Heat insulating cage and ingot casting furnace with same

A heat insulation cage and ingot furnace technology, applied in the field of ingot furnaces, can solve problems such as low heat reflectivity and heat waste, and achieve the effects of improving heat reflectivity, reducing production costs, and reducing thermal power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

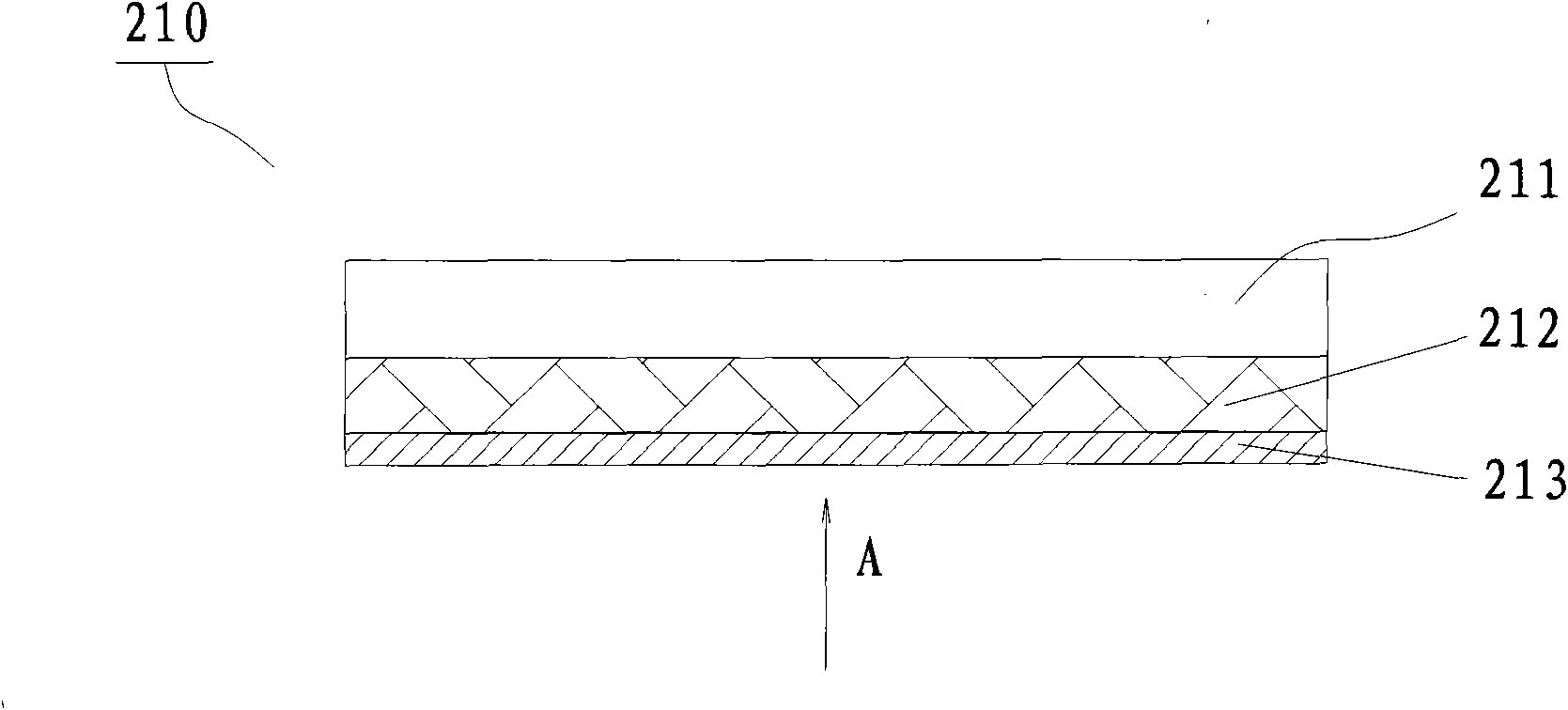

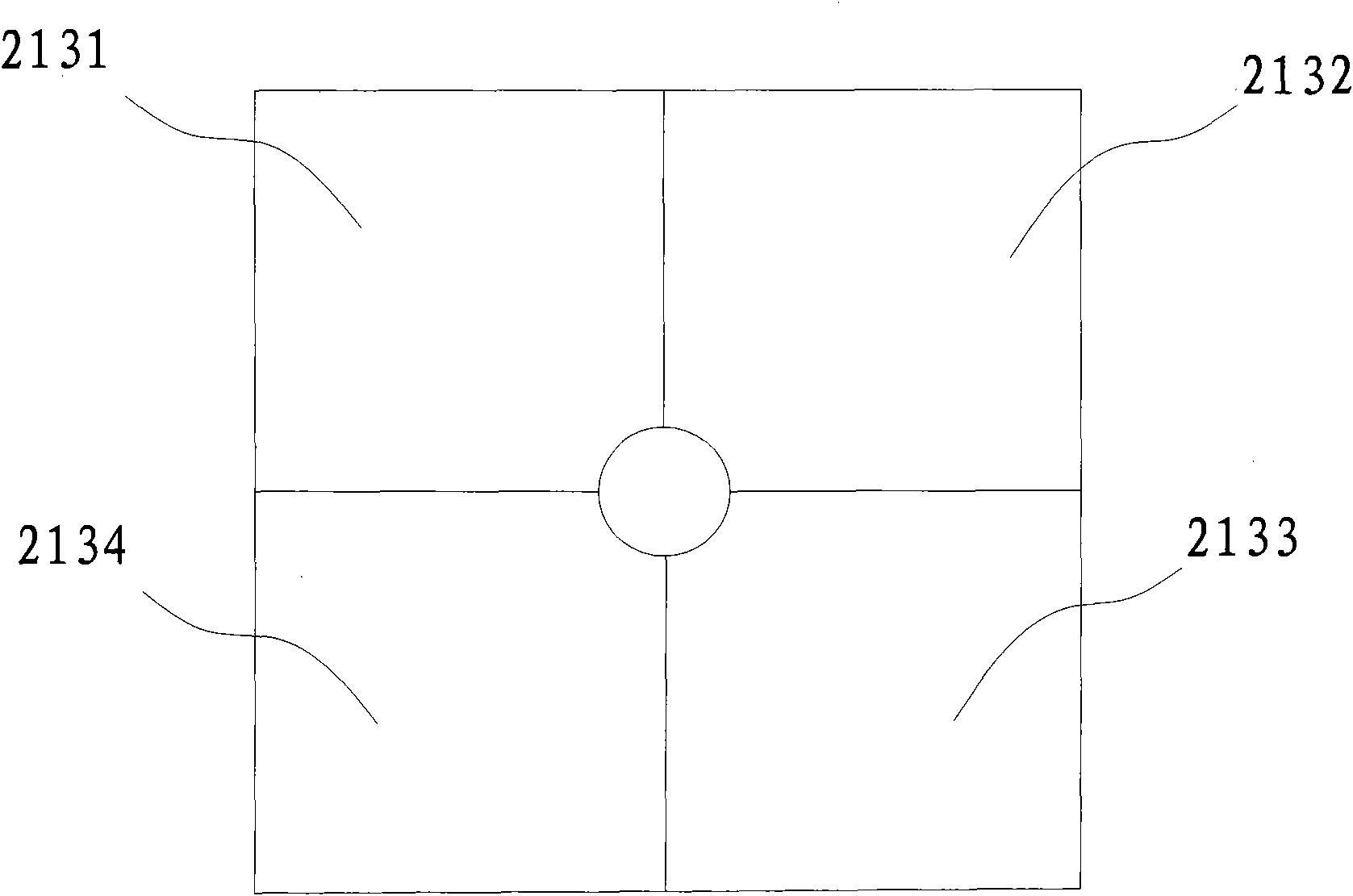

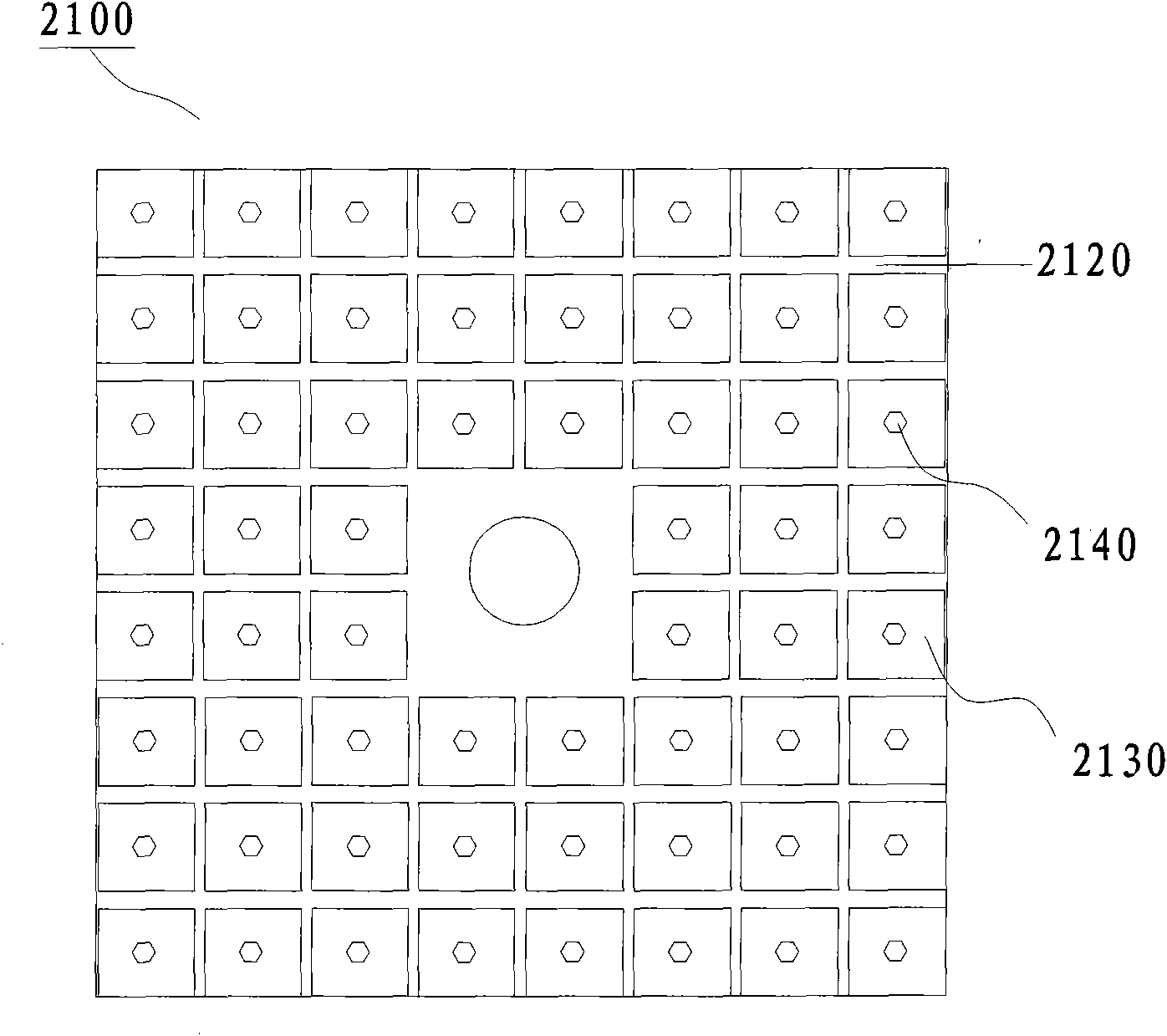

[0024] The heat insulation cage usually used for polycrystalline furnaces includes a top plate and a side plate. The top plate is composed of a carbon-carbon composite material matrix and an insulation layer. The insulation layer can be located inside or outside the matrix; the side plate is mainly composed of The insulation layer is formed, of course, the side panels can also have a multi-layer structure, for example, they can have the same structure as the top panel. For the sake of simplicity, in the present invention, the inside of the roof and / or side panels of the heat insulation cage is collectively referred to as "inner layer", and the outside is collectively referred to as "outer layer". It is also referred to as the "inner layer" in this case. It should be noted that the present invention can be applied regardless of whether the heat-insulation layer of the top plate is located inside or outside the base body, and whether the side plate is a single-layer or multi-lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com