A layered composite lightweight multifunctional industrial furnace wall structure

An industrial furnace and multi-functional technology, applied in the field of industrial heat preservation and energy saving, can solve the problems of high specific strength, poor thermal performance, high heat consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

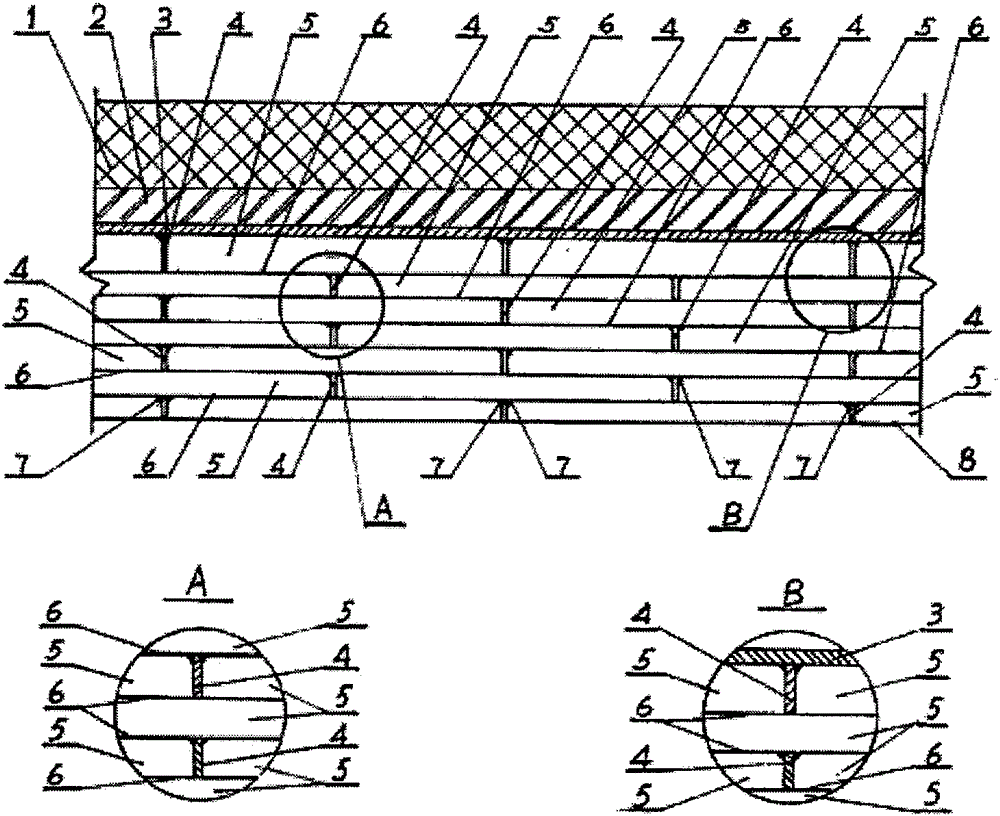

[0026] 1. Embodiment 1: Fabrication of steel inner shell

[0027] To implement the steel structure process specification, firstly, according to the requirements of the technical documents, the refractory steel plate with a thickness of 6mm4Cr9Si2 is sheared and blanked for a cylinder with a nominal diameter of φ1500mm and a height of 1800mm—processing weld bevel—rolling processing; The butt joint is welded according to the continuous weld seam, and the weld seam is guaranteed to be plump, free of slag inclusions, and free of cracks; the steel inner shell 3 is manufactured after out-of-roundness correction and quality inspection.

Embodiment 2

[0028] 2. Embodiment 2. Manufacturing of multi-reflection heat insulation structure and stiffening cylinder

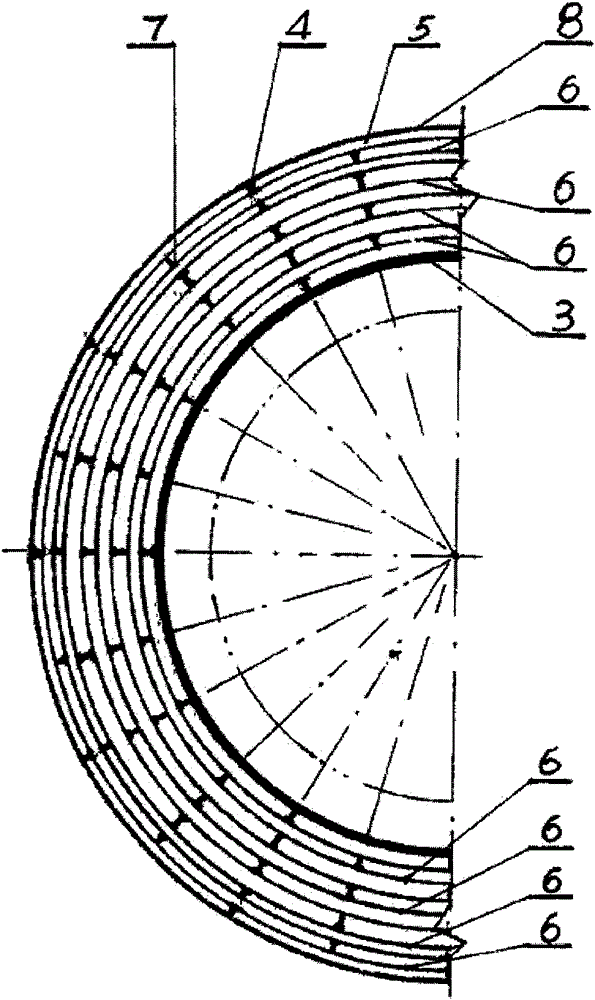

[0029] According to the calculation of function and structure, the reflective insulation structure has a total of 11 layers from the inside to the outside. The air space layer of the first layer is 50mm, and the second layer to the tenth layer are all 20mm. The eleventh layer uses aluminum alloy mesh as the positioning support adjustment part. The nominal outer diameter is φ2000mm.

[0030] The first weight: (1) Distribute six axially ribbed steel strips with a thickness of 4mm, a width of 50mm, and a length of 1800mm evenly along the outer circle of the steel inner shell, perpendicular to the surface, and perform staggered intermittent welding from both sides, and the length of the fillet weld is 20mm , spacing 30mm, weld height 4mm, a total of 36 sections;

[0031] (2) Cut 3 steel rings with a width of 50 mm and a thickness of 4 mm that have been prepared, and cut t...

Embodiment 3

[0037] 3. Example 3. Construction of shaped fire-resistant and heat-insulating inner lining

[0038] Construction takes place inside the steel inner shell. The refractoriness of the selected refractory brick material should be 200°C higher than the temperature of the molten metal, and the thickness of the heat-insulating inner lining layer of the refractory brick to ensure that the working temperature of the steel inner shell 3 is ≤1000°C. The construction process is as follows: the prepared hollow The wall function enclosure structure is laid flat and constructed inside the steel inner shell 3 . First, use ASC (aluminum oxide-silicon carbide-C) bricks with a density of 2-8t / m3 to build the bottom, then build arcs from the bottom to both sides, and finally build bricks to the top. Pour a layer of high-aluminum refractory castables to level the wall, and then lay bricks. The brick joints between rows should be staggered, and the joints between bricks are all 2mm, and finally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com