Two-way thermal expansion valve

A thermal expansion valve, reverse technology, applied in valve details, valve devices, lighting and heating equipment, etc., can solve problems such as different requirements for throttling changes and complex operating environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

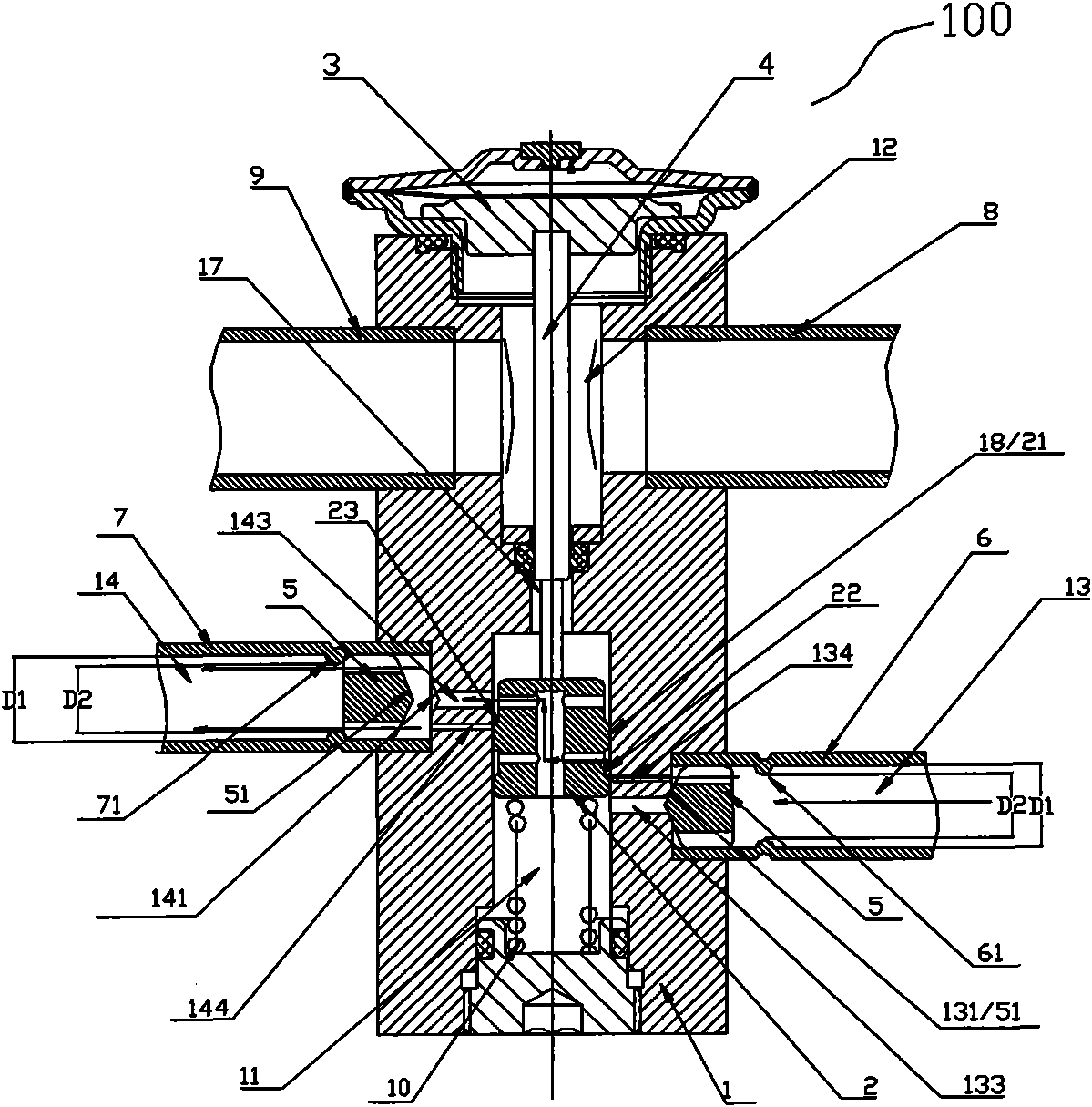

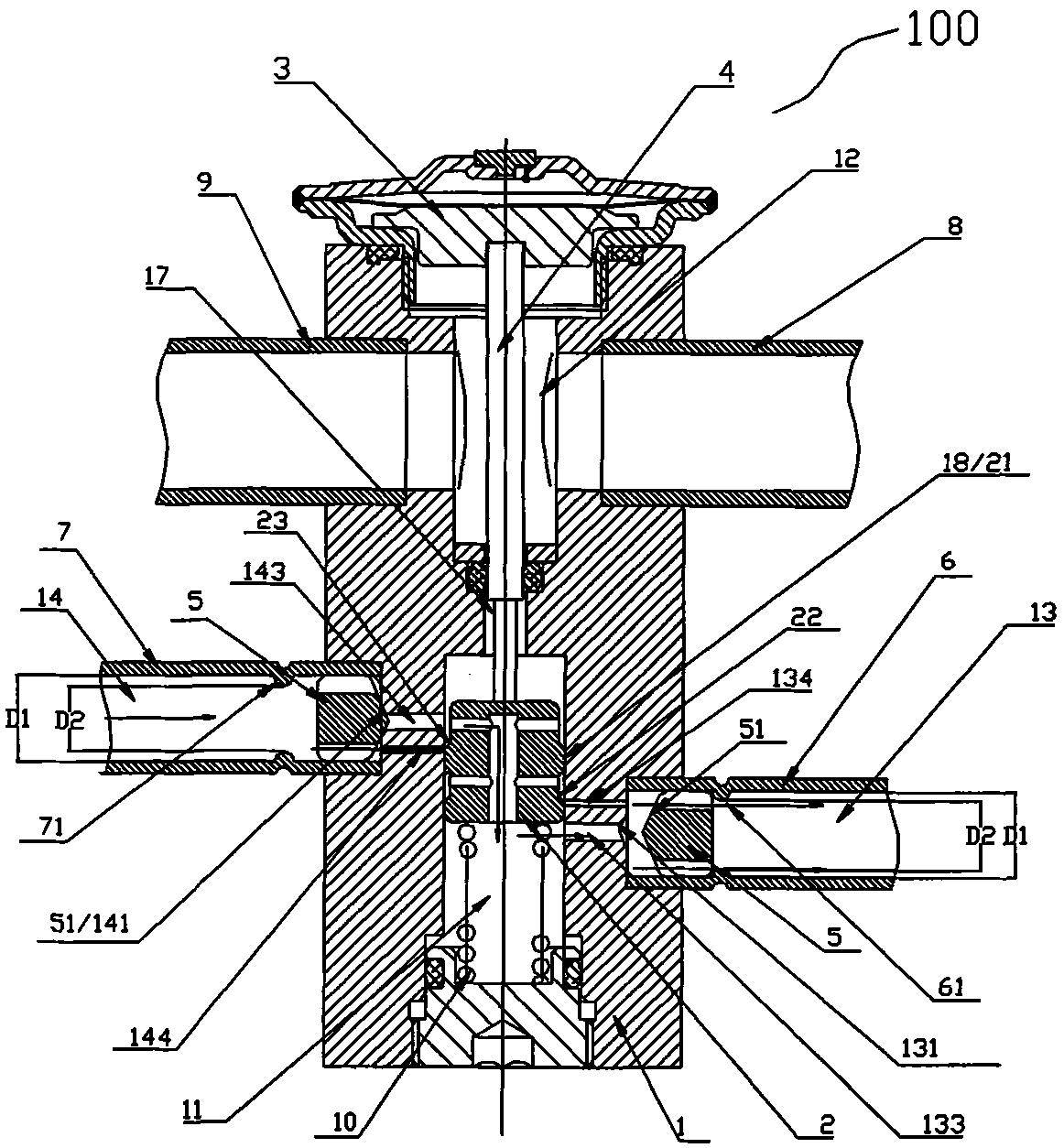

[0048] The two-way thermal expansion valve of the present invention is suitable for use in refrigeration systems. Since the principles of refrigeration systems are basically the same, a heat pump air-conditioning system is used as an example for illustration below.

[0049] Figure 7 It is a typical refrigeration flow diagram of a refrigeration system in which a bidirectional thermal expansion valve is applied to a heat pump air conditioner. In the refrigeration system, the refrigerant flow path mainly includes: a compressor 101, an electromagnetic reversing valve 102, a bidirectional thermal expansion valve 100, a first heat exchanger 103 (such as an outdoor heat exchanger), and a second heat exchanger 104 ( such as indoor heat exchangers).

[0050] When the air conditioner is in cooling operation, the electromagnetic reversing valve switches 102, and the refrigerant circulation path is: high-pressure gas discharged from the compressor 101 → reversing valve 102 → first heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com