Observation system of water injection in fractured zone in coal seam goaf

An observation system and goaf technology, applied in testing machinery, earthwork drilling and mining, etc., can solve the problems of inaccurate measurement of leakage flow and low efficiency in each section of drilling, shorten observation time, improve work efficiency, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

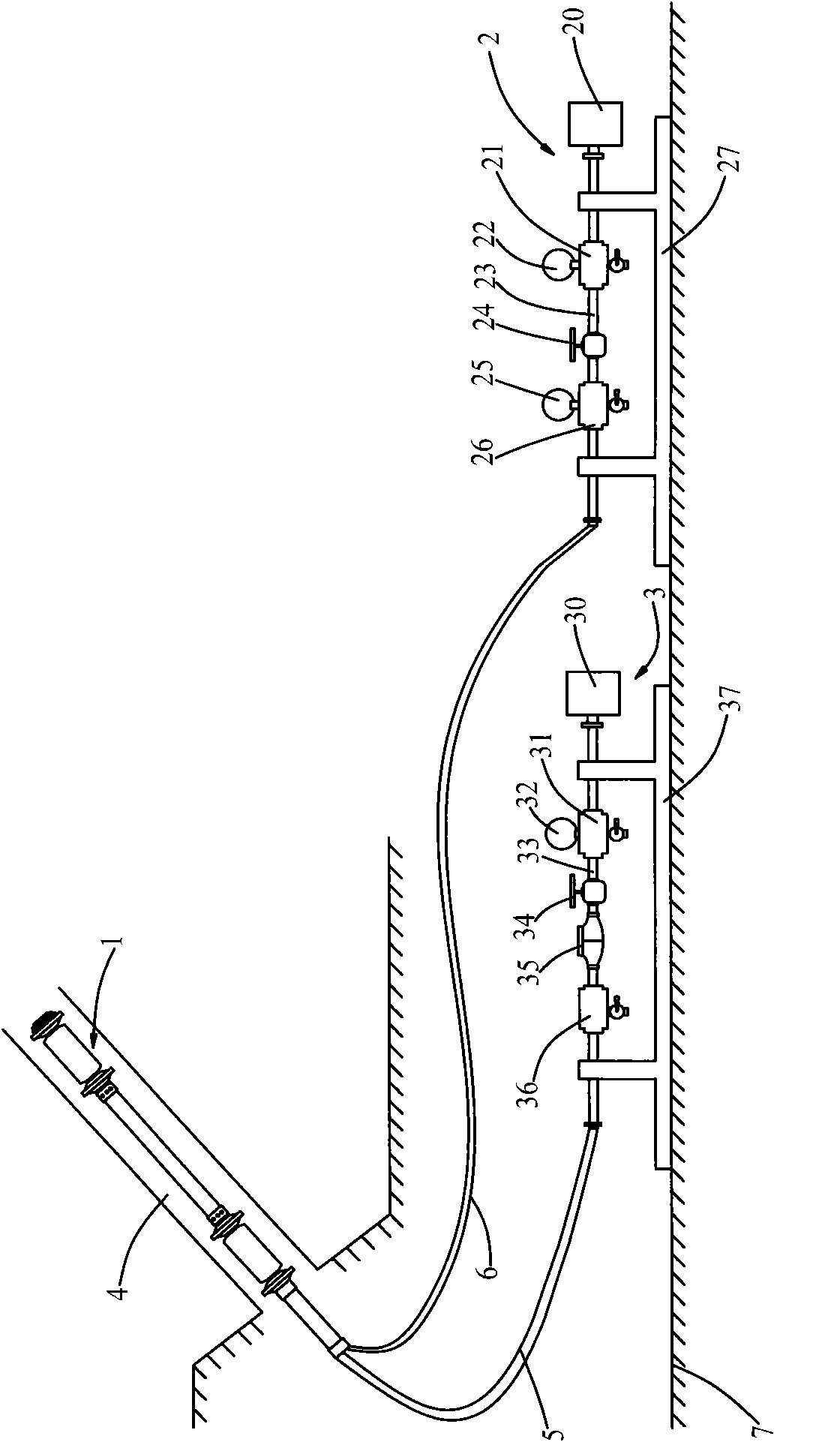

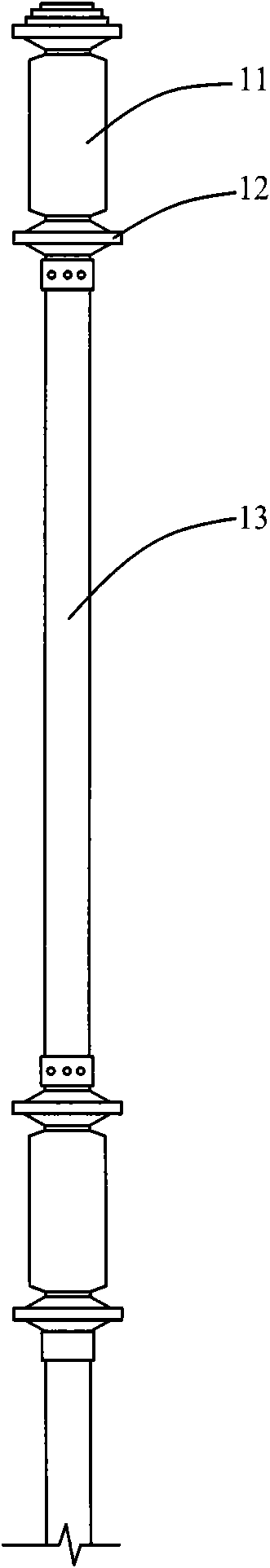

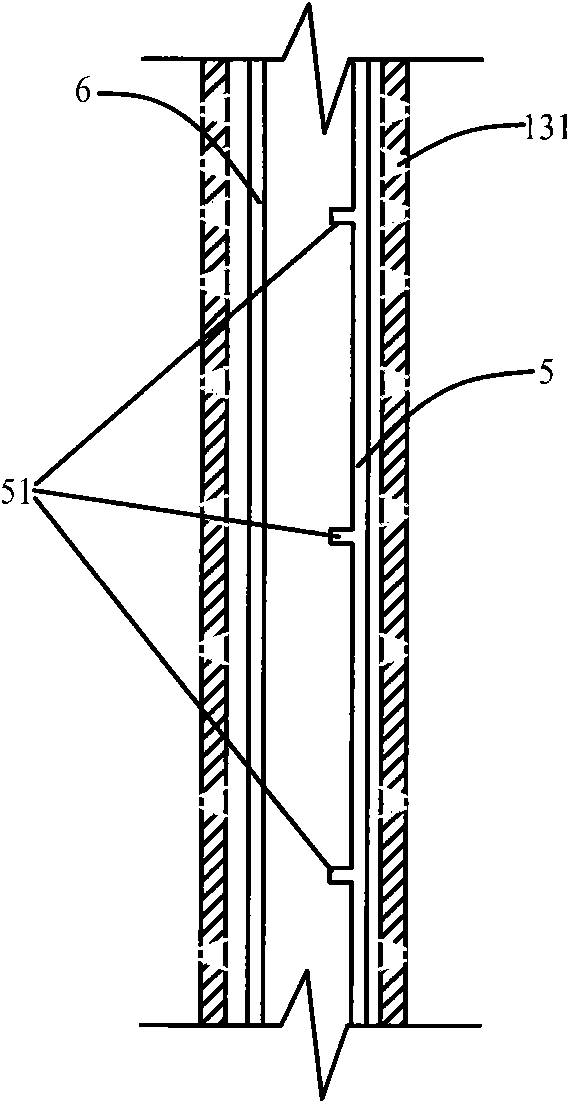

[0034] Such as figure 1 A kind of coal seam mined-out area fissure zone water injection observation system shown, comprises probe pipe 1, inflation control system 2 and water injection control system 3, and described probe pipe 1 (such as figure 2 shown), comprising two inflatable capsules 11, a water injection pipe 13 installed between the two inflatable capsules 11 through a connection block 12, an air pipeline 6 and a water pipeline 5, and the probe 1 is installed in the borehole 4, and the inflatable capsule 11 is in close contact with the wall of the borehole 4 after inflating, so as to achieve a good seal on both ends of the water injection pipe 13 between the inflatable capsules 11, so that the water flowing out from the water injection pipe 13 will not flow along the borehole 4 The direction of flowing out, said water injection pipe 13 is provided with a plurality of water injection holes 131 (such as image 3 shown), the water in the water injection hole 131 flows o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com