Soft measurement method of quality index data in rubber mixing process of internal mixer

A quality index, rubber mixing technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the lack of soft measurement modeling method of mixing process, high computational complexity, and inability to effectively track rubber online Problems such as the time-varying characteristics of the mixing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

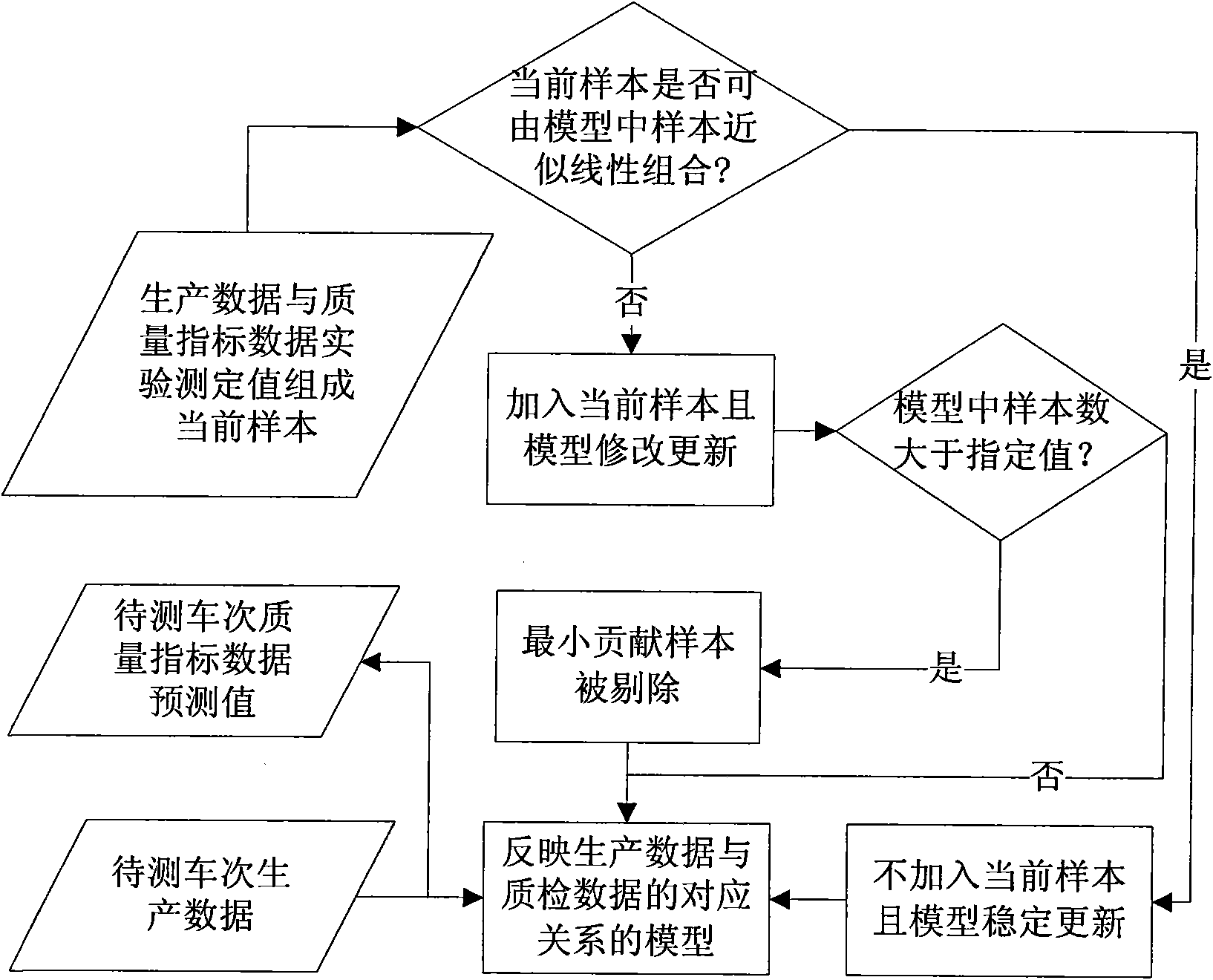

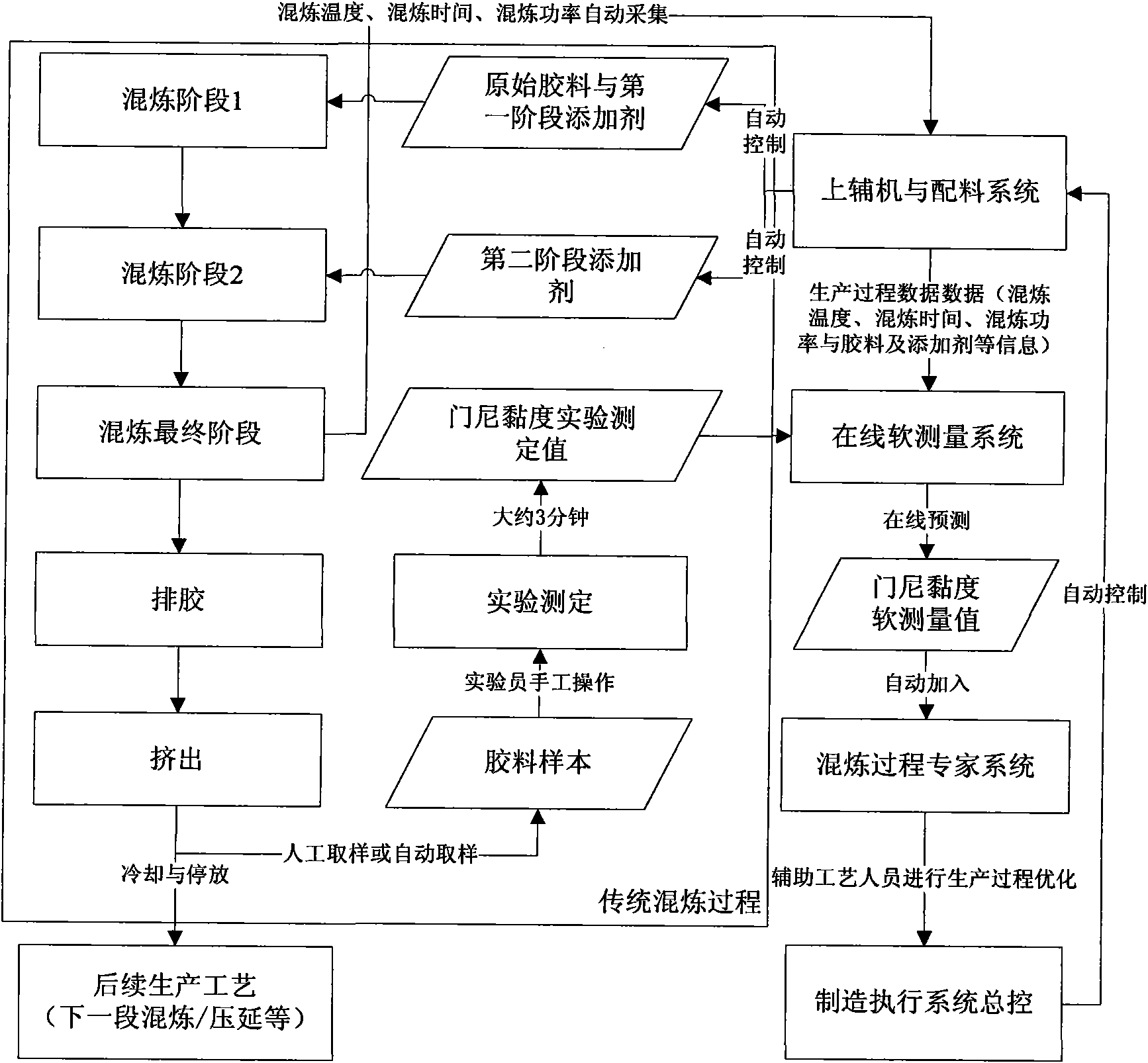

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited thereto.

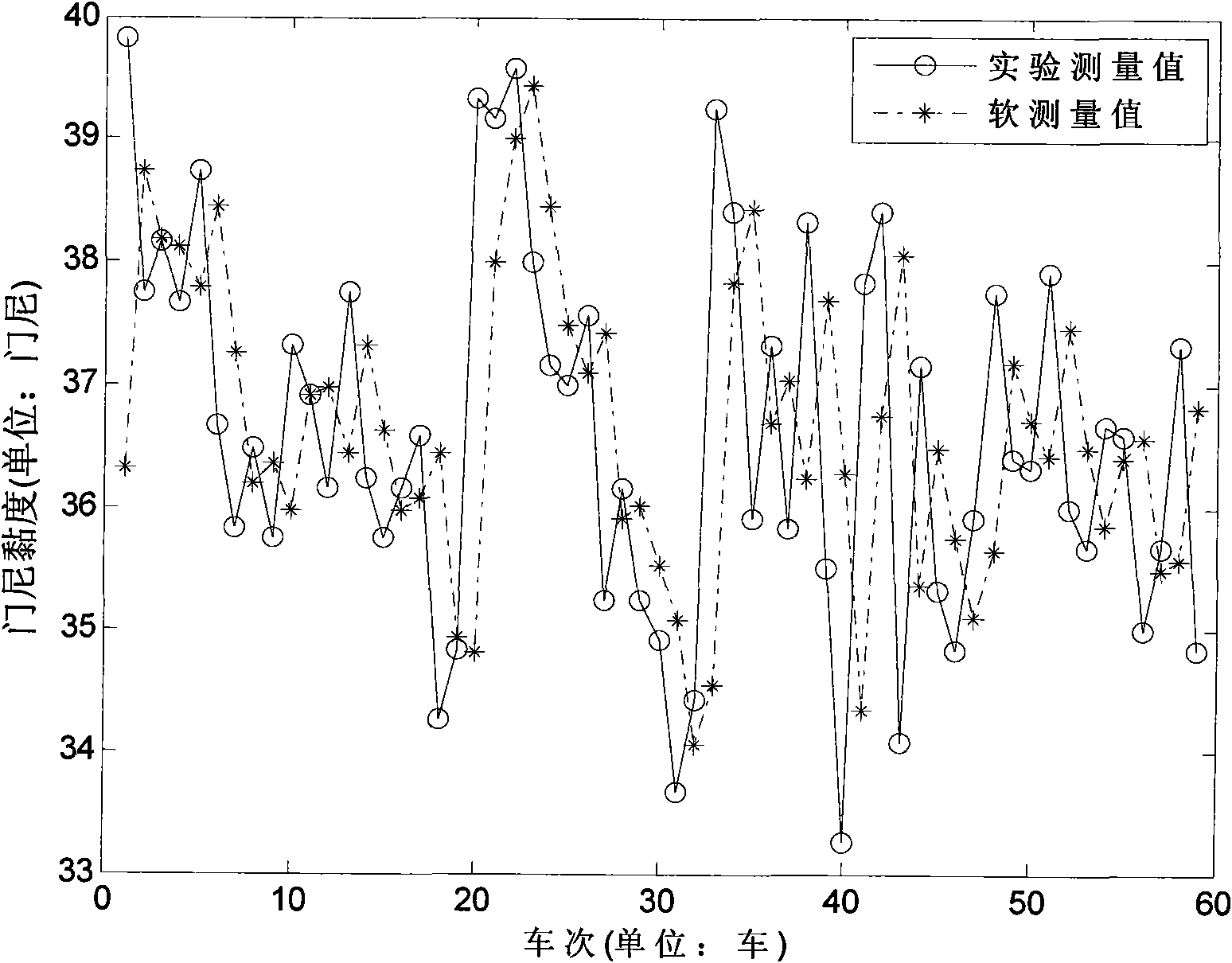

[0079] There are a lot of production process data in the rubber mixing process, including mixing time, temperature, energy consumption, pressure, rubber hardness, mixing process, formula, etc. Reasonable and effective selection of these features to form the input sample feature space is of great significance for modeling. On the one hand, introducing too many features will increase the collection of industrial production data, increase the calculation intensity and make the model more complex, and when some features can be linearly represented by other features, this calculation is redundant; on the other hand On the one hand, when some important features are not selected, it will lead to inaccurate model establishment. In response to the above problems, when performing feature selection, we use the Ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com