Method for maintaining blast furnace taphole

A technology of iron mouth and blast furnace, which is applied in the direction of blast furnace, blast furnace details, blast furnace parts, etc., can solve the problems of poor treatment effect, affecting the normal production of blast furnace, single maintenance method, etc., achieve short maintenance time, reduce gas leakage, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is further described, not limiting to protection scope:

[0019] A maintenance method for a blast furnace taphole. It is maintained according to the following steps:

[0020] Step 1: Remove the iron gate protection plate, first clean the iron grooves on both sides of the iron gate to the center line of the iron gate, then clean the iron gate mud sleeve to the surface of the iron gate composite brick, and then clean the dust in the iron gate frame 1 with the Debris cleaned up;

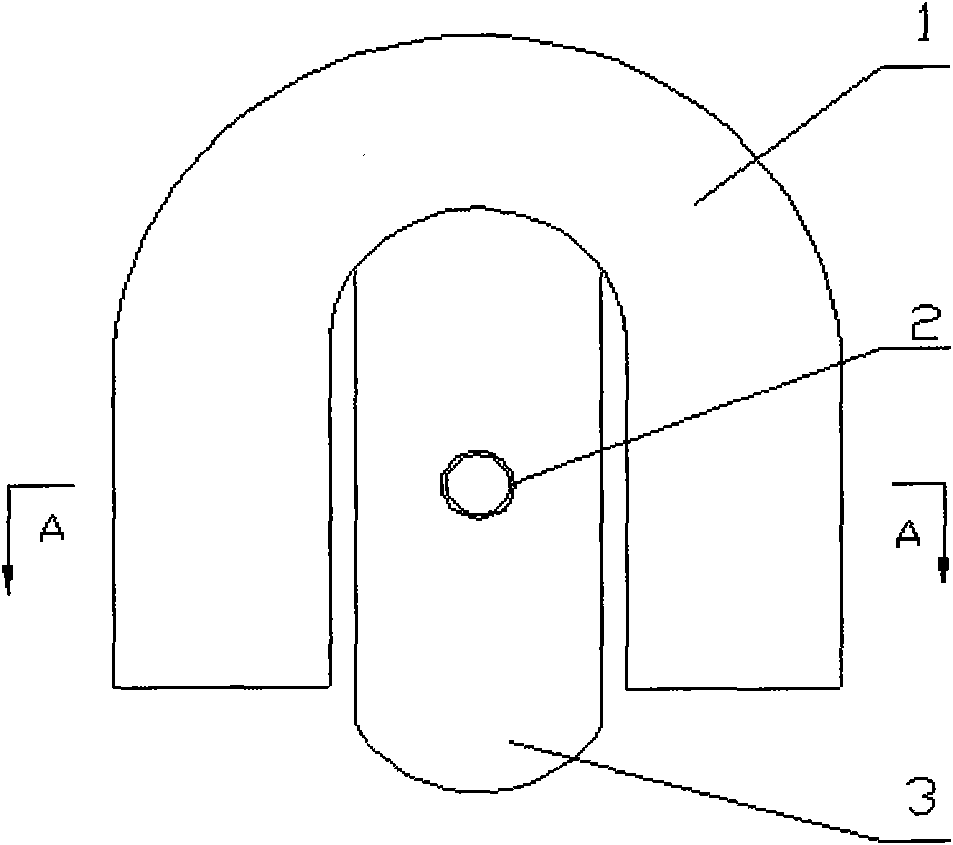

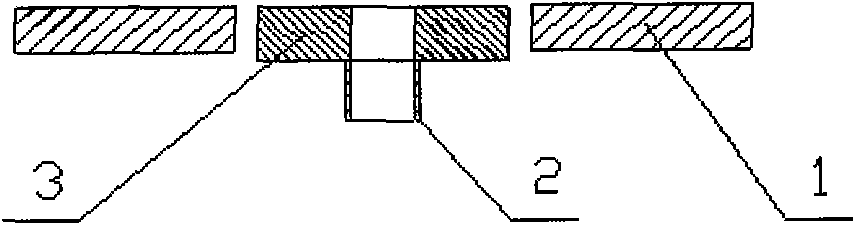

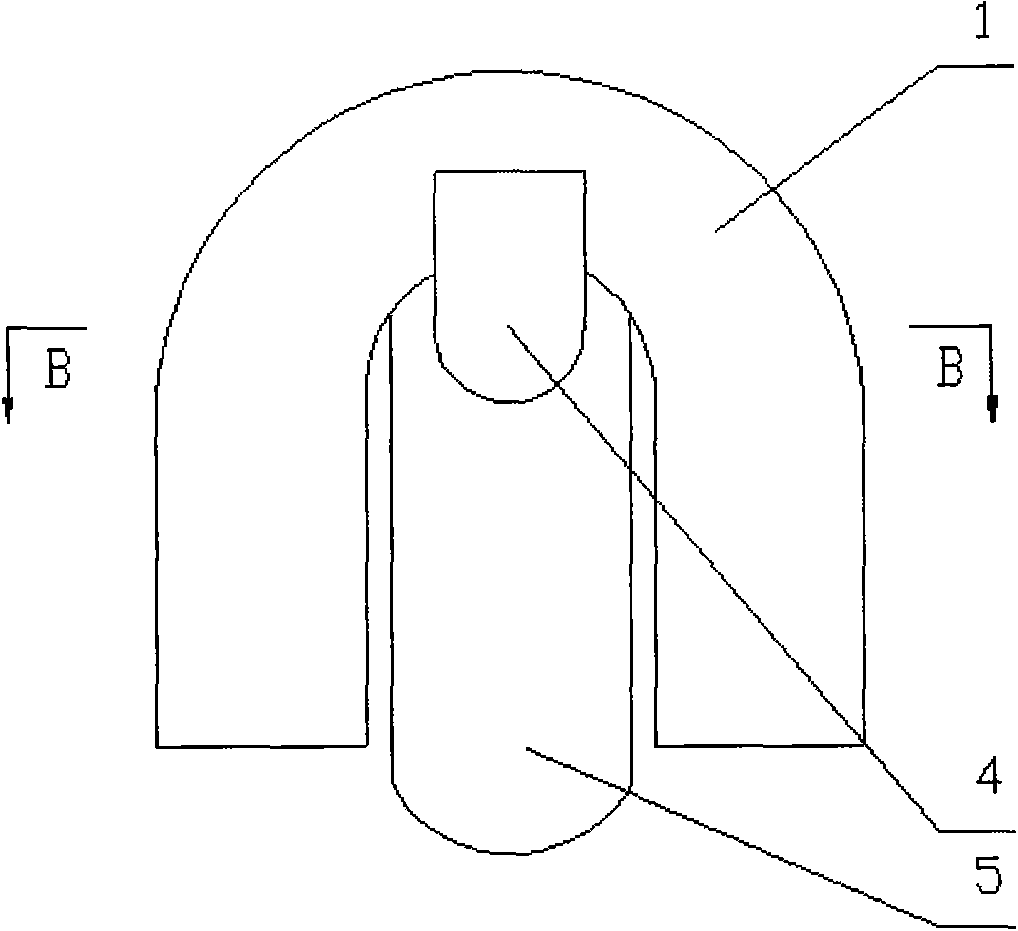

[0021] Step 2: Select a steel plate with a thickness of 30-40mm to make the blind plate 3, such as figure 1 with figure 2 As shown, first make grooves around the edges of the steel plate, then open a hole in the center of the steel plate, and weld a short grouting tube 2 with an outer diameter of 50 mm at the hole to obtain a blind plate 3; The blind plate 3 is welded to the iron mouth frame 1;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com