Novel method and device for detecting evaporation loss of lubricating oil

A technology of evaporation loss and lubricating oil, which is applied in the direction of weighing by removing certain components to achieve accurate measurement results, reduce injury to measurement personnel, and overcome pollution problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

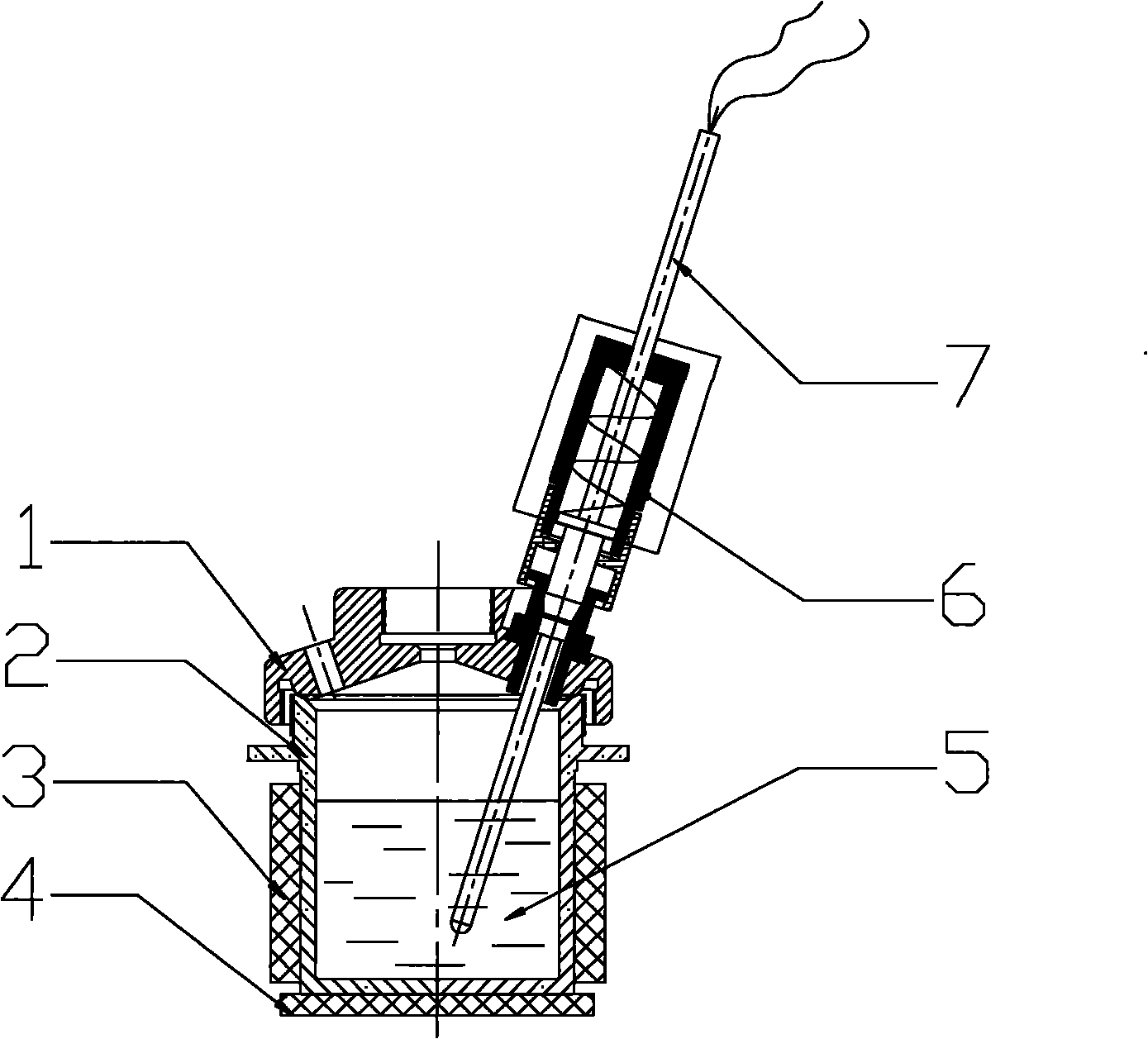

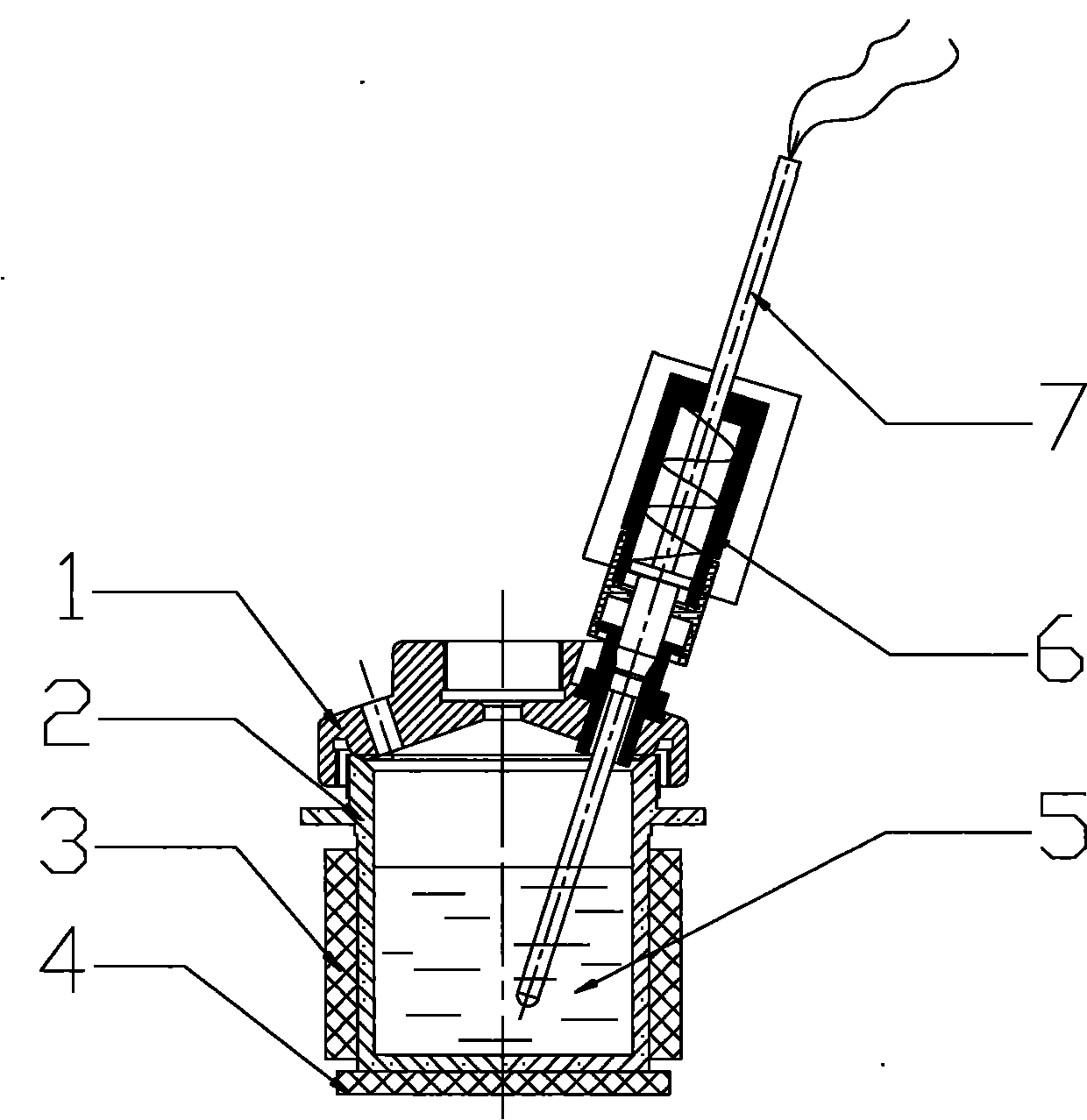

[0023] The present invention combines the flexible heating body with the ceramic flat heating body, uses PID fuzzy control, quickly heats the sample to the actual test temperature within the time T, and can maintain the temperature control accuracy of 245.2±0.5°C until the test is completed, specifically The method steps are as follows:

[0024] 1. Prepare other necessary test conditions stipulated by the "Noack" method, including: weighing the sample, connecting the pipeline, preparing the evaporating dry pot, adjusting the vacuum degree, and connecting to the thermostat;

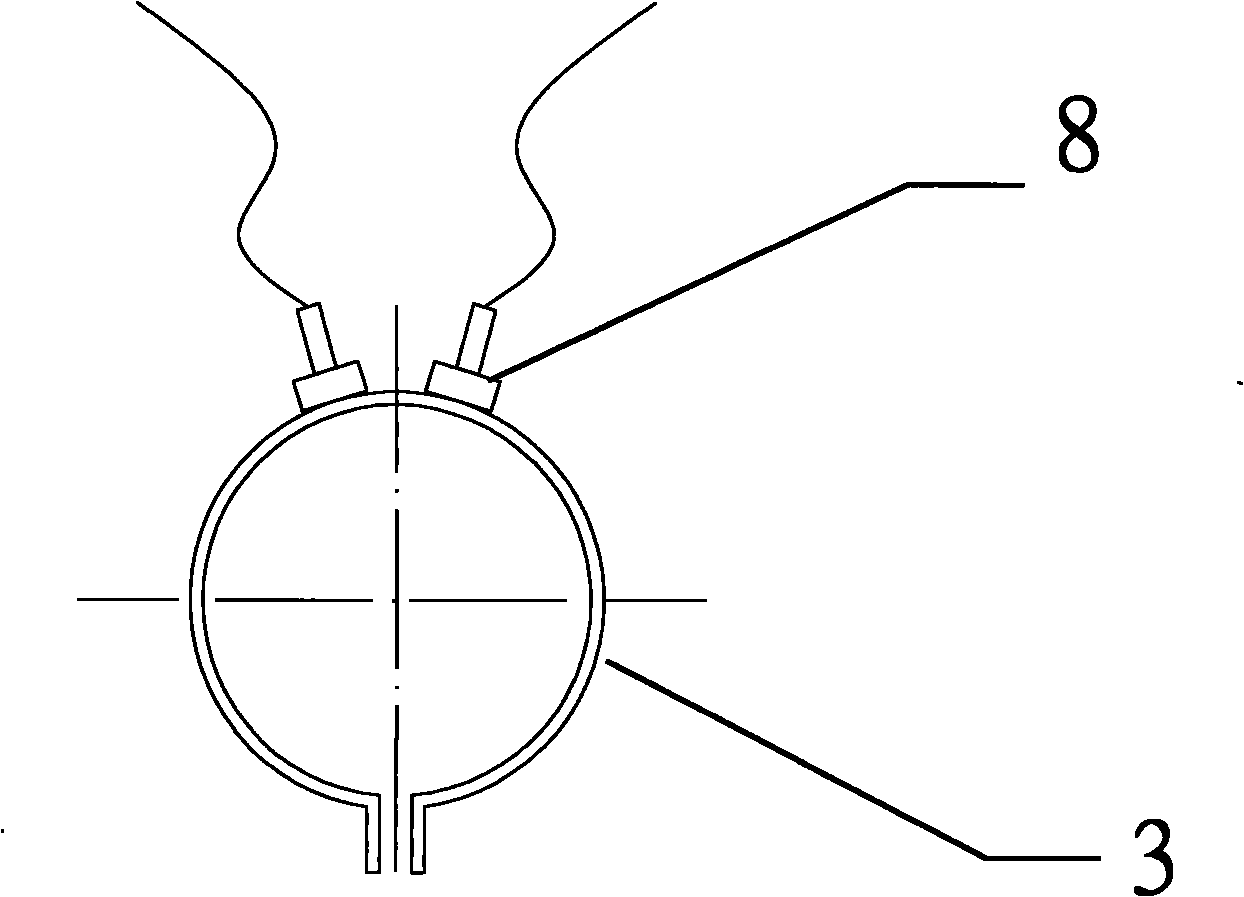

[0025] 2. Put the evaporating dry pot into the flexible heating body, ensure that the flexible heating body wraps the dry pot tightly, and the bottom of the dry pot should be in good contact with the flat high-efficiency heating body;

[0026] 3. At the beginning of the test, the temperature control system automatically controls the heating rate of the sample to ensure that it reaches 245.2±0.5°C within th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com