Connecting terminal for rotary transformer and manufacturing method thereof

A technology of rotary transformers and terminals, applied in the manufacture of transformers, contacts, transformer/inductor coils/windings/connections, etc., can solve the problems of easily damaged windings and high cost, reduce production costs, save materials, improve The effect of job stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

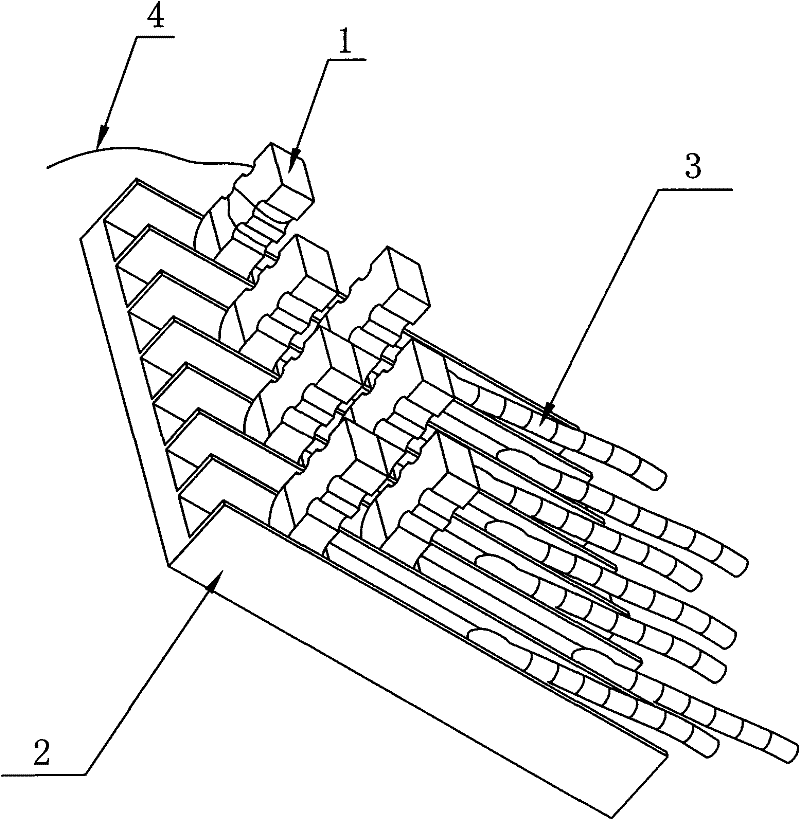

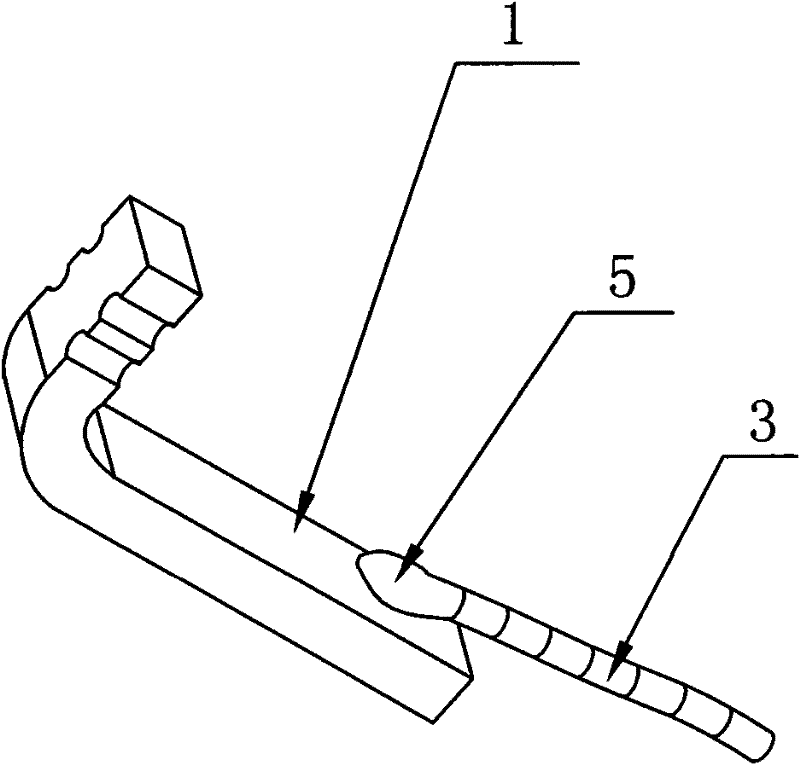

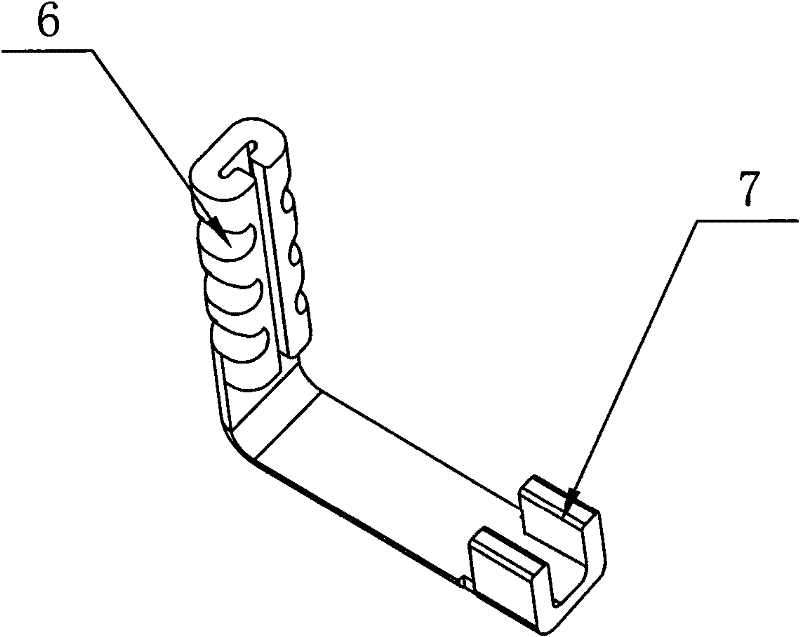

[0022] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings. Such as figure 1 As shown, it is a schematic diagram of the lead wire structure of the existing resolver, including a base 2, and at least one terminal 1 installed on the base 2, combined with figure 2 As shown, the shape of the terminal 1 is "L", wherein the terminal 1 includes a first end and a second end, the first end is connected to the winding lead wire 4 of the resolver, and the second end is connected to the external connector lead wire 3. The winding lead wire 4 of the resolver is wound on the first end of the terminal 1 by winding, and the lead wire 3 of the connector is connected to the second end of the terminal 1 by welding (spot welding). The power signal can be introduced into the winding of the rotary transformer through the connector and the terminal 1 so that the rotary transformer can work normally. The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com