Housing for a centrifugal compressor

A compressor and radial flow technology, applied in the field of radial compressor casing, can solve problems such as damaged components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

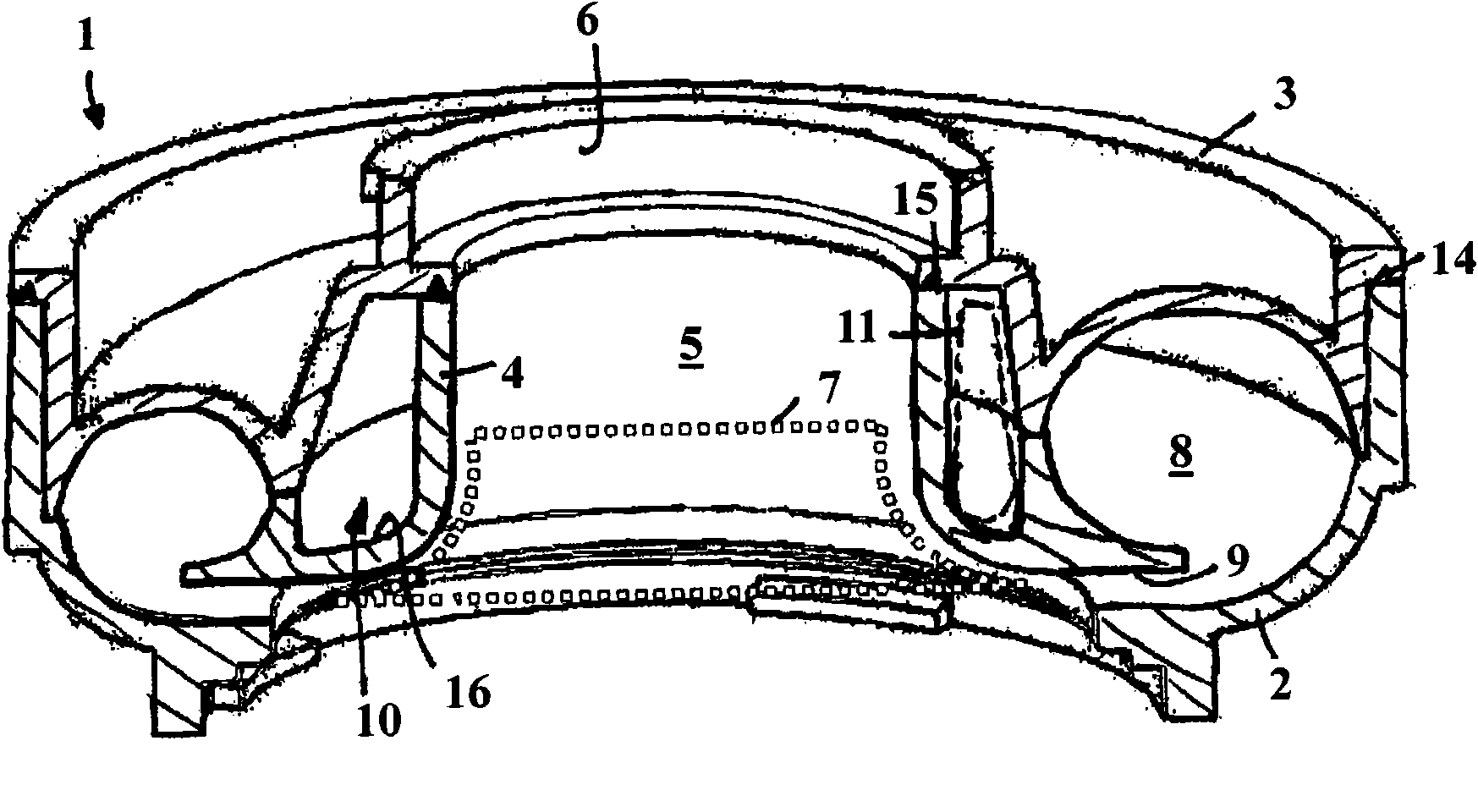

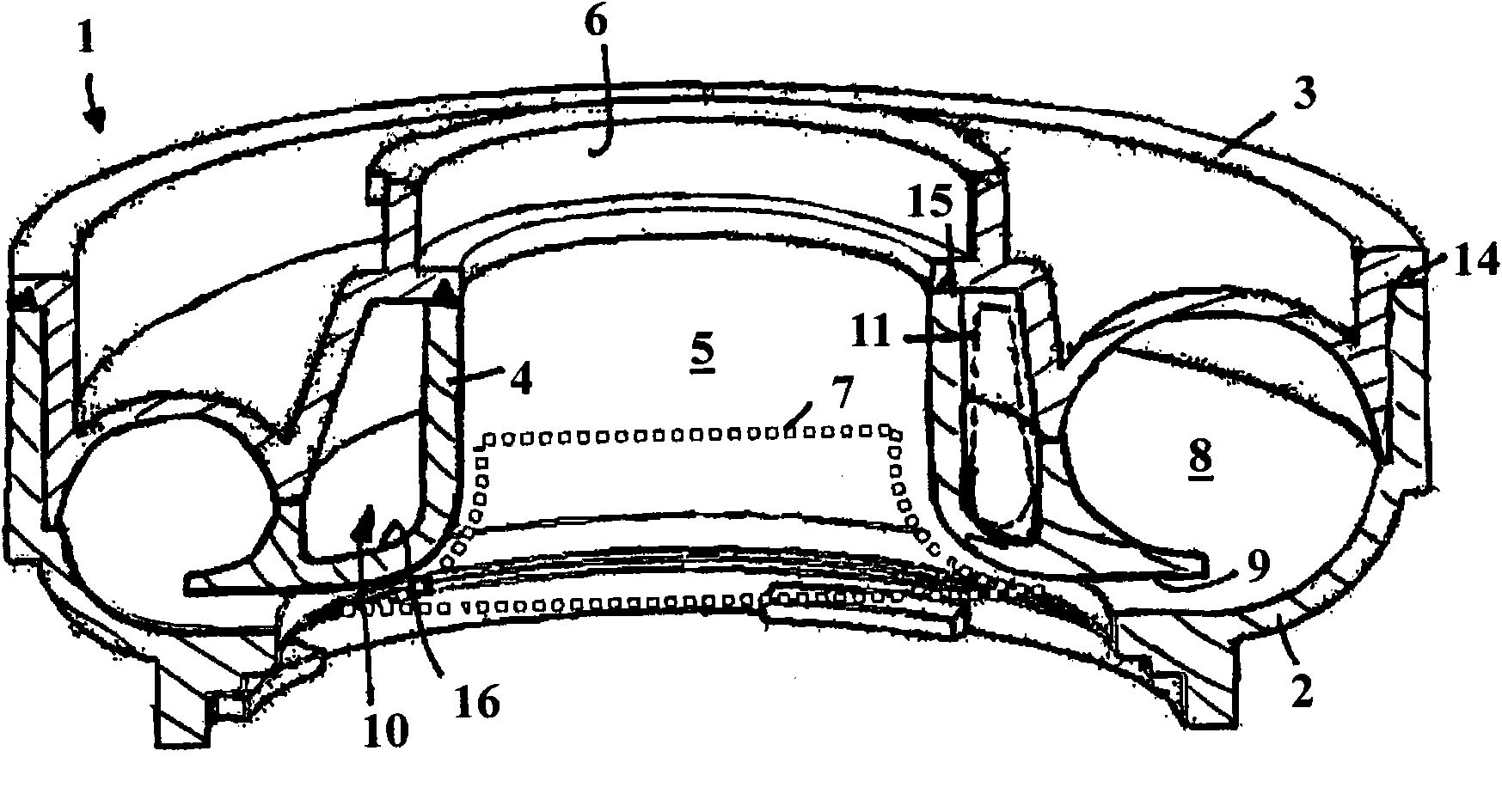

[0017] The illustrated housing 1 for a radial compressor is a component of an exhaust gas turbocharger of an internal combustion engine, in which the exhaust gas of the internal combustion engine drives a turbine wheel connected in a rotationally fixed manner to a compressor wheel, which The impeller is rotatably supported in the casing 1 . Through the rotation of the compressor wheel, the combustion air is sucked in in the suction section and compressed to a higher charge pressure, at which point the combustion air is supplied to the cylinders of the internal combustion engine.

[0018] The housing 1 is constructed in three parts and comprises a compressor rear wall 2, a compressor front 3 and inside a support shell 4 which delimits a compressor wheel accommodation space for accommodating and supporting the compressor wheel 5. The compressor wheel is provided with the reference numeral 7 in this exemplary embodiment and is shown only implicitly in dashed lines. The combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com