Fluorescent penetrant detecting method

A fluorescent penetrant and detection method technology, applied in the field of fluorescent penetrant detection, can solve the problems of polluting the surrounding environment, affecting the accuracy of detection, and no obvious improvement in labor intensity, so as to achieve the effect of improving the environment and strengthening the relative sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention will be described below, by way of example only, with reference to the accompanying drawings. For ease of explanation, the description of the preferred embodiment will be by means of a fluorescent penetrant detection system.

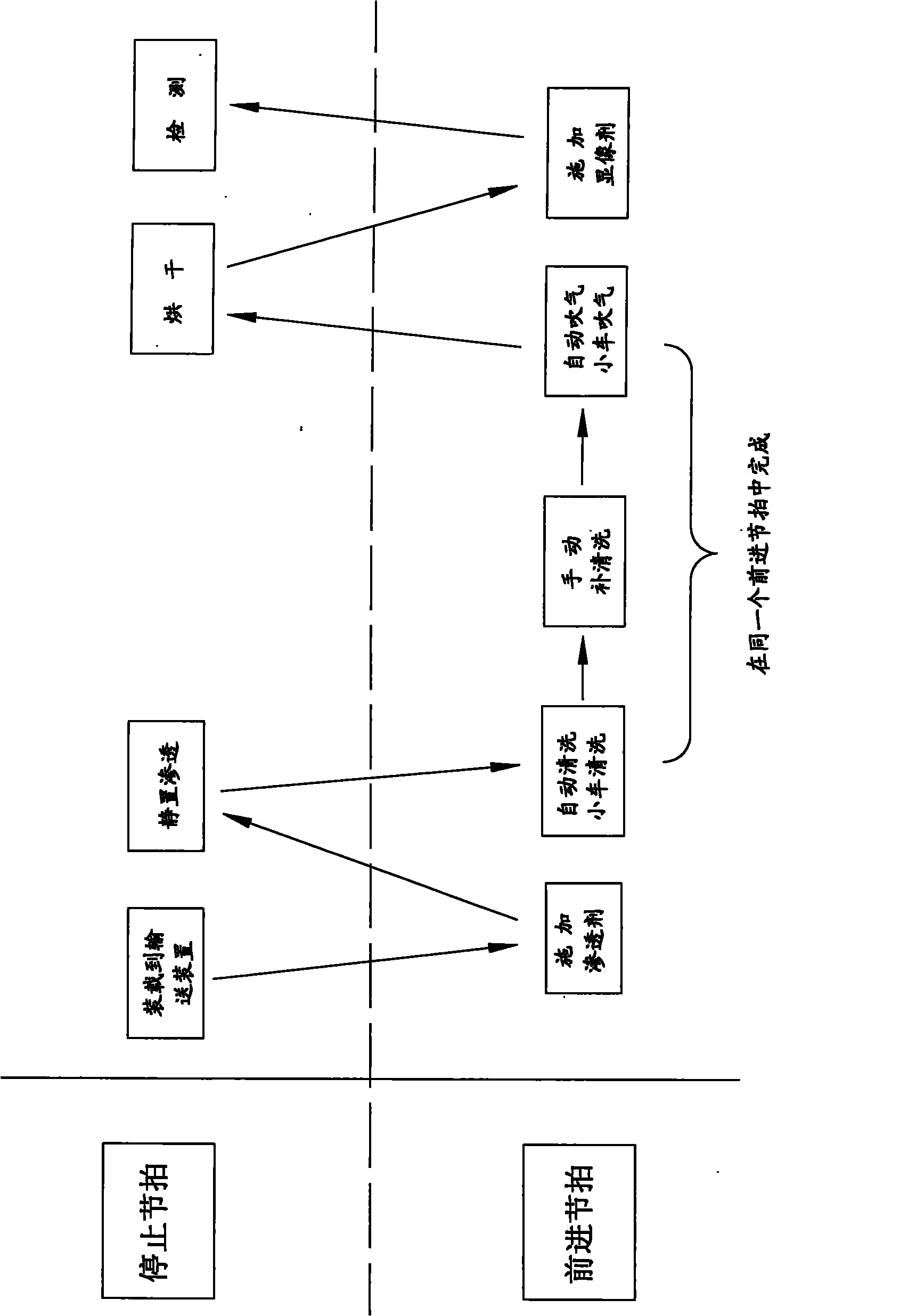

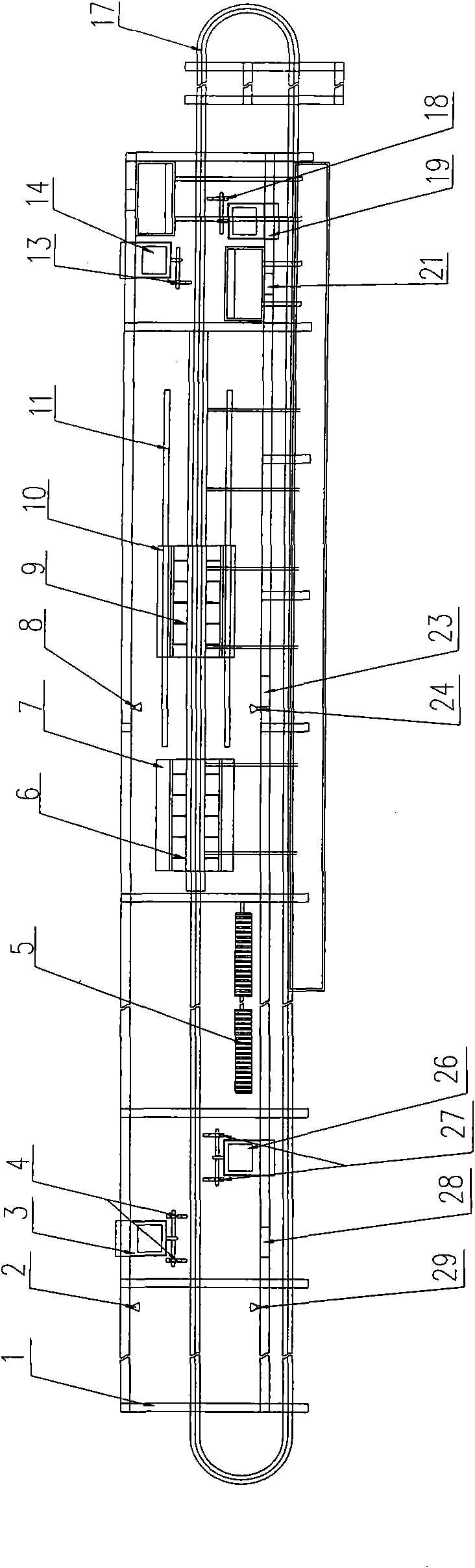

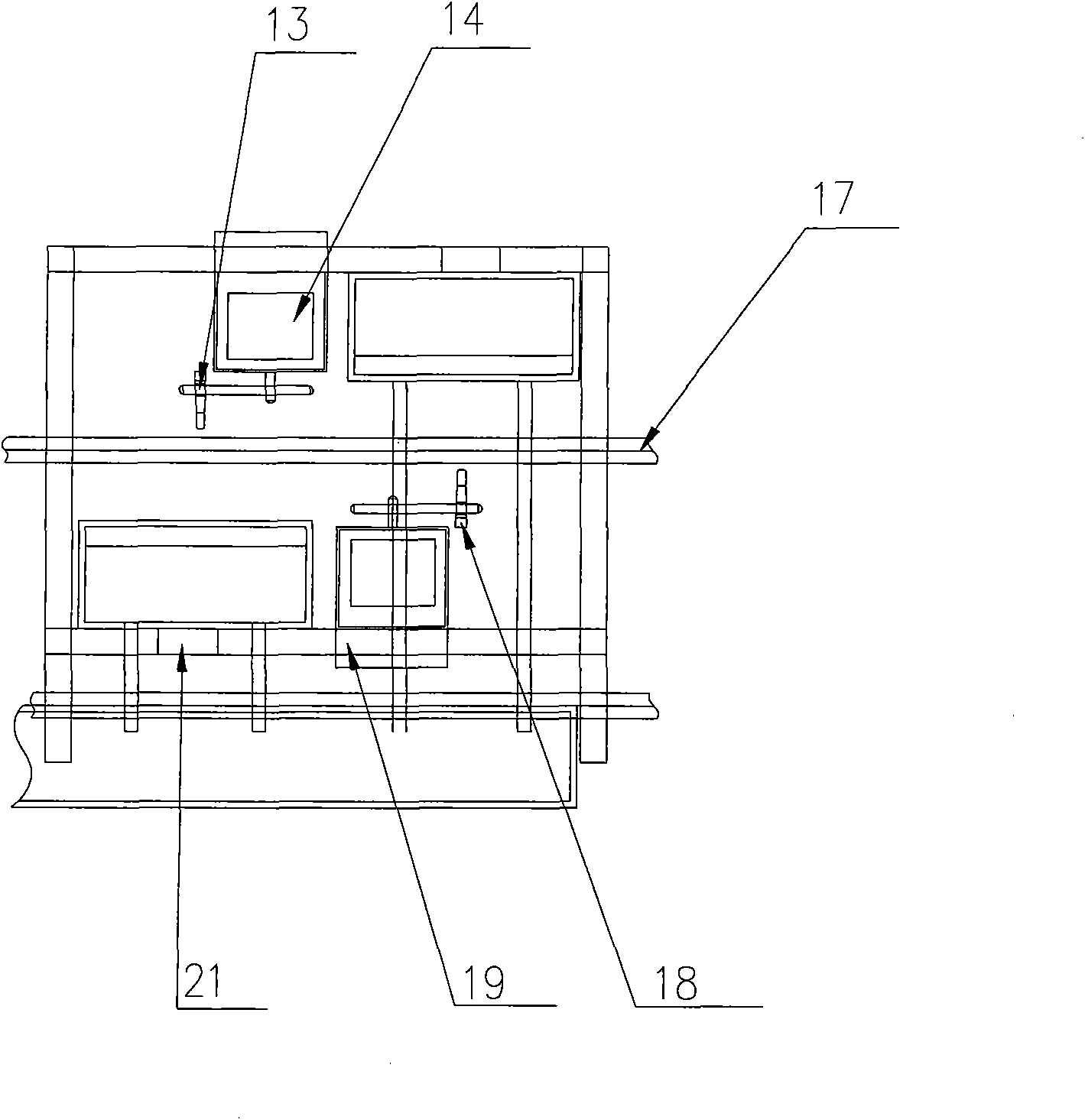

[0034] figure 2It is the overall structural layout diagram of the fluorescent penetrant detection system used to implement the preferred embodiment of the present invention, including: a conveying part, a penetrating agent part, a cleaning part, a drying part, an imaging agent part, a detection part and a control part (Fig. not shown in ).

[0035] Wherein, the penetrating agent application part, the cleaning part, the drying part, the developing agent application part and the detection part are sequentially arranged from right to left, and have independent compartments 1 respectively, wherein the compartments 1 of each part are connected by a large The enclosed compartments are separated by partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com