Maintenance method for blast furnace hearth

A blast furnace and cooling stave technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as the impact of blast furnace life, and achieve the effects of low cost, simple construction process, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0014] A maintenance method for a blast furnace hearth. The specific maintenance steps are as follows:

[0015] Step 1: Collect and summarize data. Monitor and measure the temperature difference between the temperature measured by each thermocouple installed in the hearth area of the blast furnace and the water temperature difference of the stave 2, collect the monitored and measured data and organize and summarize; when the summarized data shows that the thermocouple somewhere When the measured temperature rises sharply and the change value of the water temperature difference of the corresponding stave 2 is less than 1°, it indicates that there is a gap in the carbon ramming material between the carbon brick and the stave 2, forming a heat insulation layer;

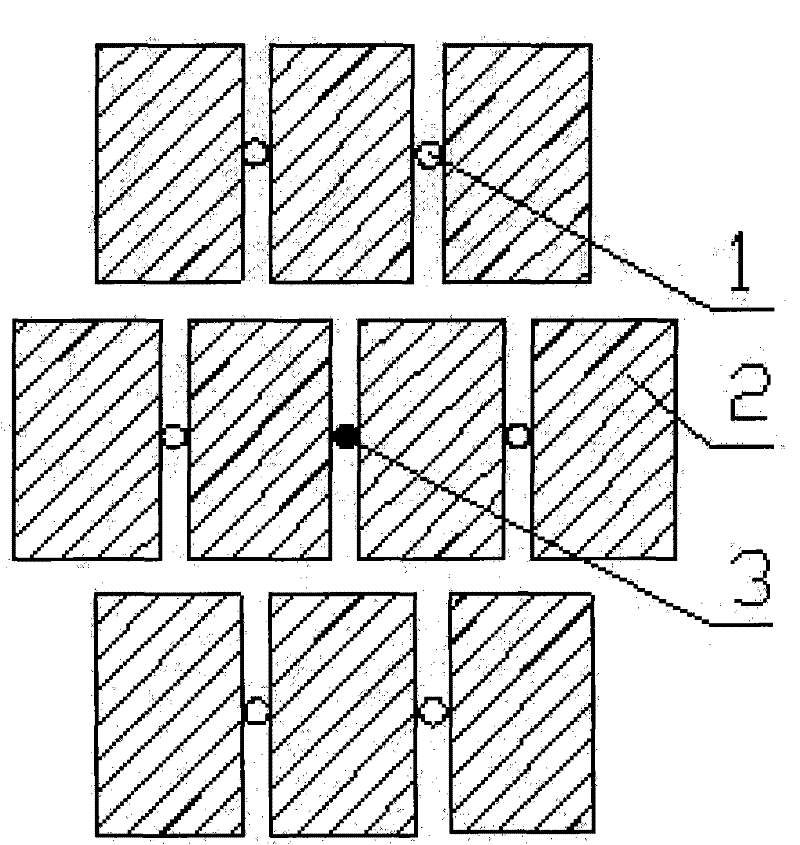

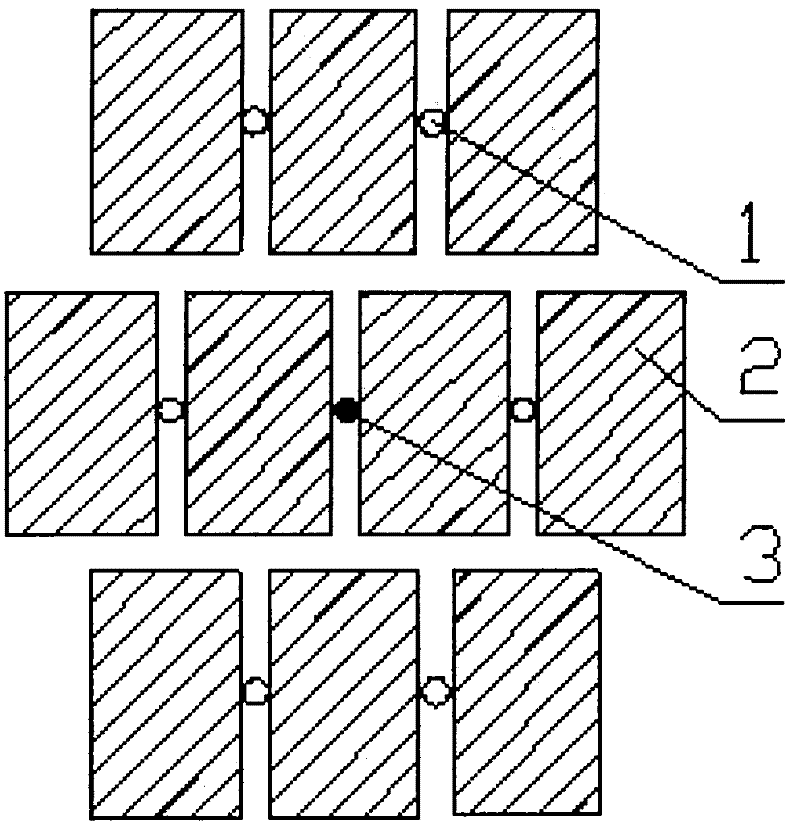

[0016] Step 2: Determine the location of the grouting hole 1. Such as figure 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com