Scrapping plate for a cotton picker

A scraper, cotton technology, applied in the direction of picking machine, application, harvester, etc., can solve the problems of excessive distance, reducing the optimal picking performance of the spindle bar, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] specific implementation plan

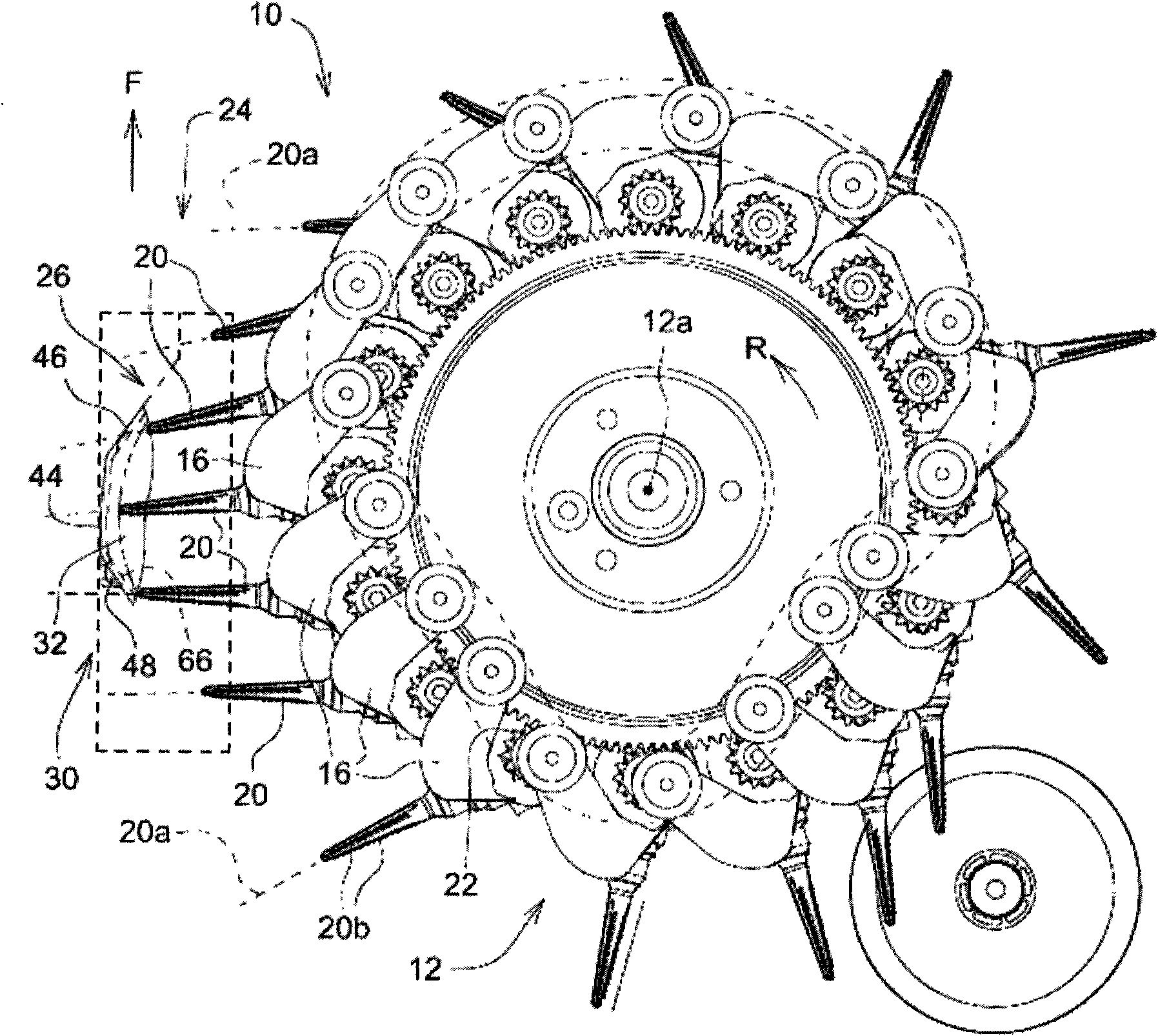

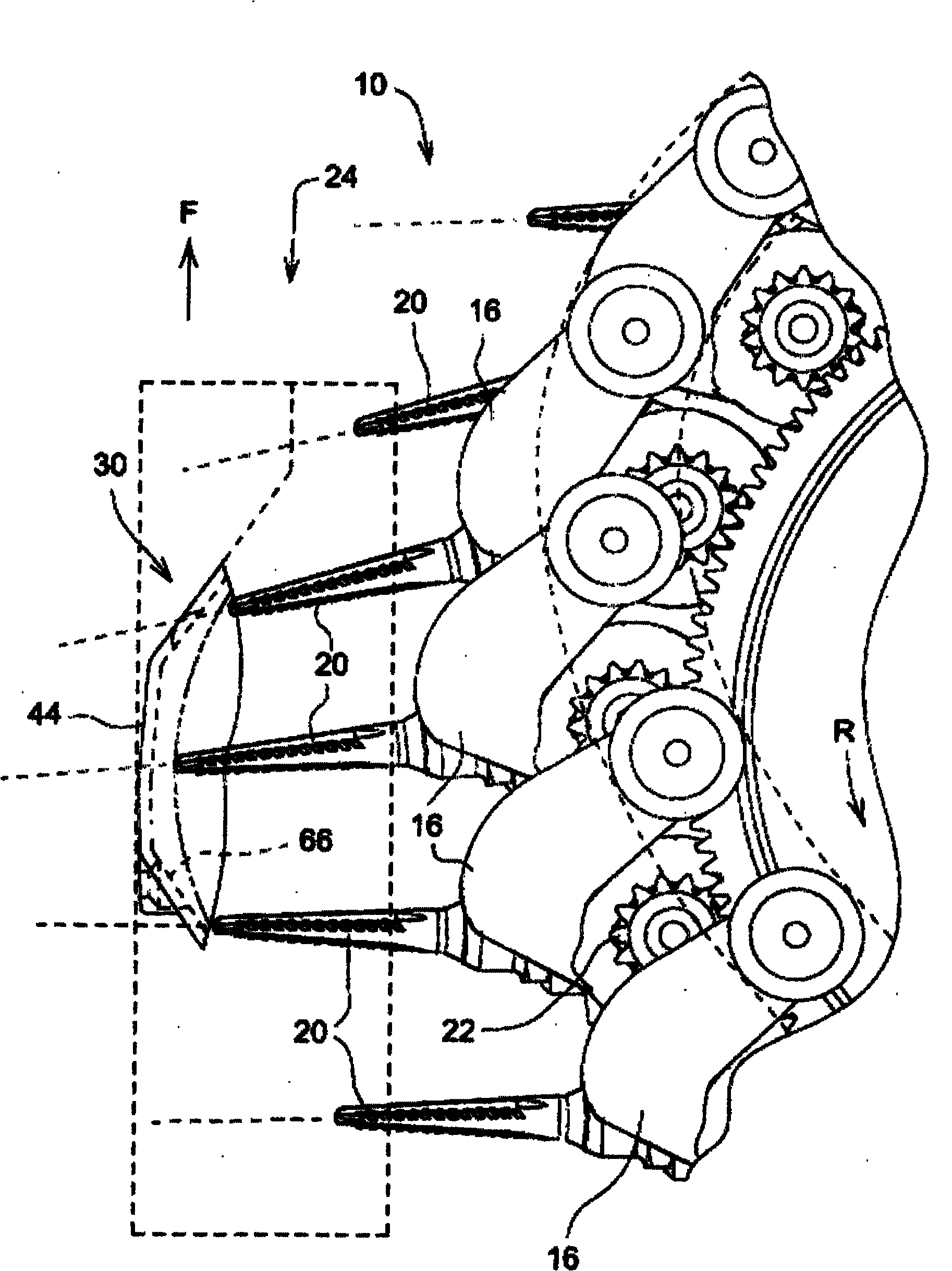

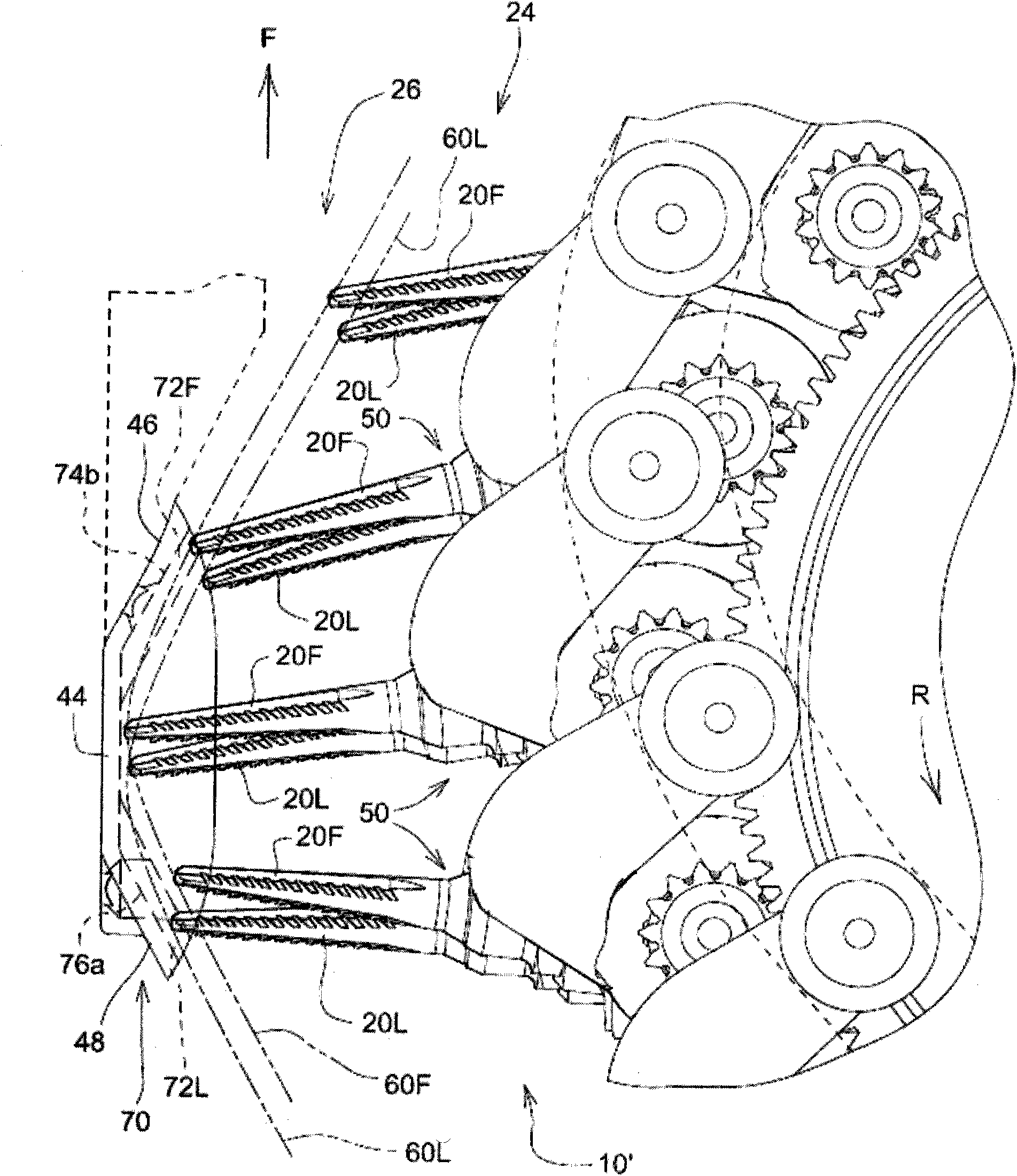

[0017] refer to figure 1 (Prior Art), where a portion of a cotton picker row unit 10 is shown having a rotating picking drum 12 with upright picking bars 16 . A plurality of vertically aligned cotton picker spindles 20 are mounted for rotation about a spindle axis 20a by a conventional spindle drive 22 . As row unit 10 moves in forward direction F, a row of cotton plants enters crop receiving area 24 and is engaged by spindles 20 rotating within picking area 26 . Drum 12 rotates about drum axis 12a in direction R at a speed synchronous with the row unit forward speed so that the rearward speed of spindles 20 is approximately equal to the row unit forward speed and the spindle speed in picking area 26 tends relative to the cotton plant. close to zero. The rotating spindle 20 includes a barbed zone 20b that engages and breaks the bolls and removes cotton from the plant.

[0018] Scrapers 30 are provided to increase picking efficiency and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com