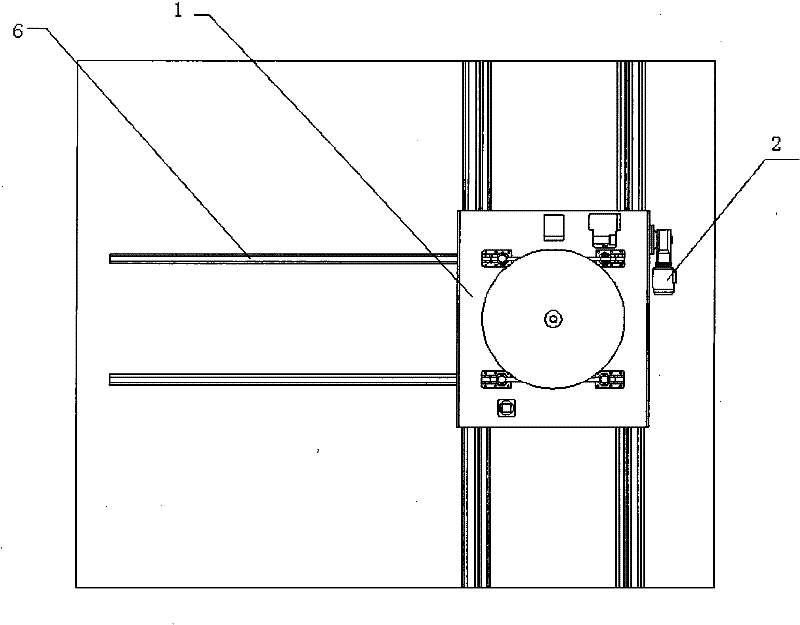

[0019] figure 1 It is a front view of an embodiment of the present invention; figure 2 It is a side view of an embodiment of the present invention; image 3 It is a top view of an embodiment of the present invention.

[0020] Such as Figure 1 to Figure 3 Shown: automatic track-changing trolley, including trolley frame 1, track, traveling wheel and driving device, wherein traveling wheel and driving device are all arranged on trolley frame 1, and described track is divided into main track 4, moving auxiliary track 5 and Secondary track 6, wherein, mobile secondary track 5 is vertically arranged on two main tracks 4, and its two ends are snapped on two main tracks 4 respectively, and secondary track 6 is also vertically arranged with two main tracks 4, and it is connected with mobile secondary track 4. The rail 5 is on the same level, and the traveling wheels include the main track roller 3 walking on the main track 4 and the secondary track roller 11 walking on the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com