Secondary driving device for heavy numerical control roller grinder

A roll grinding machine and driving device technology, which is applied in the direction of grinding driving devices, grinding machines, grinding machine parts, etc., can solve the problems that the surface line speed of the roll is too small to meet the grinding requirements, occupies the workshop space, and is inconvenient to use. , to save money and workshop space, improve production efficiency and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

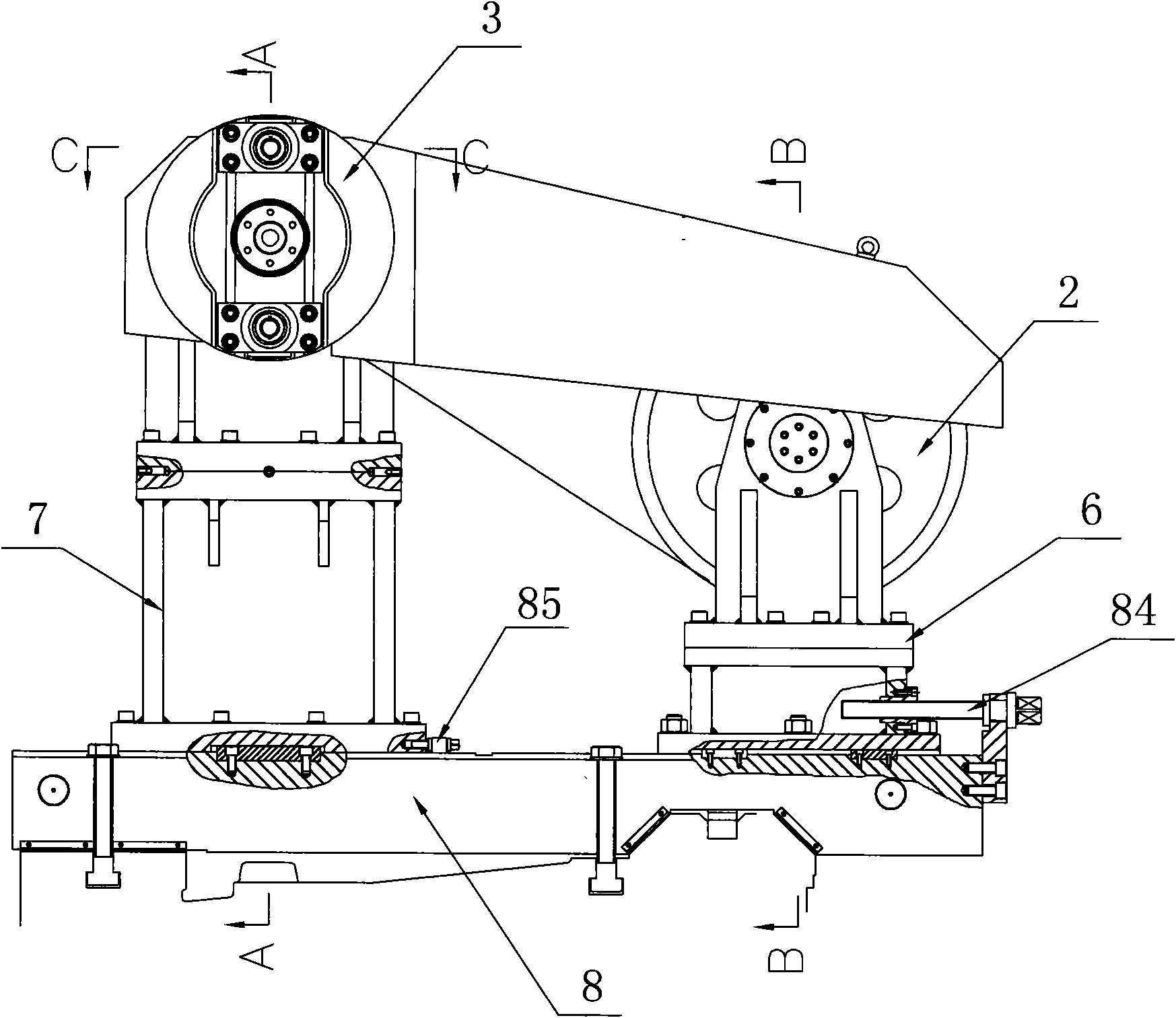

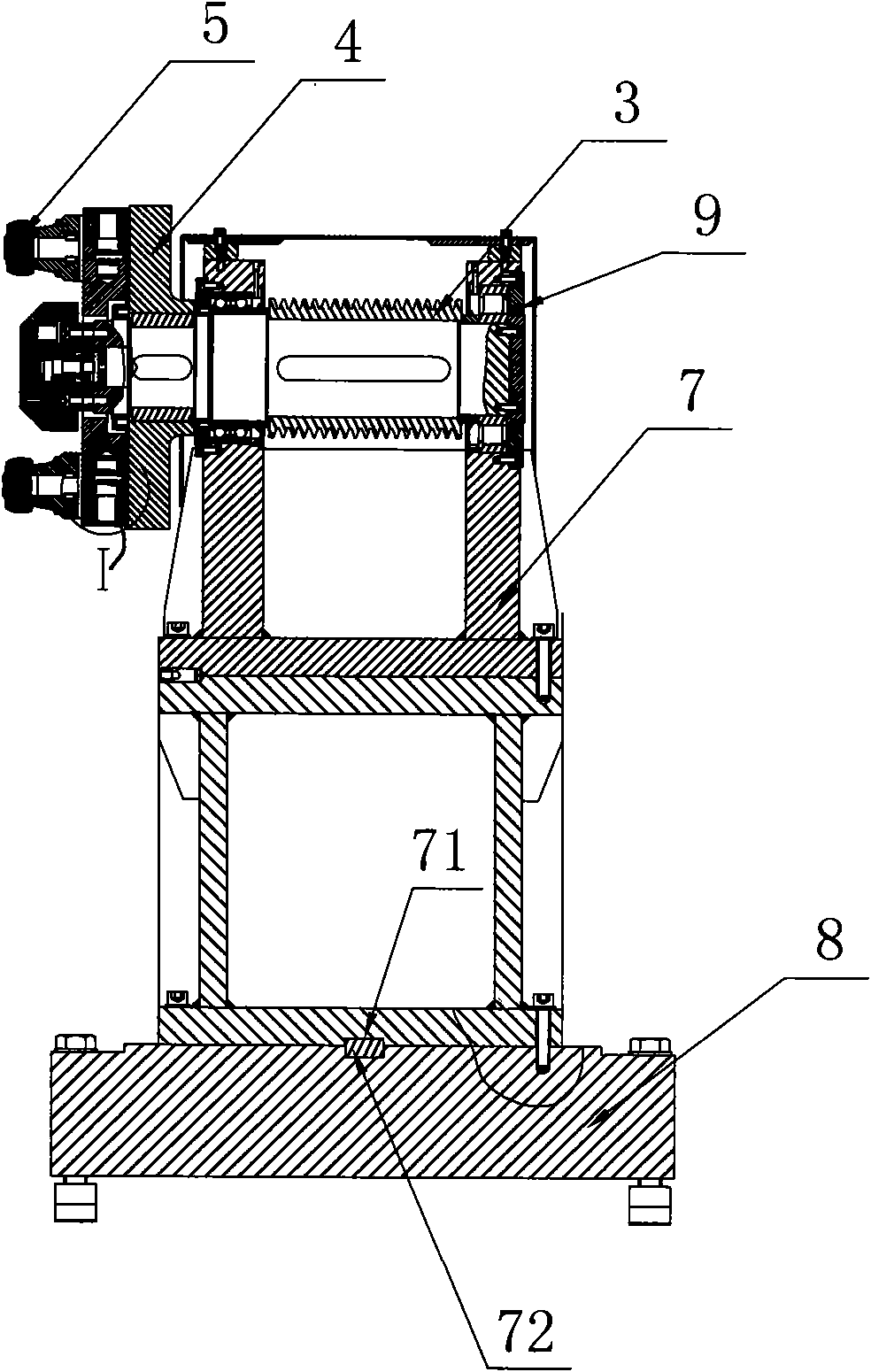

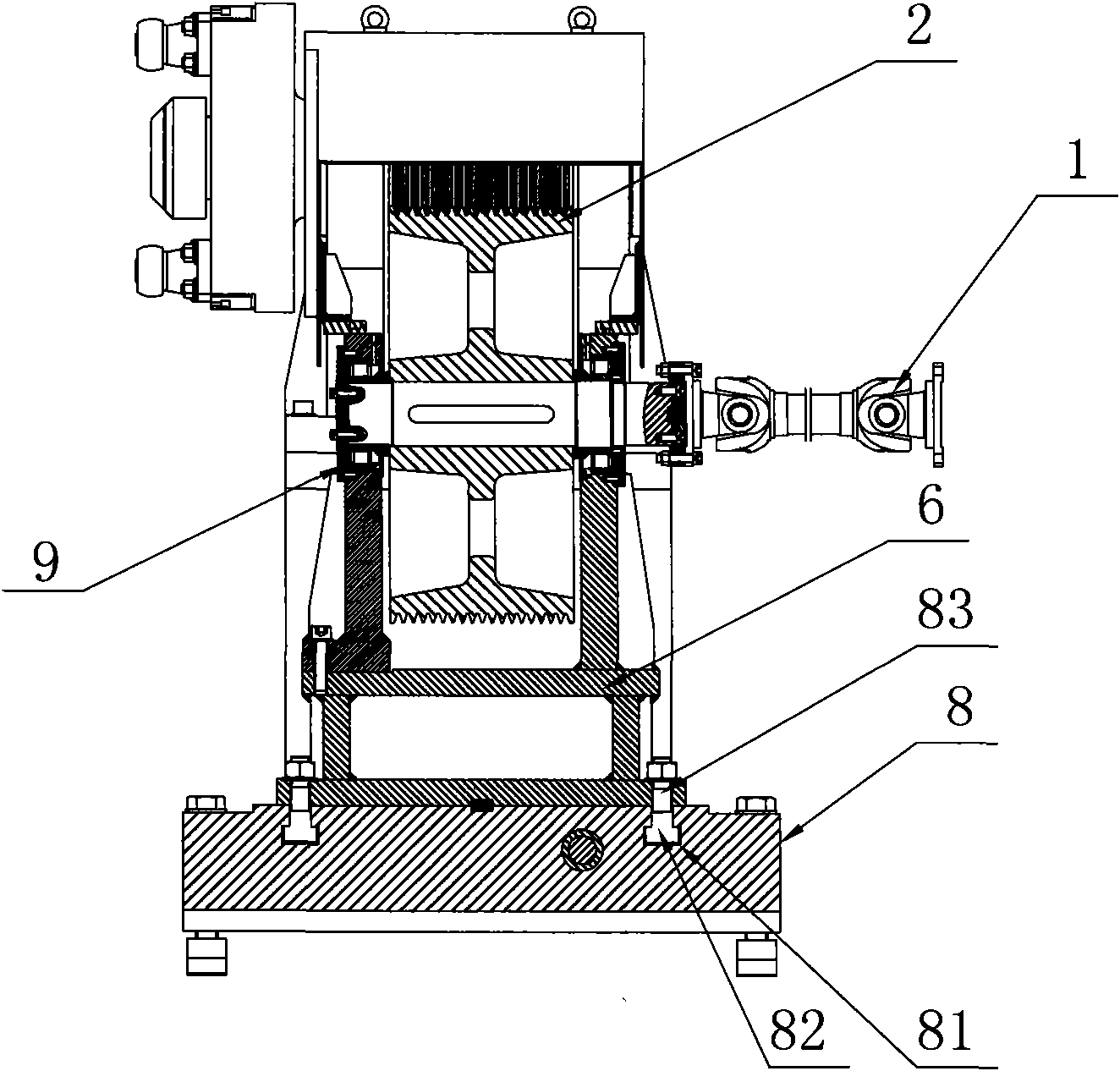

[0019] Embodiment: A second driving device of a heavy-duty numerical control roll grinder, the drive mechanism of the roll grinder outputs power to the first pulley, the first pulley drives the second pulley, the second pulley drives the third pulley, and the third pulley can drive the roll to rotate , wherein the diameter of the first pulley is smaller than the diameter of the second pulley, the diameter of the second pulley is smaller than the diameter of the third pulley, and a universal coupling 1, a fourth pulley 2, a fifth pulley 3, a connecting disc 4, a dial head 5, and a first pulley are provided. The first bracket 6, the second bracket 7 and the base 8 are based on the direction of use. One end of the universal coupling 1 is detachably and fixedly positioned on the rotating shaft of the second pulley, and the other end of the universal coupling 1 is fixed and positioned on the second pulley. On the rotating shaft of the four pulleys 2, the fourth pulley 2 drives the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com