Reliable contact

A contact and active area technology, applied in the field of improved formation of nickel-based germanide contact, can solve problems such as disadvantage and high annealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

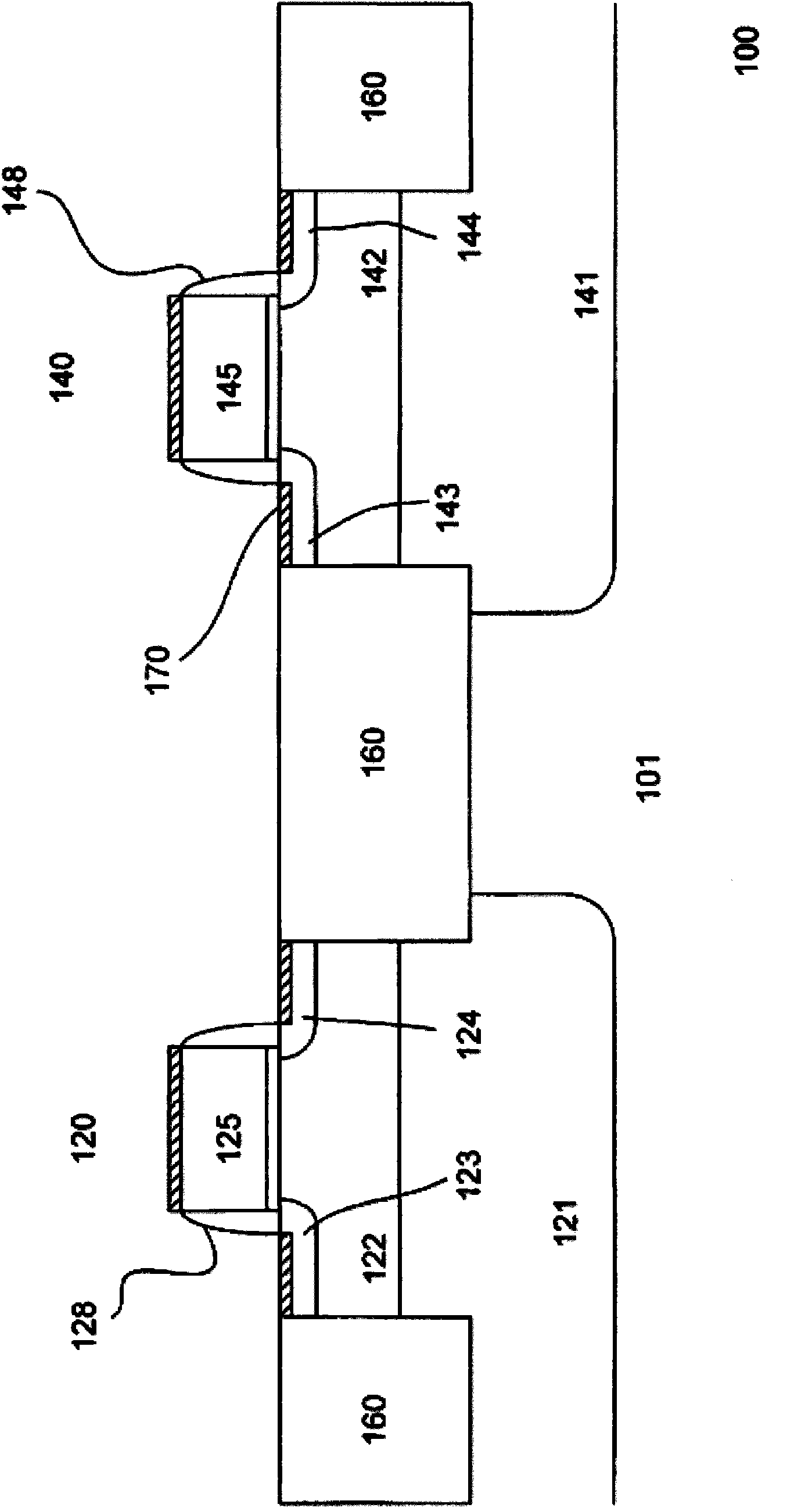

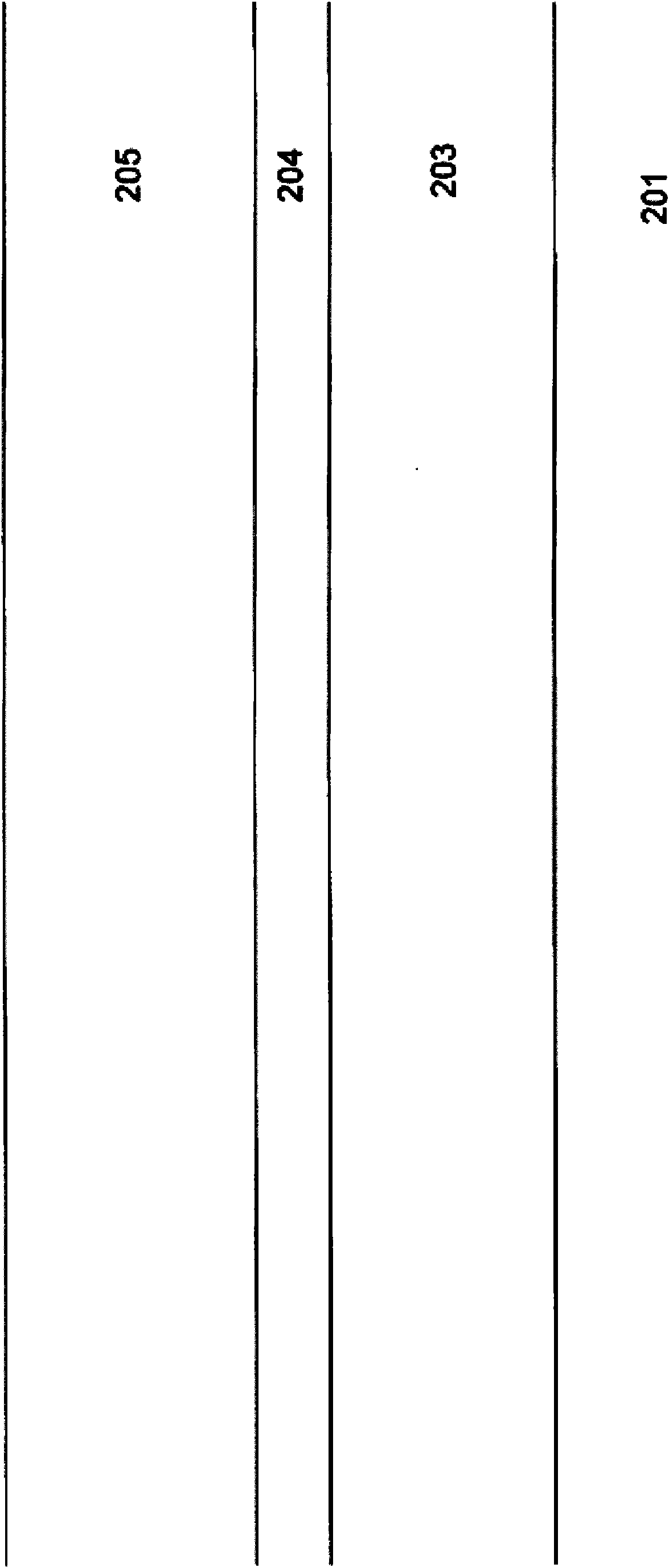

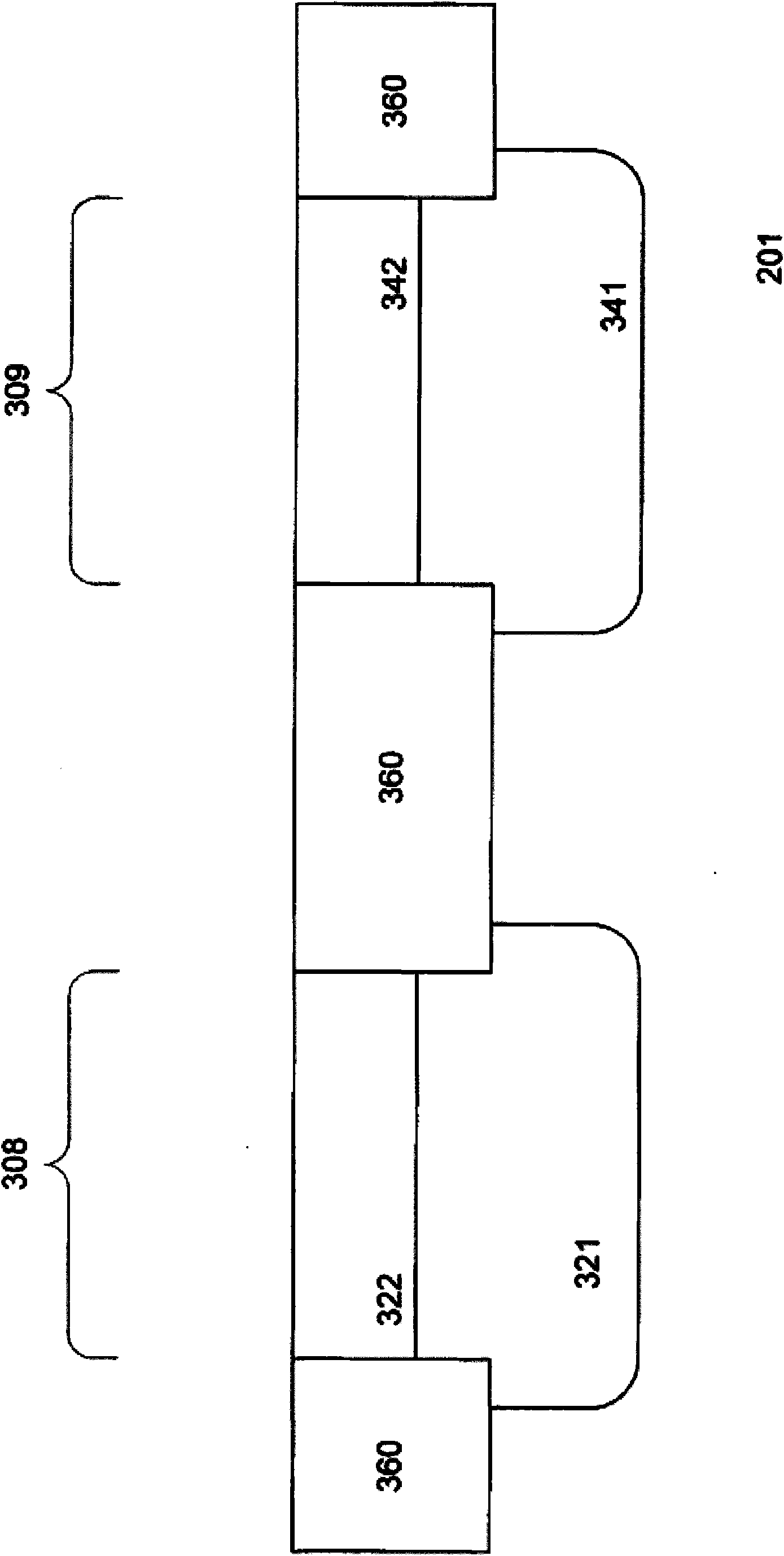

[0011] Figure 2-6 A process for forming a nickel-based contact according to one embodiment of the present invention is shown. refer to figure 2 , shows a cross-section of a portion of the substrate 201 . The substrate is used to form integrated circuit packages. In one embodiment, the substrate comprises a multilayer substrate in which at least the top or surface layer comprises germanium. For example, multilayer substrates include germanium-on-insulator substrates. The germanium-on-insulator substrate may comprise a silicon substrate substrate 203 having a top layer 205 comprising germanium separated by an insulator layer 204 such as silicon dioxide. The top layer of the substrate comprises, for example, single crystalline material, polycrystalline or amorphous material, or combinations thereof. The germanium layer can be tensioned or relaxed. A surface comprising germanium may also be provided on the silicon germanium substrate layer.

[0012] In another embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com