Burner consisting of partially premixed burner and completely premixed burner

A burner, pre-mixed technology, applied in the combination of multiple burners, burners, combustion methods, etc., can solve the problem of low heat storage, achieve weight reduction, optimize combustion performance, and simplify the structure of the burner Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

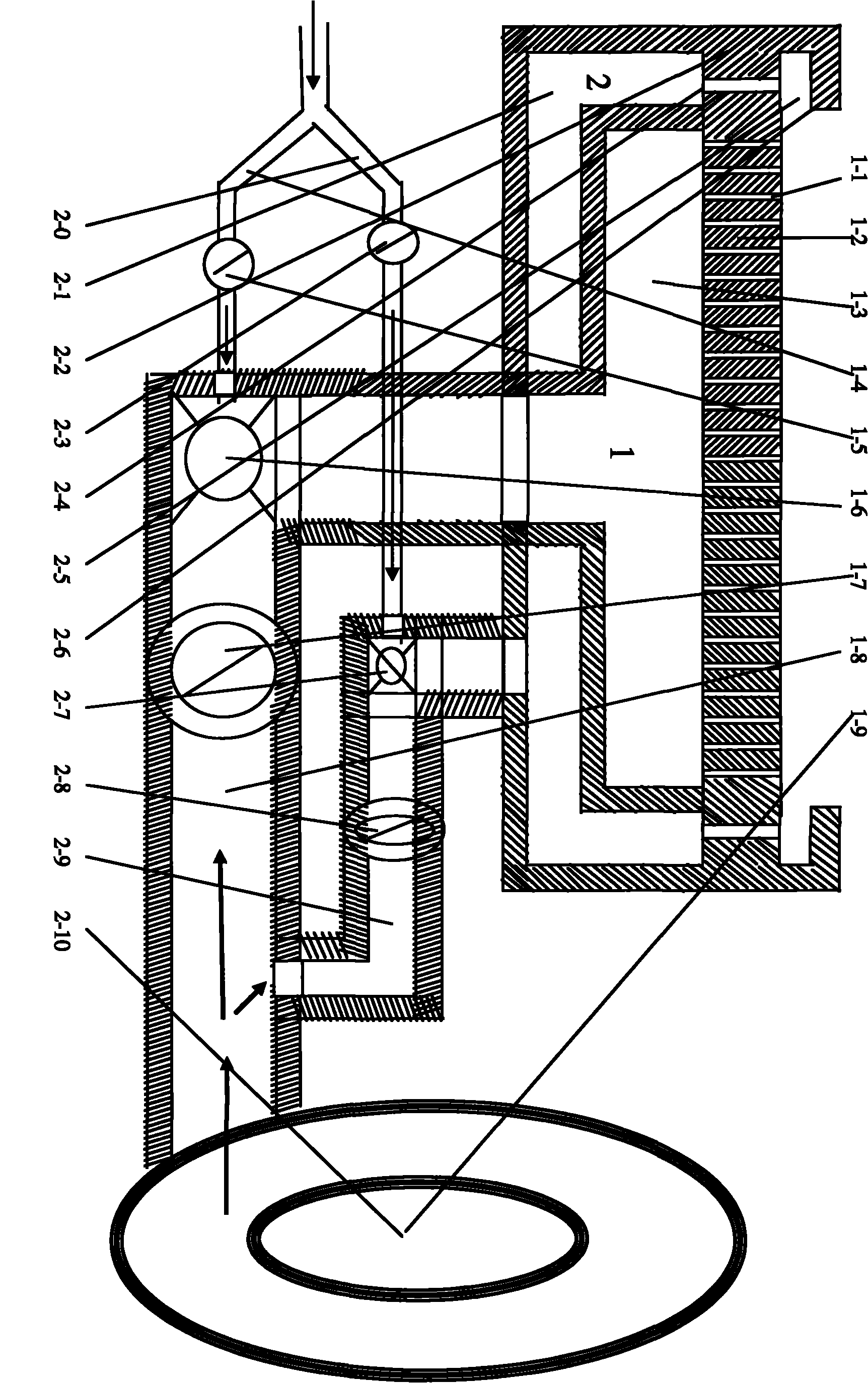

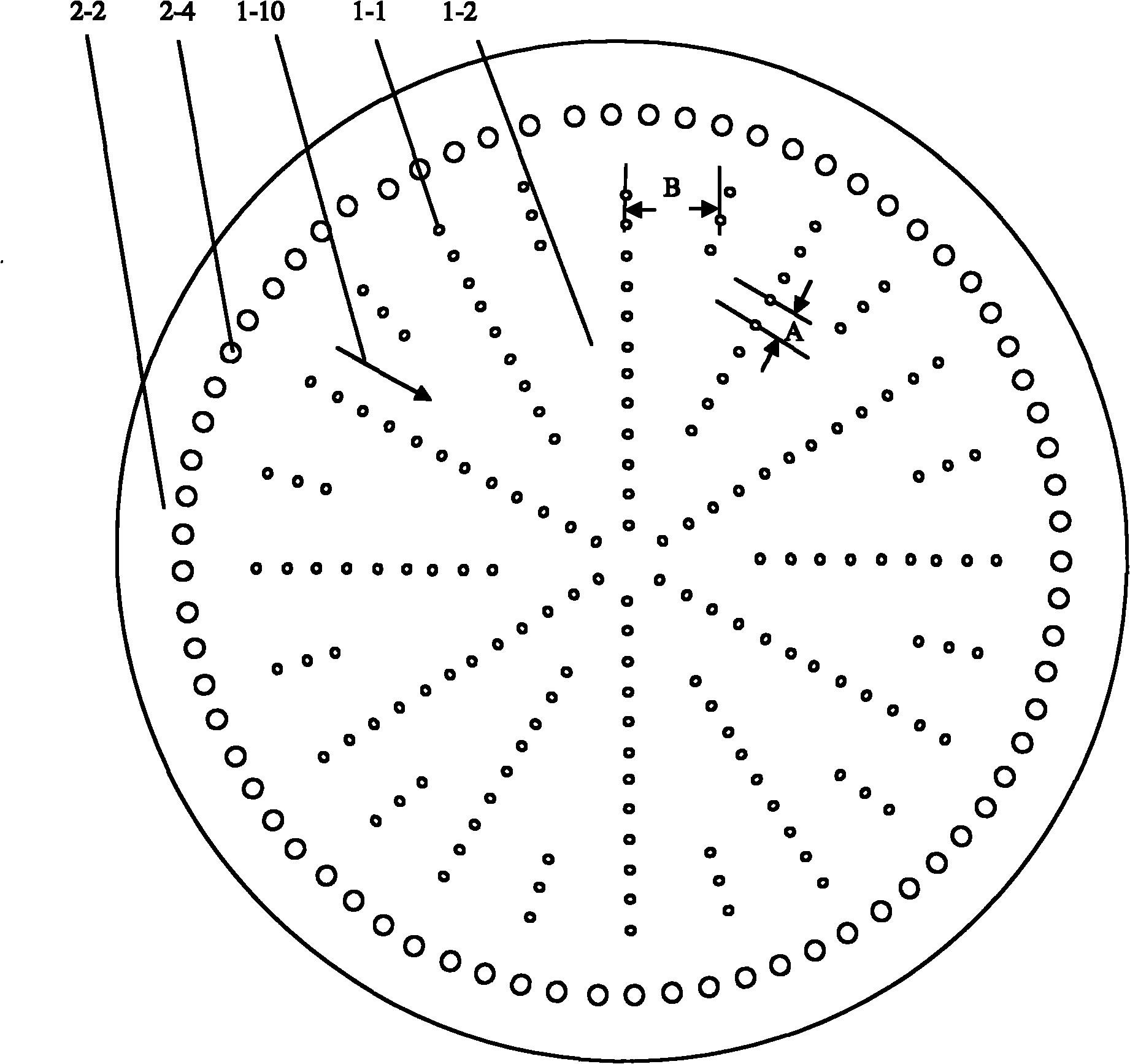

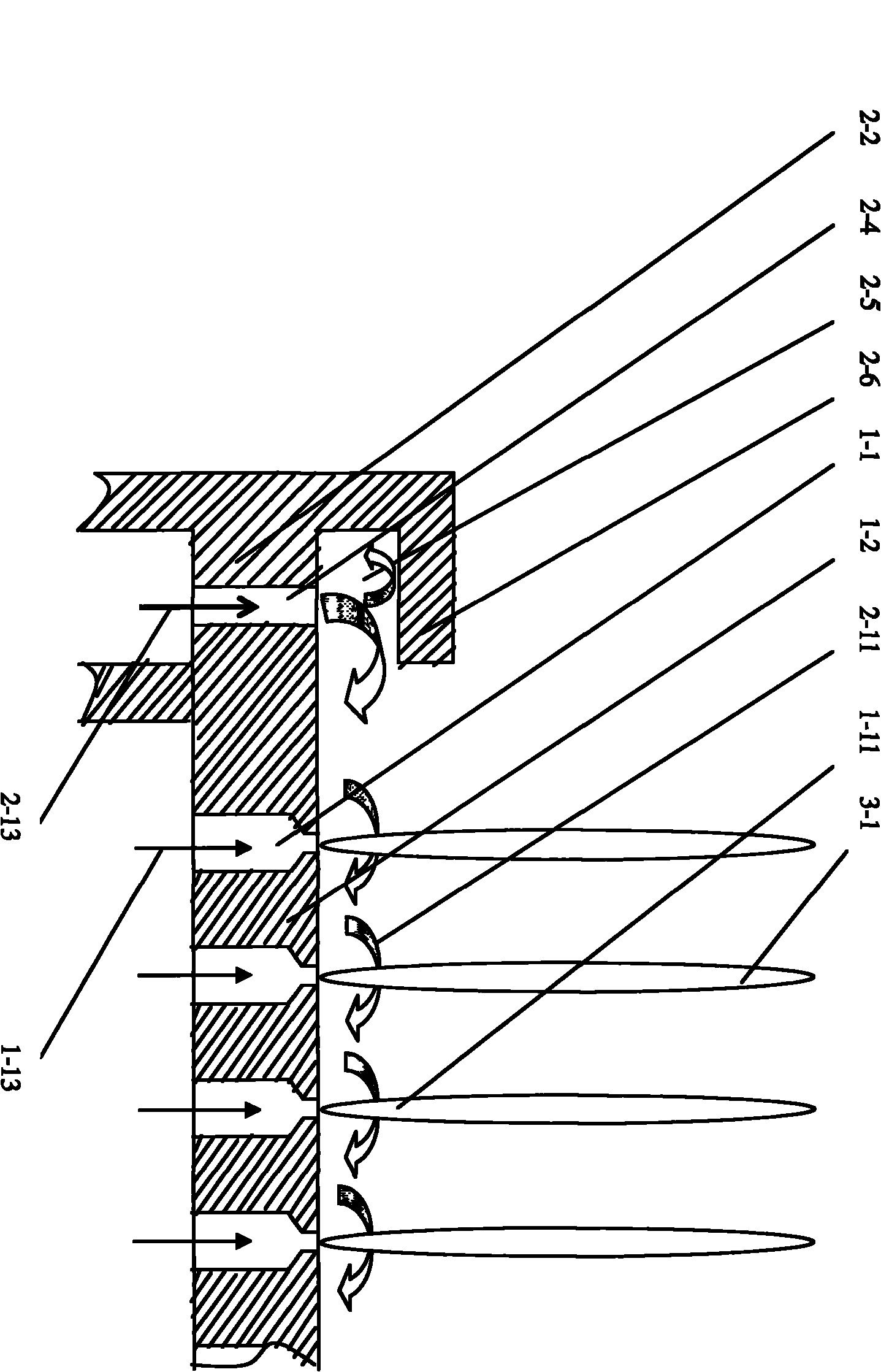

[0018] Embodiments of the present invention are: the air booster 2-10 is connected to the air pipeline 2-9, the air pipeline 2-9 is connected to the air regulating valve 2-8, the gas pipeline 2-0 is connected to the gas regulating valve 2-3, and the air regulating valve 2-8 is connected to the air and gas proportioning mixer 2-7 with the gas regulating valve 2-3, and the other end of the air and gas proportioning mixer 2-7 is connected to a part of the premixed gas distributor 2-1, and part of the premixed gas Distributor 2-1 is connected with sub-fire ring 2-2, and sub-fire ring 2-2 is connected with steady flame baffle plate 2-6, and sub-fire ring 2-2 is provided with fire hole 2-4, and sub-fire ring 2-2 and Between the flame-stabilizing baffle plate 2-6 is the combustion flue 2-5, and the sub-fire ring 2-2 and the combustion flue 2-5 are in an annular structure with the flame-stabilizing baffle plate 2-6, and what is set in the middle of the ring is a complete preset The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com