Multifunctional bill printing machine

A multi-functional, printing press technology, applied in printing presses, rotary presses, printing and other directions, can solve the problems of large labor occupation, cumbersome operation, large workload, etc., achieve a reasonable and compact structure, simplify operation procedures, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

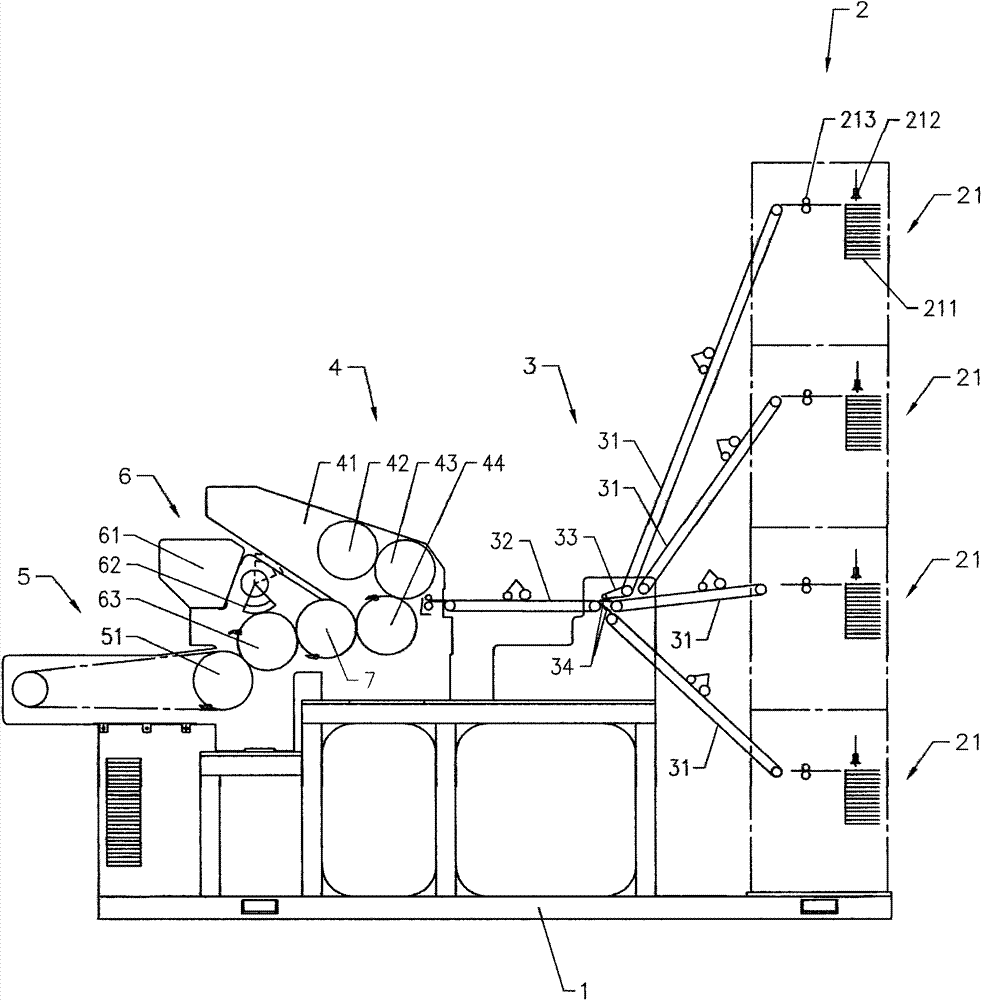

[0016] Such as figure 1 Shown, a bill multifunctional printing machine.

[0017] The bill multifunctional printing machine includes a frame 1, on which a paper feeding part 2 driven by a power device, a paper transfer part 3, a printing part 4 and a paper delivery part are sequentially arranged according to the direction of the paper sheet 5.

[0018] The paper feeding part includes several paper feeding units 21, and the several paper feeding units 21 are vertically arranged. The paper feeding unit 21 is an air-suction paper feeding unit, which includes a paper feeding platform 211 that can be lifted, a paper suction assembly 212 disposed above the paper feeding platform 211 , and a conveying roller set 213 for sending out paper sheets. The paper suction assembly 212 includes a paper suction tube and a paper suction nozzle, and the paper suction tube communicates with a vacuum pump and can swing under the drive of a power device. When the paper suction nozzle is close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com