Construction method for special-shaped steel cofferdam

A construction method, steel cofferdam technology, applied in the direction of infrastructure engineering, construction, etc., can solve problems such as failure to achieve construction goals, difficulties in construction of pile foundations and caps, and large slopes of river beds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with accompanying drawing.

[0053] 1. For the special-shaped steel cofferdam of the 1# pier of Shaoguan Zhenjiang Bridge:

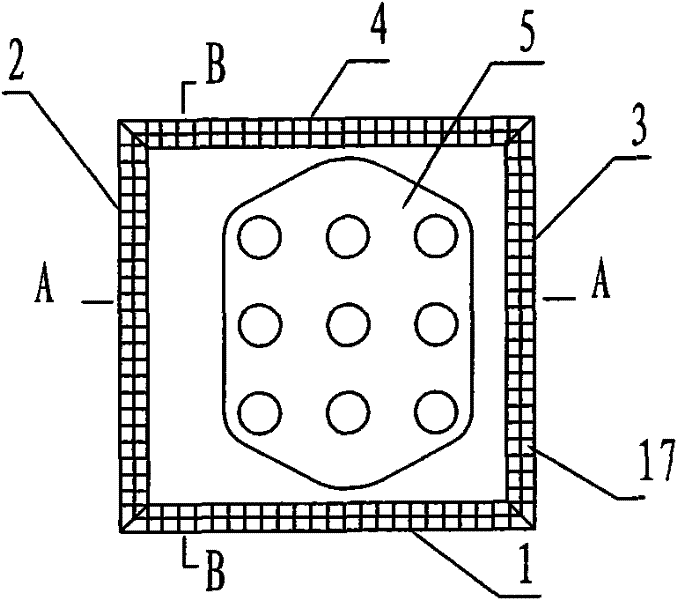

[0054] Such as figure 1 As shown, according to the layout of the pile foundation of the 1# main pier of Shaoguan Zhenjiang Bridge and the shape of cap 5, the steel cofferdam is designed as a rectangular open double-wall structure, that is, steel cofferdam 17, consisting of downstream side 1, Ganzhou side 2, Shaoguan side 3 and upstream side 4 are composed, the outer wall of the rectangle is 17m×17m, the inner wall of the rectangle is 15m×15m, the compartment width is 1m, and the inner frame is reinforced by ∠75×75×8mm angle steel connection; the so-called open is double The compartment formed by the wall is open, that is, the compartment is connected up and down, and concrete can be poured inward.

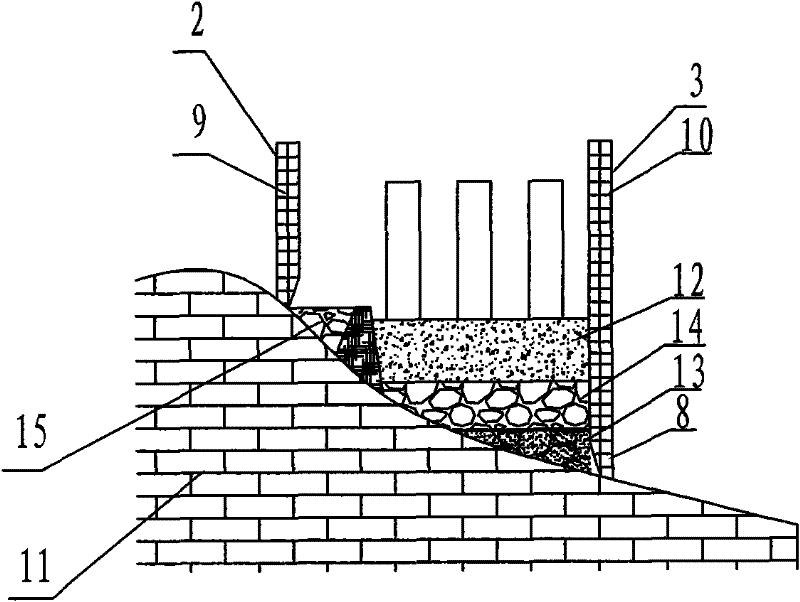

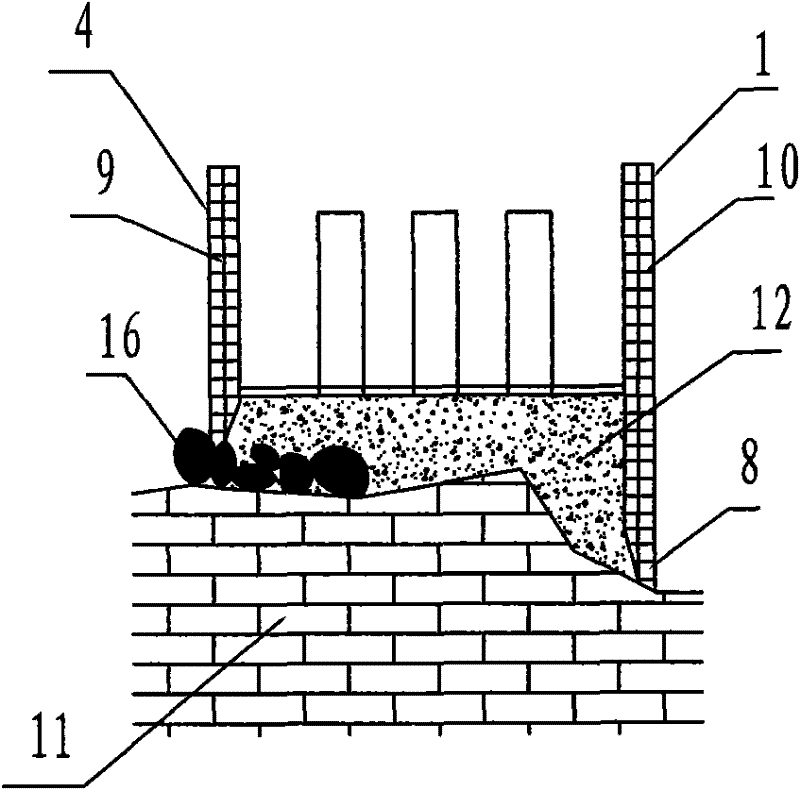

[0055] Such as figure 2 , 3 As shown, the wall thickness from the top of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap