Production technology for warp printed fabric by thermal transfer

A textile fabric and production process technology, applied in the production process field of thermal transfer warp printing products, can solve the problems of warp thread damage, high cost, waste of manpower, material resources and time, etc., achieve simple and reasonable production process, and reduce production costs , The effect of reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

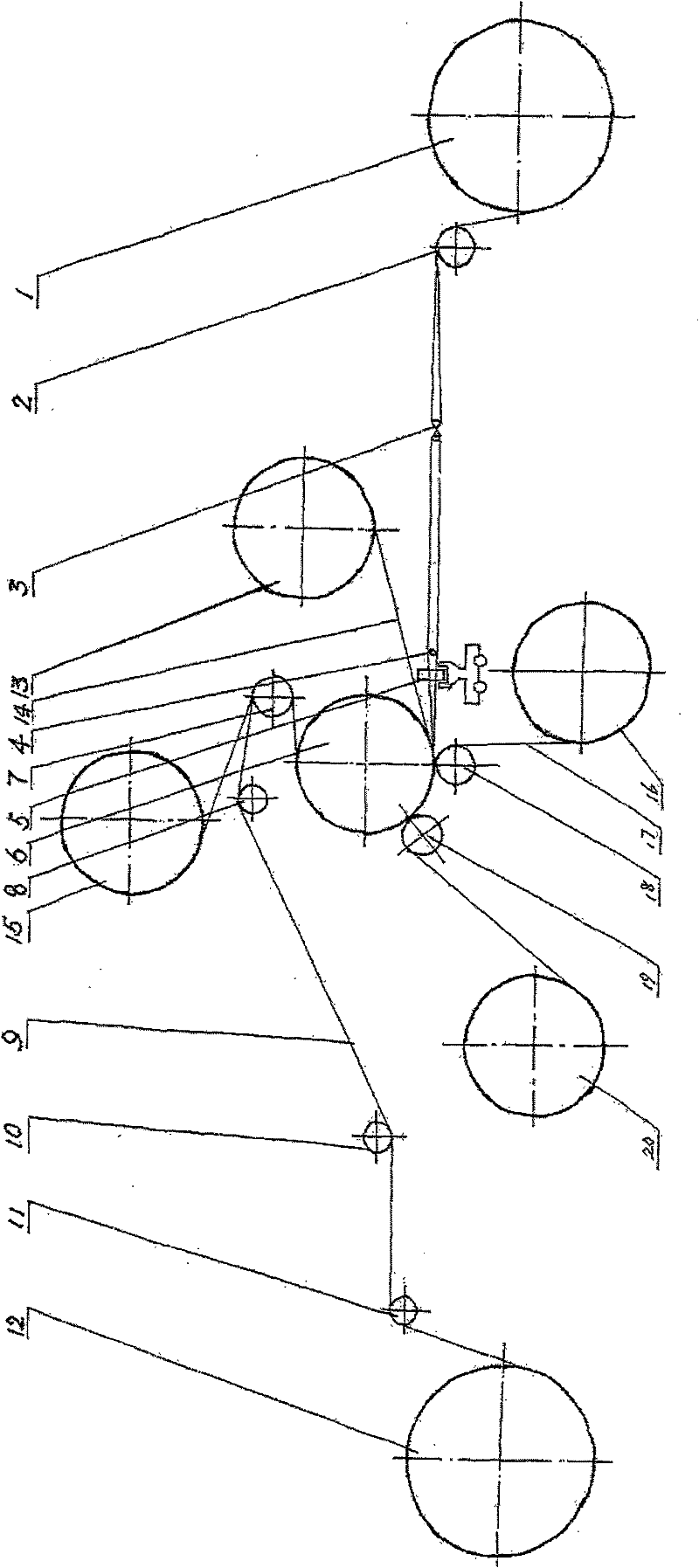

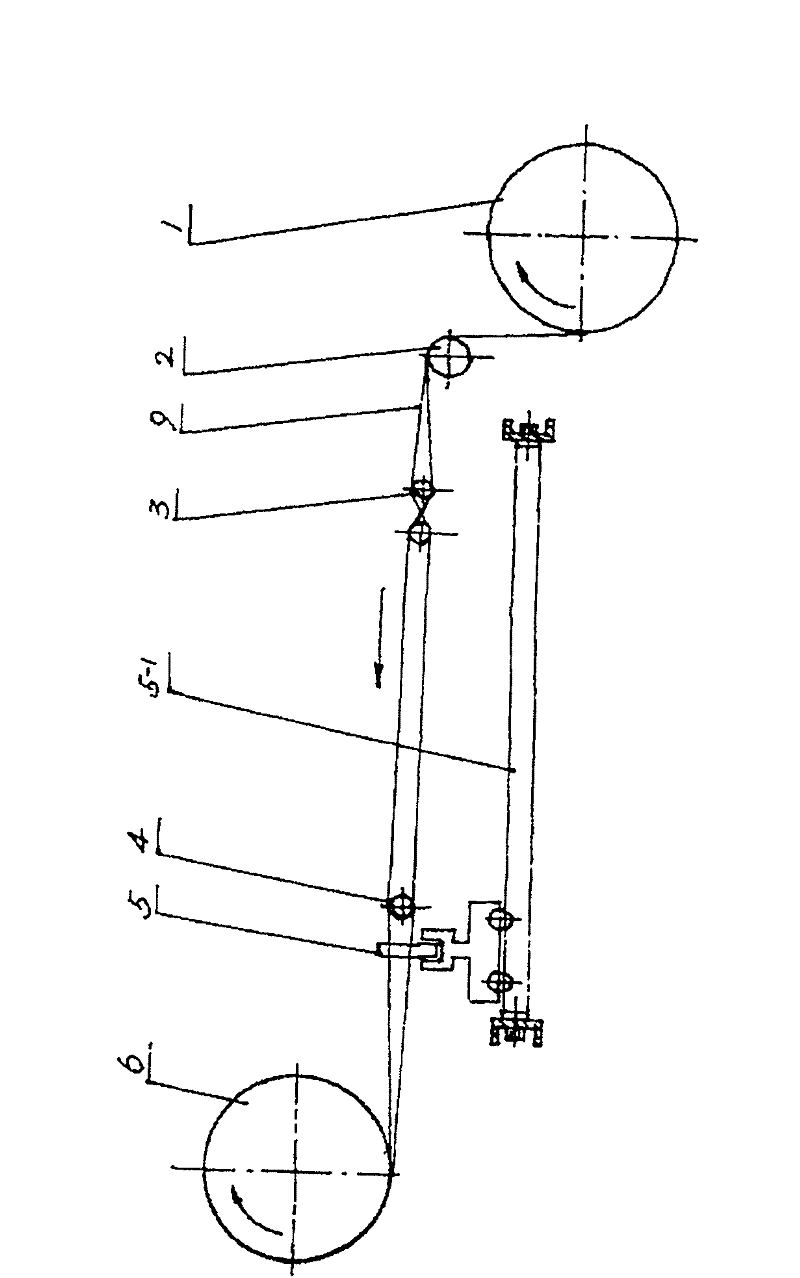

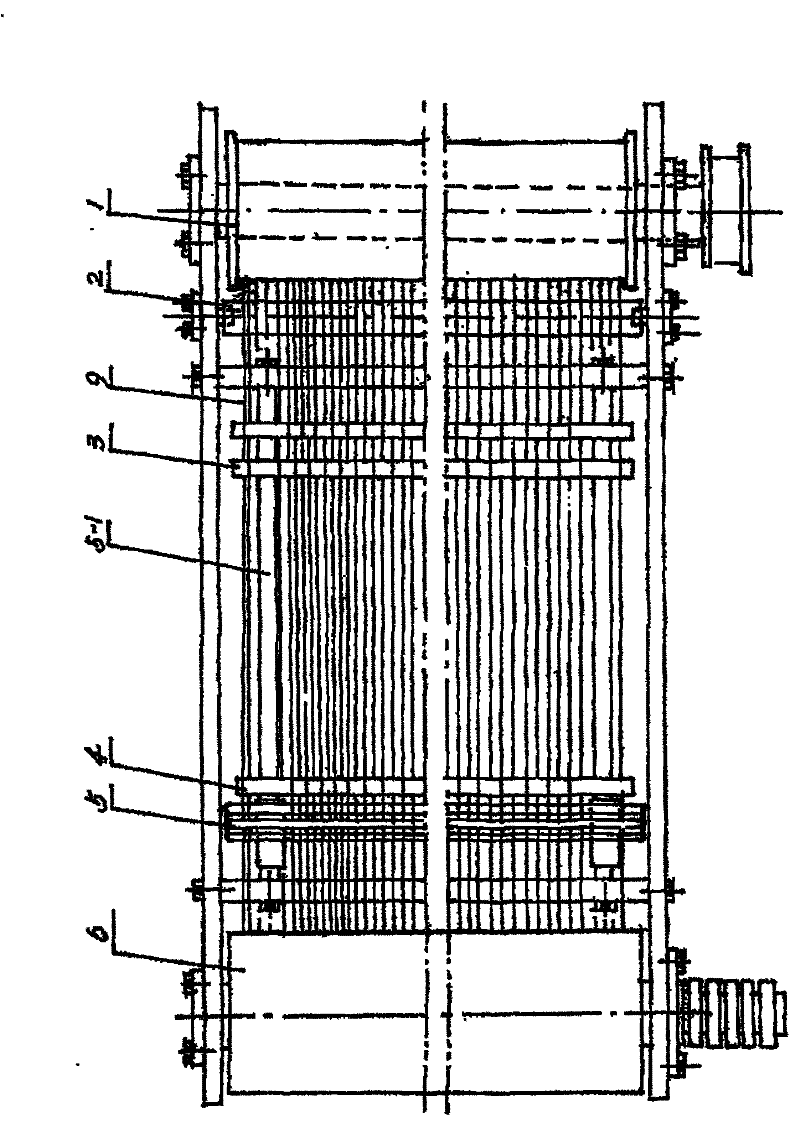

Method used

Image

Examples

example

[0066] To produce a kind of all-polyester sutra-printed women's clothing fabric, according to the production process of the sutra-printed textile fabric, follow the steps in turn:

[0067] 1. Raw material selection:

[0068] 1. The raw material of the warp is 50D / 72F polyester low elastic yarn with 10 twists / cm, twisted in S direction.

[0069] 2. The weft thread is made of 50D / 72F polyester low elastic yarn with 18 twists / cm, twisted in 2Z2S.

[0070] 2. Winding: The winding process is the same as the conventional process, and the quality of the winding is strictly controlled.

[0071] 3. Twisting: The twisting process is the same as the conventional process, and the quality of twisting is strictly controlled.

[0072] 4. Warping: The warping process is the same as the conventional process, but broken ends, mis-twisted, rolled-twisted, and cross-warped are not allowed.

[0073] 5. Heat transfer printing: heat transfer temperature 190°C, transfer time 25 seconds, warp print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com